Film plating method for forming colorful films through PET films, and application of PET films to glass cover plates

A color film and coating technology, which is applied to the coating of PET film to form colorful film, and the application field of glass cover plate, can solve the problems of multiple raw materials, the difference of the refractive index of the colorful film layer is reduced, and the processing technology is cumbersome. Achieve the effect of saving raw materials and shortening processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

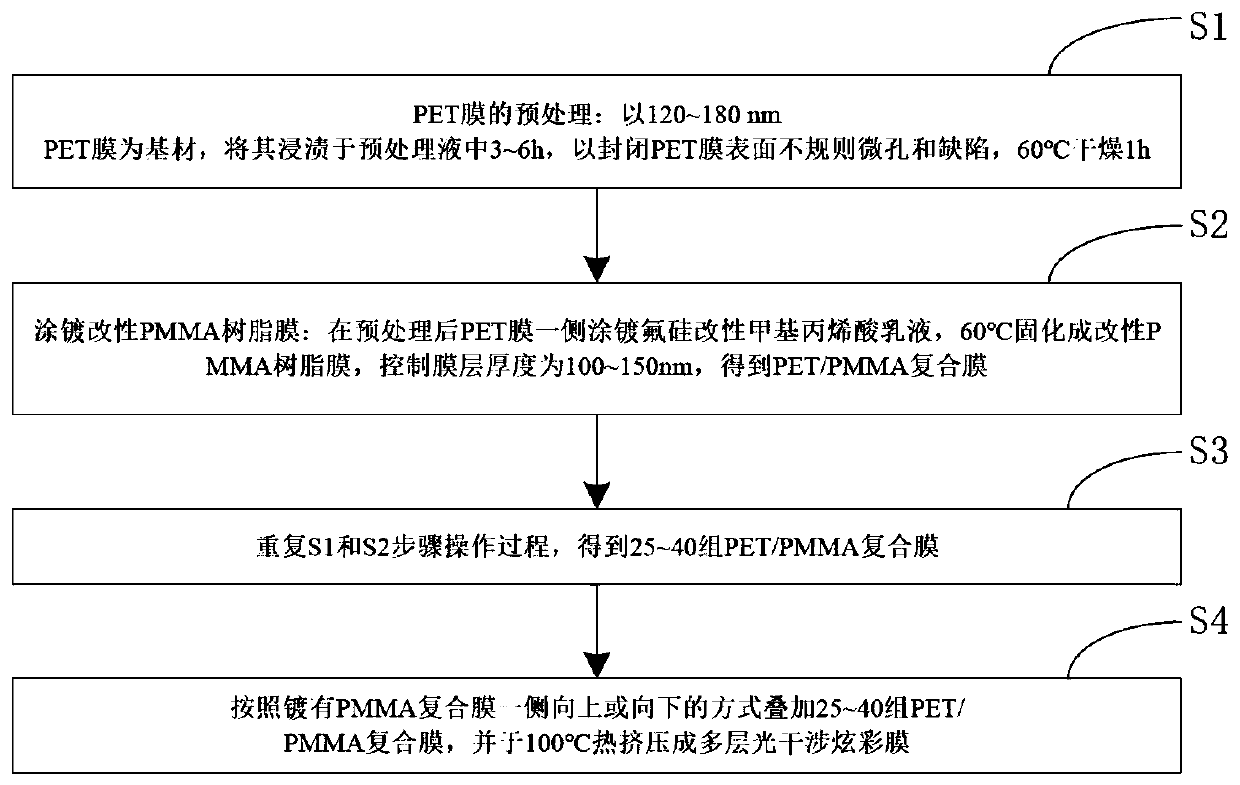

[0024] A method for coating a PET film to form a colorful film, comprising the following steps:

[0025] S1: Pretreatment of PET film: use 120nm PET film as the substrate, immerse it in the pretreatment solution for 3 hours to seal the irregular micropores and defects on the surface of the PET film, and dry at 60°C for 1 hour;

[0026] The pretreatment liquid includes the following components in parts by weight: 20 parts of nano-alumina sol, 10 parts of polyether modified silicone oil, 5 parts of heptadecafluorodecyltriethoxysilane, 1 part of sodium lauryl sulfate, emulsified 0.5 part of agent;

[0027] S2: Coating modified PMMA resin film: After pretreatment, one side of the PET film is coated with fluorine-silicon modified methacrylic acid emulsion, cured at 60°C to form a modified PMMA resin film, and the thickness of the film layer is controlled to 100nm to obtain PET / PMMA Composite film;

[0028] S3: Repeat steps S1 and S2 to obtain 30 groups of PET / PMMA composite films...

Embodiment 2

[0031] A method for coating a PET film to form a colorful film, comprising the following steps:

[0032] S1: Pretreatment of PET film: use 140nm PET film as the substrate, immerse it in the pretreatment solution for 6 hours to seal the irregular micropores and defects on the surface of the PET film, and dry at 60°C for 1 hour;

[0033] The pretreatment liquid includes the following components by weight: 25 parts of nano-alumina sol, 15 parts of polyether modified silicone oil, 7.5 parts of heptadecafluorodecyltriethoxysilane, 2 parts of fatty alcohol polyoxyethylene ether, emulsified Dosage TX-1001 part;

[0034] S2: Coating modified PMMA resin film: After pretreatment, one side of the PET film is coated with fluorine-silicon modified methacrylic acid emulsion, cured at 60°C to form a modified PMMA resin film, and the thickness of the film layer is controlled to 110nm to obtain PET / PMMA Composite film;

[0035] S3: Repeat steps S1 and S2 to obtain 35 groups of PET / PMMA compo...

Embodiment 3

[0038] A method for coating a PET film to form a colorful film, comprising the following steps:

[0039] S1: Pretreatment of PET film: use 150nm PET film as the substrate, immerse it in the pretreatment solution for 6 hours to seal the irregular micropores and defects on the surface of the PET film, and dry at 60°C for 1 hour;

[0040] The pretreatment liquid includes the following components in parts by weight: 30 parts of nano-alumina sol, 20 parts of polyether modified silicone oil, 10 parts of heptadecafluorodecyl triethoxysilane, 3 parts of sodium alkyl sulfosuccinate , emulsifier TX-1002 parts;

[0041] S2: Coating modified PMMA resin film: After pretreatment, one side of the PET film is coated with fluorine-silicon modified methacrylic acid emulsion, cured at 60°C to form a modified PMMA resin film, and the thickness of the film layer is controlled to 100nm to obtain PET / PMMA Composite film;

[0042] S3: Repeat steps S1 and S2 to obtain 40 groups of PET / PMMA composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com