A Method for Immobilizing High Aspect Ratio Micro/Nano Structures Based on Gel Interaction

A technology of micro-nano structure and gelation, applied in micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve problems such as structural failure, achieve the effect of preventing failure, improving yield, and optimizing process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

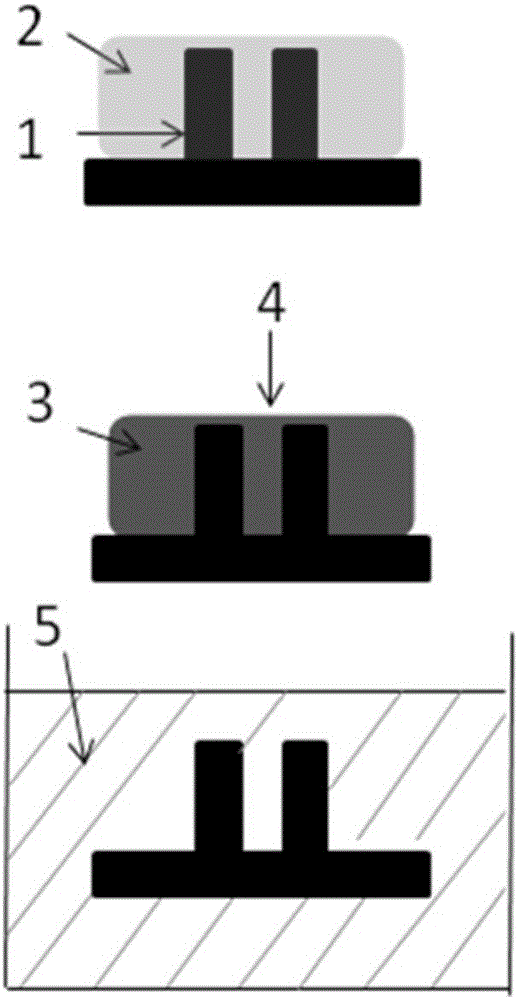

[0028] Example 1, gel immobilization of high aspect ratio micro-nanostructures for observation

[0029] 1. Prepare a hot solution of carrageenan with a mass concentration of 1%: 1g of carrageenan, 100ml of water, and heat to dissolve at 90°C;

[0030] 2. Take the 2-inch silicon wafer containing the micro-nano structure with large aspect ratio out of the developer solution and place it in deionized water. Take it out after 1 minute, and quickly add 5 ml of prepared gellan gum on the surface to heat it. solution;

[0031] 3. At room temperature, first put the silicon wafer on the gel-spinning table to cool for 30 seconds, and then spin-coat according to the set gel-spinning machine parameters: first spin-coat at 1000r / min for 10 seconds; then spin at 2000r / min Apply for 20 seconds. After the spin coating is completed, let it stand for 1 minute to obtain a fixed gel layer and form a gel-fixed micro-nano structure;

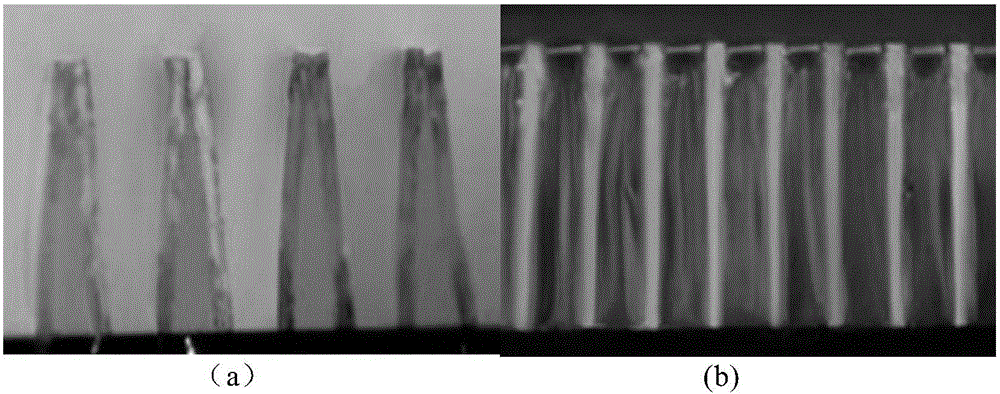

[0032] 4. Observe the silicon wafer under a microscope, and c...

Embodiment 2

[0034] Example 2, gel immobilization of large aspect ratio micro-nanostructures for electroplating

[0035] 1. Prepare gellan gum hot solution with a concentration of 0.6%: gellan gum 0.6g, water 100ml, heat to dissolve at 80°C;

[0036] 2. Take the 2-inch silicon wafer containing the micro-nano structure with large aspect ratio out of the developer solution and place it in deionized water. Take it out after 1 minute, and quickly add 5 ml of prepared gellan gum on the surface to heat it. solution;

[0037] 3. At room temperature, first put the silicon wafer on the gel-spinning table to cool for 30 seconds, and then spin-coat according to the set gel-spinning machine parameters: first spin-coat at 1000r / min for 10 seconds; then spin at 2000r / min Apply for 20 seconds. After the spin coating is completed, let it stand for 30 seconds to obtain a fixed gel layer and form a gel-fixed micro-nano structure;

[0038] 4. After placing the silicon wafer under a microscope for observat...

Embodiment 3

[0041] Example 3, gel immobilization of large aspect ratio micro-nanostructures for observation

[0042] 1. Prepare a carrageenan hot solution with a mass concentration of 0.8%: carrageenan 0.8g, water 100ml, heat to dissolve at 90°C;

[0043] 2. Take out the 2-inch silicon wafer containing the micro-nano structure with large aspect ratio from the developer solution and place it in deionized water, take it out after 1 minute, and quickly put it into the prepared hot carrageenan solution;

[0044] 3. After standing for 1 minute, pull up the silicon wafer vertically at a speed of 5mm / s, and let it stand for 5 minutes at room temperature to obtain a fixed gel layer and form a gel-fixed micro-nano structure;

[0045] 4. Observe the silicon wafer under a microscope, and conduct process evaluation by detecting the micro-nano structure;

[0046] 5. Place the observed silicon wafer in an 80°C water bath and shake gently for 2 minutes, and the gel between the micro-nano structures can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com