Self-heating type methanol reforming hydrogen production equipment

A reforming hydrogen production and self-heating technology, applied in hydrogen, hydrogen/synthesis gas production, inorganic chemistry, etc., can solve the problem of difficulty in ensuring uniform heating of reaction gas, poor filling of granular catalysts, and pressure resistance of gas flow Large and other problems, to achieve good catalytic performance, convenient filling process, uniform self-heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

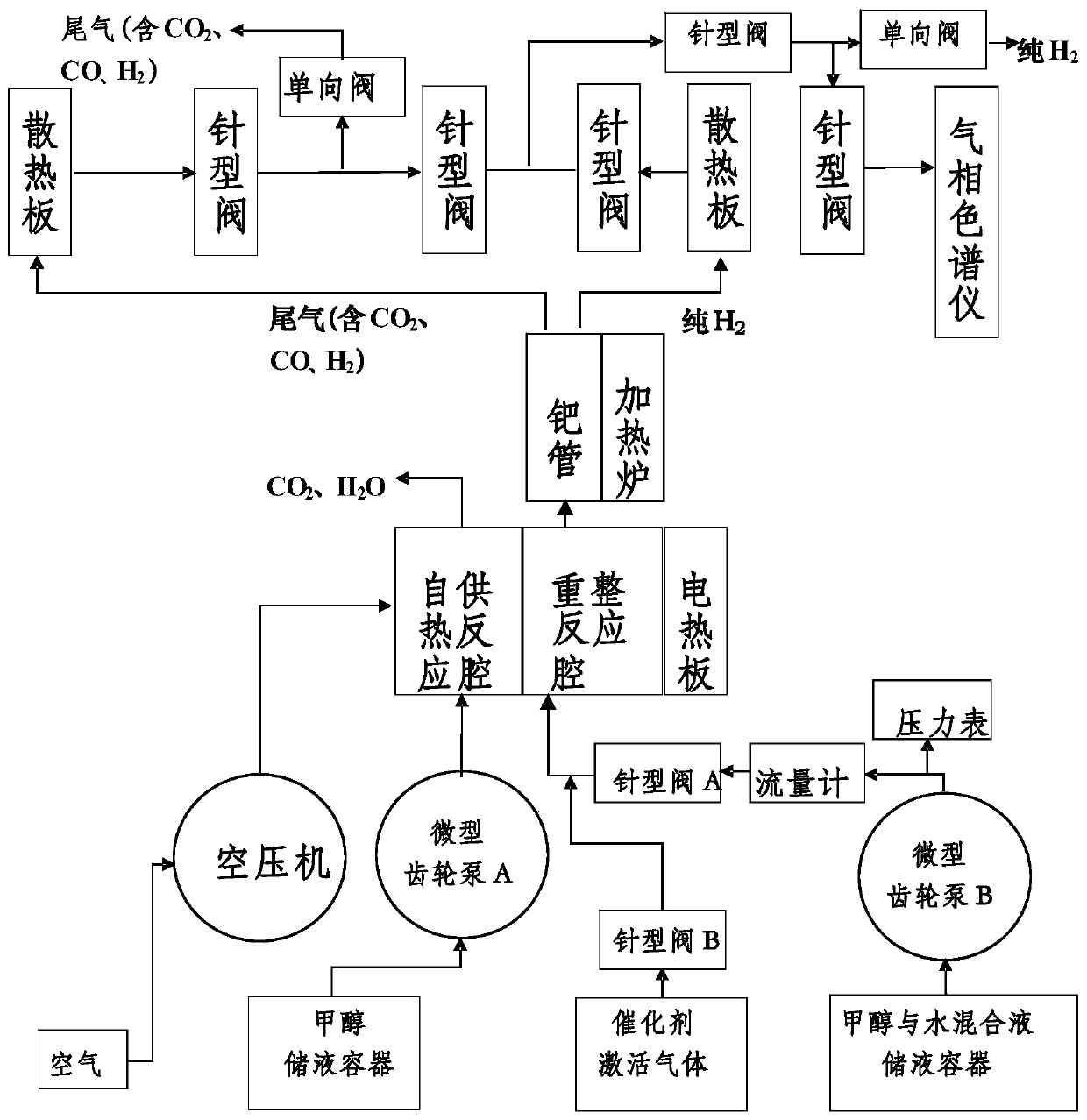

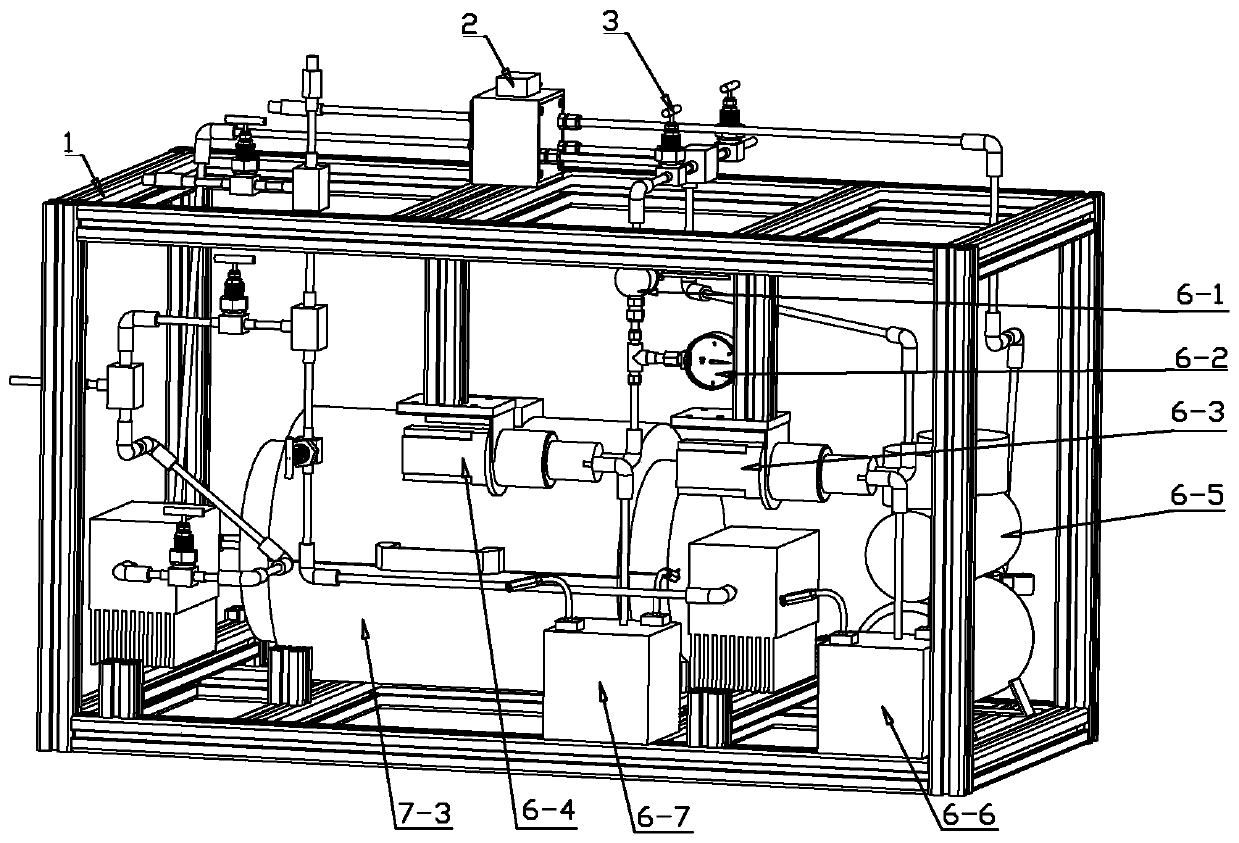

[0040] Such as figure 1 , a self-heating type methanol reforming hydrogen production equipment of this embodiment is arranged in a rectangular frame profile 1, including a raw material supply module, a catalyst activation module 3, a reactor module 2 and a hydrogen purification module, the raw material supply module , The catalyst activation module 3 is connected to the reactor module 2, and the reactor module 2 is connected to the hydrogen purification module;

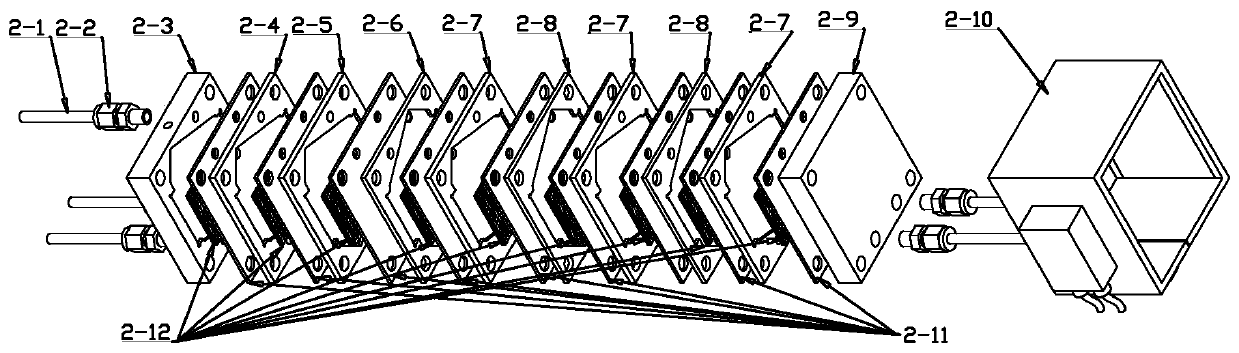

[0041] The reactor module 2 includes a self-heating reaction chamber, a reforming reaction chamber and an electric heating plate 2-10, the self-heating reaction chamber and the reforming reaction chamber are connected in sequence, and the self-heating reaction chamber Supplying heat to the reforming reaction chamber, the electric heating plate 2-10 is wrapped around the self-heating reaction chamber and the periphery of the reforming reaction chamber;

[0042] The self-heating reaction chamber and the reforming react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com