Preparation method of epitaxial high-conductivity BFCO photoelectric solid solution film and epitaxial high-conductivity BFCO photoelectric solid solution film prepared by using same

A high-conductivity, thin-film technology, applied in the field of law, can solve problems such as less research, achieve the effect of high degree of epitaxy, meet research and development needs, and good semiconductor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

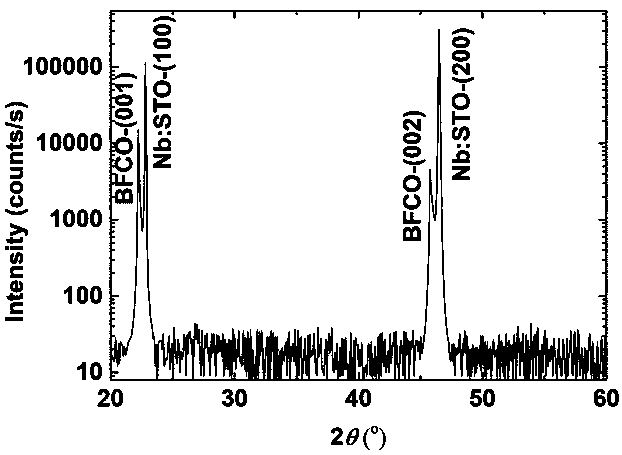

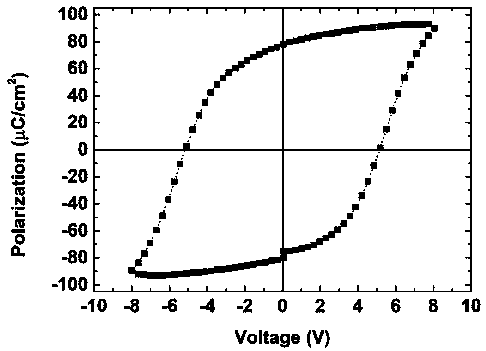

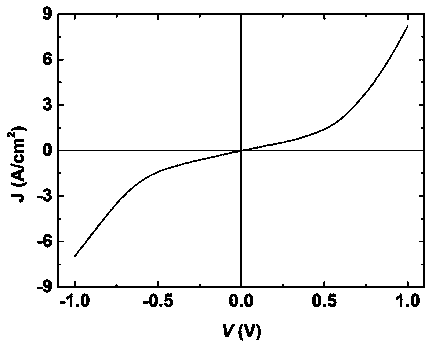

[0032] High conductance BiFe 0.7 co 0.3 o 3-δ The preparation of photoelectric solid solution epitaxy thin film, the steps are as follows:

[0033] 1. Configuration of precursor solution

[0034] Bi(NO 3 ) 3 ∙5H 2 O solid powder was added to glacial acetic acid (CH 3 COOH) (Bi: glacial acetic acid molar ratio is 1:8), continuously stirred on a magnetic stirrer for 8 h, and kept the temperature at 50 °C until the solution was a transparent solution, Fe(NO 3 ) 3 ∙9H 2 O was added to the above solution, and the stirring was continued on a magnetic stirrer until the Fe(NO 3 ) 3 ∙9H 2 O is completely dissolved, and then Co(NO 3 ) 2 ∙6H 2 O was added to the solution, keeping the temperature at 50 °C, and stirred until completely dissolved. Then add polyethylene glycol 20000, polyethylene glycol 400 and acetylacetone according to the molar ratio of bismuth iron cobaltate: polyethylene glycol 20000: polyethylene glycol 400: acetylacetone=1: 0.01%: 0.01%: 1, Finally add...

Embodiment 2

[0042] High conductance BiFe 0.7 co 0.3 o 3-δ The preparation of photoelectric solid solution epitaxy thin film, the steps are as follows:

[0043] 1. Configuration of precursor solution

[0044] With embodiment 1.

[0045] 2. Coating machine throwing film

[0046] (100) Nb:SrTiO 3 The substrate is placed in a tube furnace at 700 o C under heat treatment for 30 minutes, then keep the temperature at 80 o C and put it into a homogenizer, keep the humidity range at 11-15%, then apply the precursor solution on the substrate, and prepare a single-layer film by spin coating; wherein, the first layer of film is thrown at a speed of 7000rpm , the time is 2 minutes, and the film thickness is about 10-14 nm; the second-third film is spun at a speed of 5000rpm, the time is 1 minute, the film thickness is about 16-21 nm, and the other layers are spun at a speed of 6000rpm film, the time is 1 minute, and the film thickness is guaranteed to be around 12-17 nm;

[0047] 3. Heat trea...

Embodiment 3

[0052] High conductance BiFe 0.7 co 0.3 o 3-δ The preparation of photoelectric solid solution epitaxy thin film, the steps are as follows:

[0053] 1. Configuration of precursor solution

[0054] With embodiment 1.

[0055] 2. Coating machine throwing film

[0056] (100) Nb:SrTiO 3 The substrate is placed in a tube furnace at 700 o C under heat treatment for 30 minutes, then keep the temperature at 80 o C and put it into a homogenizer, keep the humidity range at 11-15%, then apply the precursor solution on the substrate, and prepare a single-layer film by spin coating; wherein, the first layer of film is thrown at a speed of 6000rpm , the time is 2 minutes, and the film thickness is about 13-15 nm; the second-third film is spun at a speed of 4000rpm, the time is 1 minute, and the film thickness is about 18-25nm, and the other layers are spun at a speed of 5000rpm , the time is 1 minute, and the film thickness is guaranteed to be around 15-20;

[0057] 3. Heat treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com