A polymer-assisted epitaxial growth bifeo 3 Multiferroic Thin Film Method

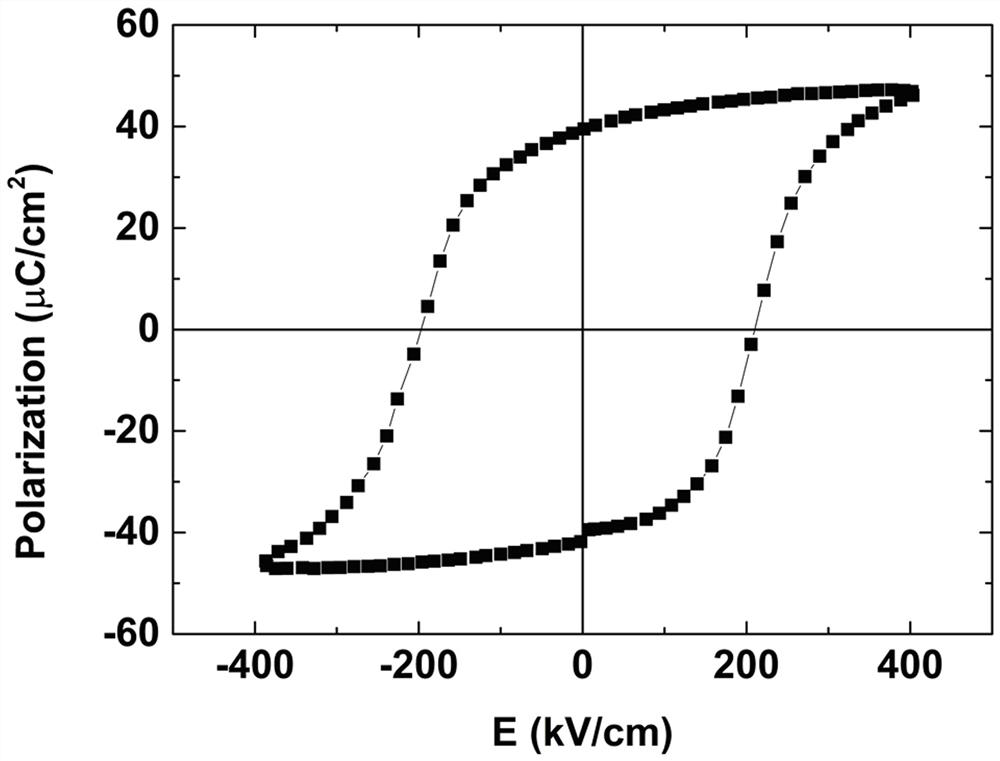

A polymer-assisted, epitaxial growth technology, applied in the field of epitaxially grown BiFeO3 multiferroic thin films, to achieve the effects of high epitaxy, large room temperature electric polarization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

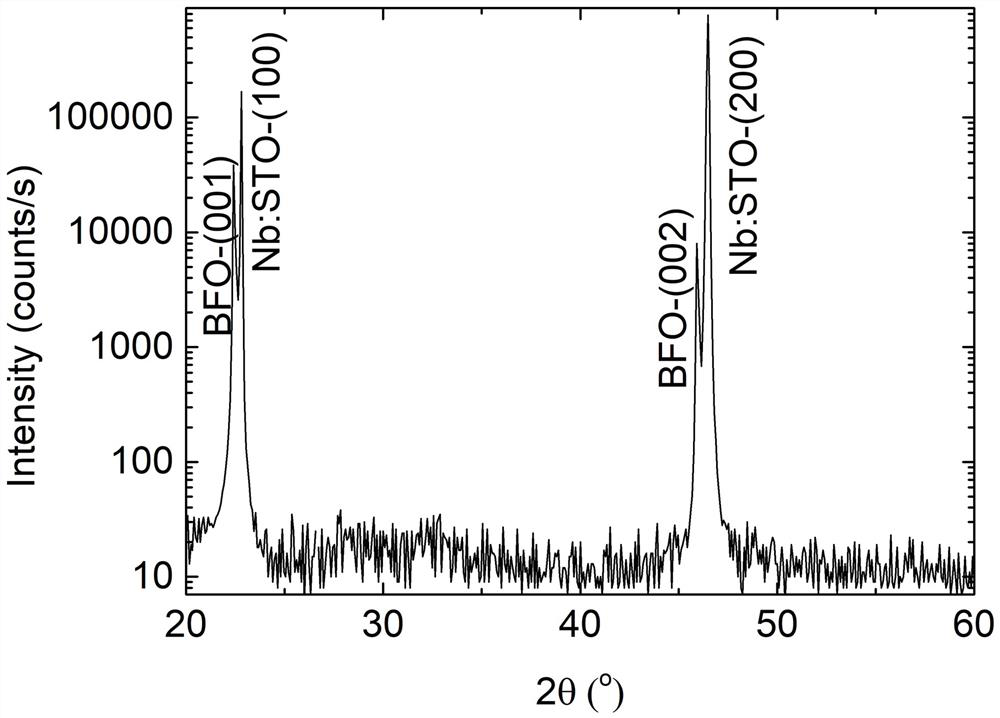

[0031] BiFeO 3 The preparation of epitaxial film, the steps are as follows:

[0032] 1. Configuration of precursor solution

[0033] Bi(NO 3 ) 3 ∙5H 2 O solid powder was added to glacial acetic acid (CH 3 COOH) (Bi: glacial acetic acid molar ratio is 1:8), continue to stir on a magnetic stirrer for 7-9h, and keep the temperature at 45-50°C until the solution is a very viscous transparent solution, which will be mixed with Bi( NO 3 ) 3 ∙5H 2 Fe(NO 3 ) 3 ∙9H 2 O was added to the solution, and the stirring was continued on a magnetic stirrer for 2 h until the Fe(NO 3 ) 3 ∙9H 2 O is completely dissolved, then add polyethylene glycol 20000 and polyethylene glycol 400 according to the molar ratio of bismuth ferrite: polyethylene glycol 20000: polyethylene glycol 400 = 1: 0.01%: 0.01%, and finally add an equal volume ratio Dilute the solution of ethylene glycol and ethylene glycol methyl ether into the BiFeO 3 The concentration of the solution is 0.23 mol / L. After full...

Embodiment 2

[0043] BiFeO 3 The preparation of thin film, steps are as follows:

[0044] 1. Configuration of precursor solution

[0045] With embodiment 1.

[0046] 2. Coating machine throwing film

[0047] (100) Nb:SrTiO 3 The substrate was put into a tube furnace for heat treatment at 700 °C for 30 minutes, then kept at 80 °C and placed in a glue homogenizer, and kept at a humidity range of 14-17%, then the precursor solution was coated on the substrate, passed A single-layer film was prepared by spin coating; wherein, the first layer of film was spun off at a speed of 7000rpm for 2 minutes, and the film thickness was about 11-15 nm; the second-third layer of film was spun off at a speed of 5000rpm for 2 1 minute, the film thickness is about 19-24nm, and the other layers of film are thrown at a speed of 6000rpm for 2 minutes to ensure that the film thickness is about 14-18nm;

[0048] 3. Heat treatment

[0049] With embodiment 1.

[0050] 4. Repeat the above steps 2 and 3 several ...

Embodiment 3

[0053] BiFeO 3 The preparation of thin film, steps are as follows:

[0054] 1. Configuration of precursor solution

[0055] With embodiment 1.

[0056] 2. Coating machine throwing film

[0057] (100) Nb:SrTiO 3 The substrate is placed in a tube furnace at 700 o C under heat treatment for 30 minutes, then keep the temperature at 80 o C and put it into a homogenizer, keep the humidity range at 14-17%, then apply the precursor solution on the substrate, and prepare a single-layer film by spin coating; wherein, the first layer of film is thrown at a speed of 6000rpm , the time is 2 minutes, the film thickness is about 14-18 nm; the 2-3 layer film is spun at a speed of 4000rpm, the time is 1 minute, the film thickness is about 22-26nm, and the other layers are spun at a speed of 5000rpm , the time is 1 minute, and the film thickness is guaranteed to be around 19-24;

[0058] 3. Heat treatment

[0059] With embodiment 1.

[0060] 4. Repeat the above steps 2 and 3 several ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com