Device and method for preparing carbon black by plasma countercurrent cracking of gaseous hydrocarbon

A plasma and gaseous hydrocarbon technology, applied in the direction of plasma, electrical components, fibrous fillers, etc., can solve the problems of low mixing efficiency of raw gas and plasma arc, short continuous operation time, etc., to reduce processing costs and improve mixing efficiency , Guarantee the effect of variety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

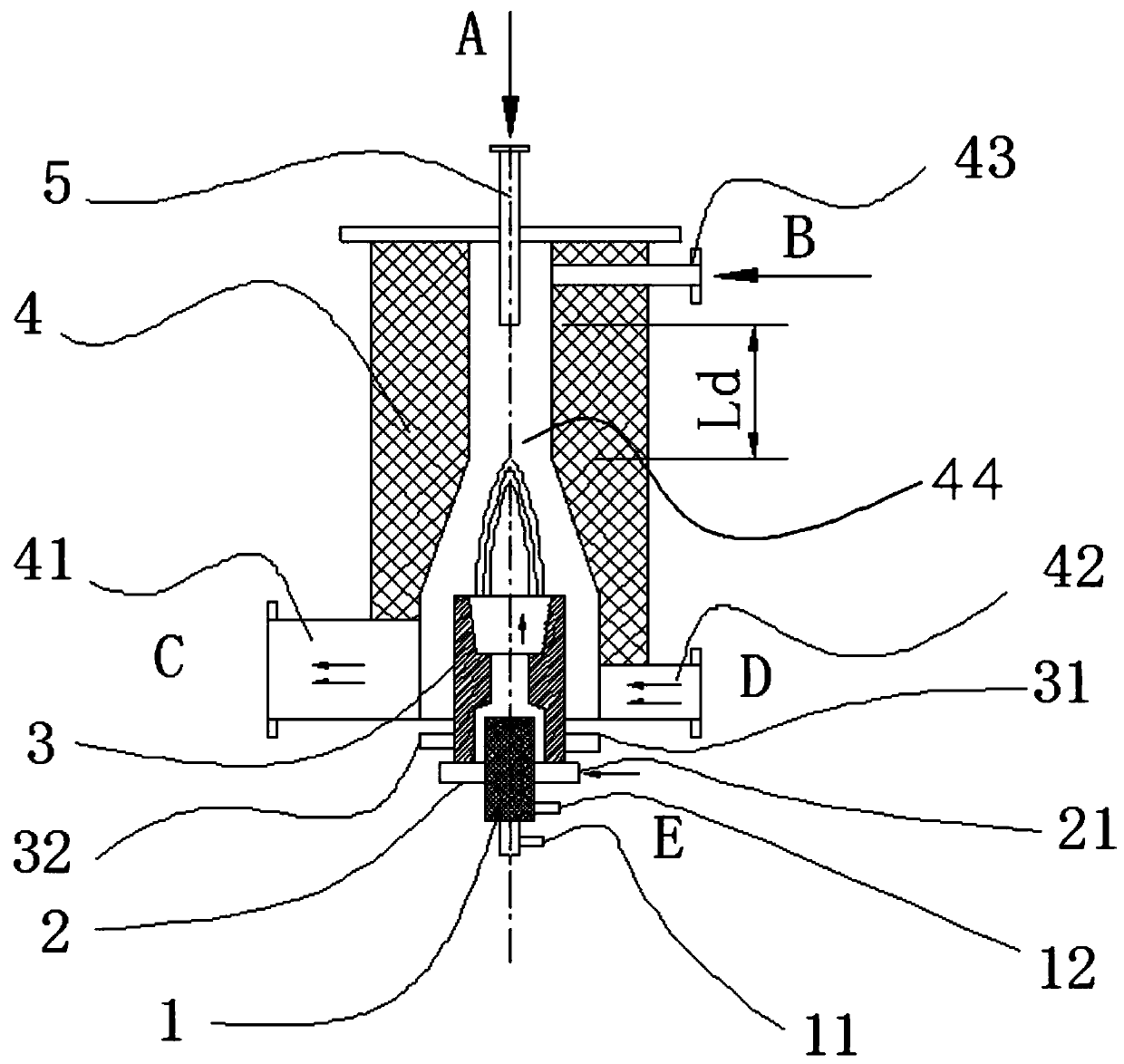

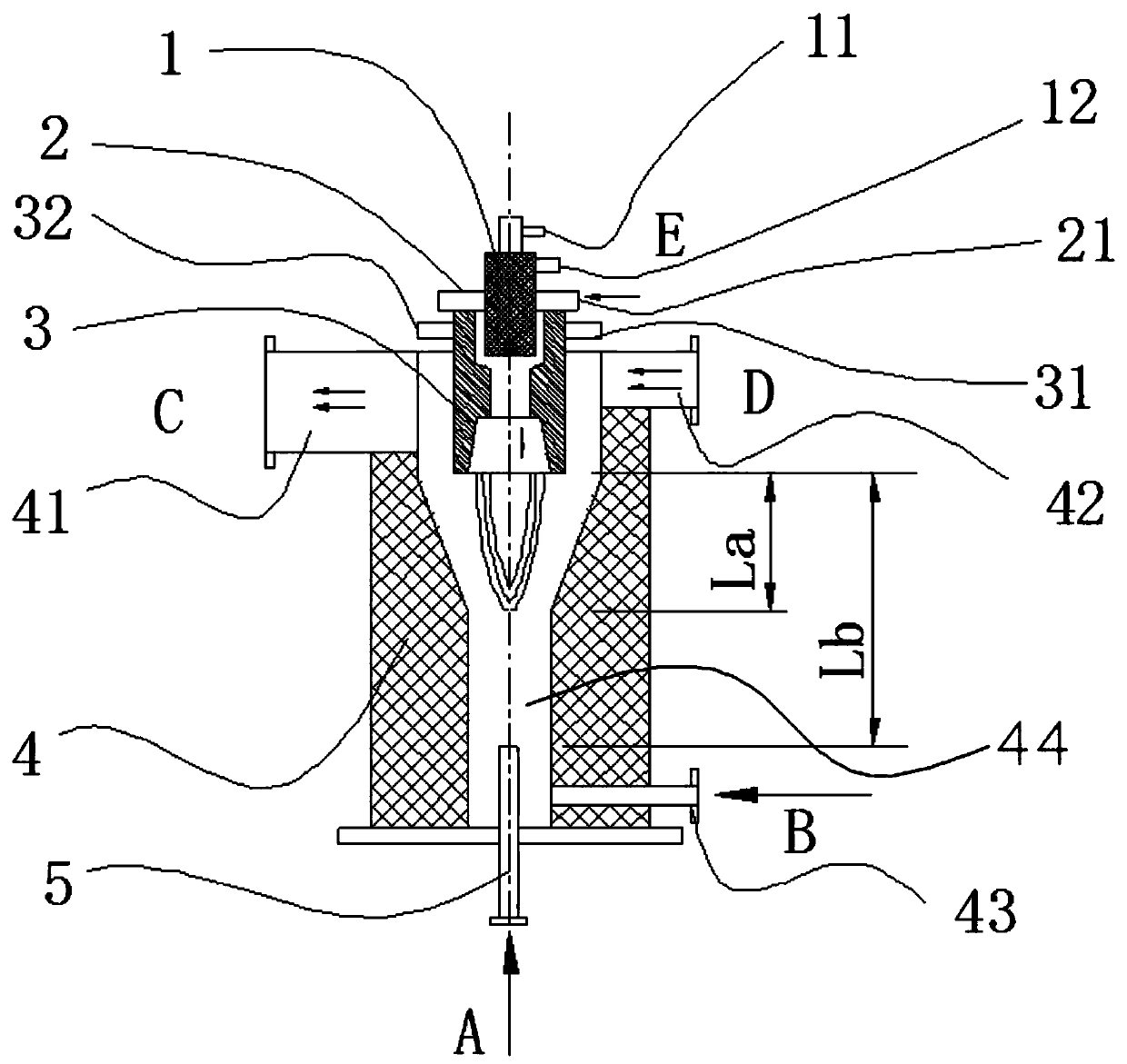

[0041] like figure 1 and figure 2As shown, a kind of equipment for preparing carbon black by plasma countercurrent cracking of gaseous hydrocarbons includes a columnar reactor body 4 with a cylindrical reaction chamber 44 inside, and an annular anode 3 is provided at one end of the reactor body 4. One end of the anode 3 extends into the reaction chamber 44, and the other end of the anode 3 is sleeved with a columnar cathode 1, and the cathode 1 is connected to the anode 3 through an insulator 2; The other end is provided with a raw material gas inlet pipe 5, and one end of the raw material gas inlet pipe 5 extends into the reaction chamber 44, and the central axis where the raw material gas inlet pipe 5 is located coincides with the central axis where the anode 3 is located; The insulator 2 is provided with a plasma working gas inlet 21 connected to the inner ring of the anode 3, and the side of the reactor body 4 is provided with an auxiliary gas inlet 43 near the raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com