Crosslinking agent for polyacrylamide water plugging agent, and preparation method and application of crosslinking agent

A technology of polyacrylamide and cross-linking agent is applied in the field of cross-linking agent of polyacrylamide water blocking agent, which can solve the problems of fast gel formation, easy precipitation, poor viscoelasticity, etc. Coagulation phenomenon, good injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a cross-linking agent of polyacrylamide water blocking agent, comprising the following steps:

[0025] S1, adding deionized water, chromium nicotinate complex, aluminum citrate, sodium carboxymethylcellulose and organic acid into the stirring reactor in sequence, and stirring and reacting at 80°C to 90°C for 6h to 9h; and

[0026] S2, adding an acidity regulator to the mixed solution after the stirring reaction in S1 to adjust to alkalinity to obtain a crosslinking agent product.

[0027] In S2, an acidity regulator is used to adjust the pH of the mixture to 7-8.

[0028] An application of the cross-linking agent in polyacrylamide water blocking agent, the mass ratio of the cross-linking agent to the polyacrylamide is 3-6:7-12.

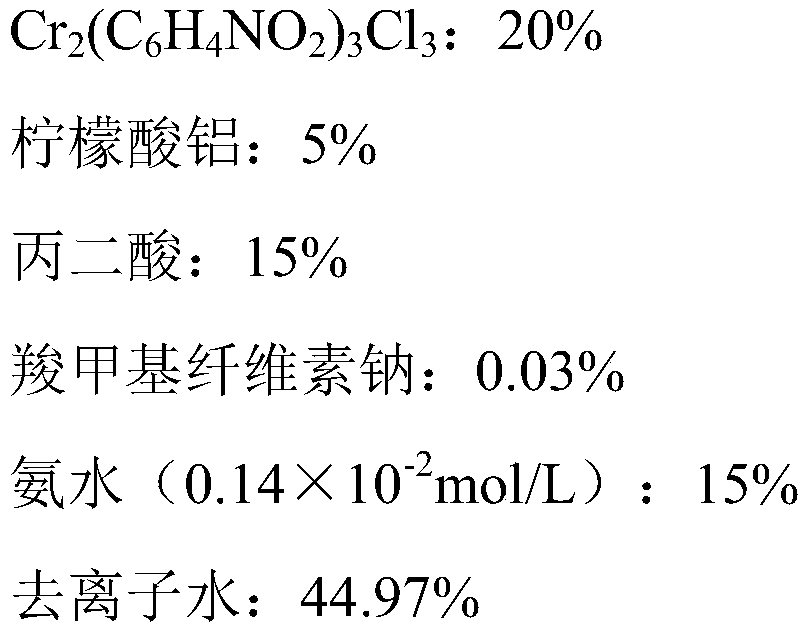

Embodiment 1

[0030] Select raw materials by weight percentage

[0031]

[0032] Concrete preparation steps are:

[0033] (1) Deionized water, Cr 2 (C 6 h 4 NO 2 ) 3 Cl 3 , aluminum citrate, sodium carboxymethylcellulose, and malonic acid were sequentially added into the stirred reactor, and stirred and reacted at 80°C for 6h.

[0034] (2) Add ammonia water to the mixed solution after the stirring reaction in step (1), and adjust to 7 to obtain a crosslinking agent product.

[0035] Preparation of water blocking agent: select polyacrylamide with a molecular weight of 14 million (Japan Sanyo Chemical Company, industrial grade), take 4.5g of the above-mentioned polyacrylamide, add it to 1000mL water, stir to dissolve, and then add 1.6g of cross-linking agent to fully Stir to make a weak gel.

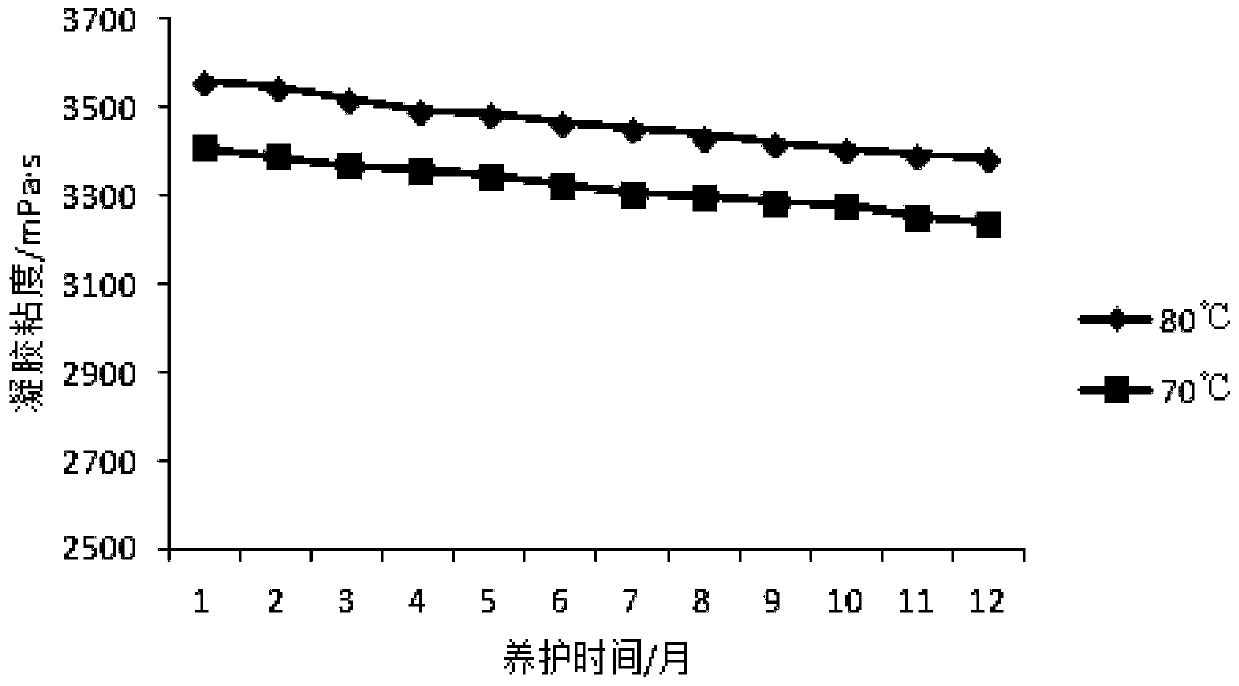

[0036] See Table 1 and Table 2 for the viscosity retention rate and gelation time of the weak gel. For storage stability of weak gels see figure 1 . Depend on figure 1 It can be seen that...

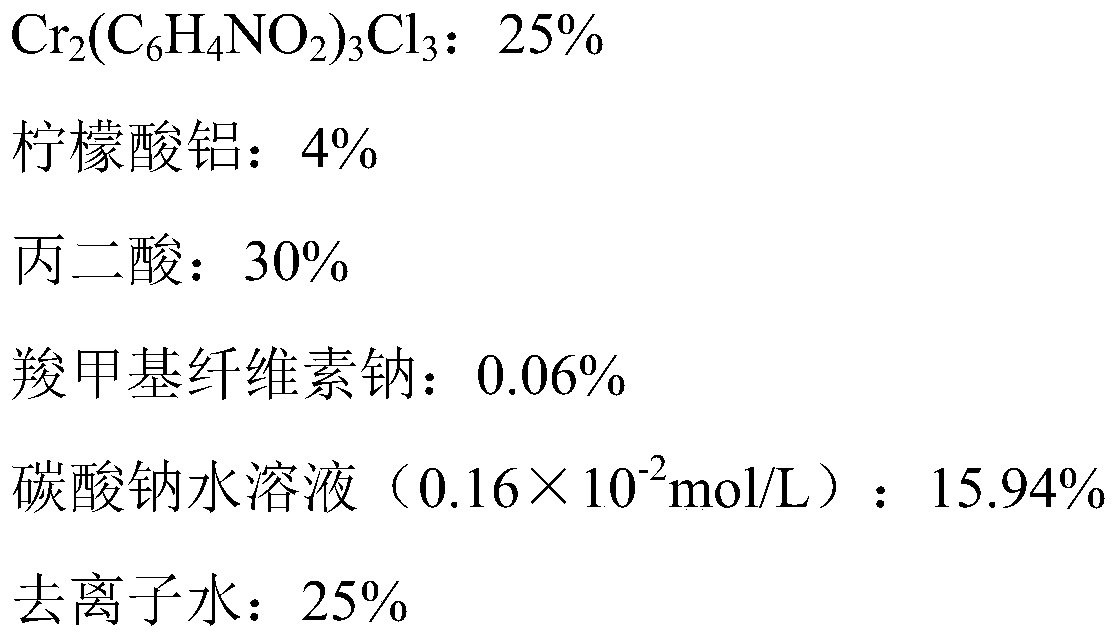

Embodiment 2

[0038] Select raw materials by weight percentage

[0039]

[0040] Concrete preparation steps are:

[0041] (1) Deionized water, Cr 2 (C 6 h 4 NO 2 ) 3 Cl 3 , aluminum citrate, sodium carboxymethylcellulose, and malonic acid were sequentially added into the stirred reactor, and stirred and reacted at 90°C for 9h.

[0042] (2) Add sodium carbonate aqueous solution to the mixed solution after the stirring reaction in step (1), and adjust to 8 to obtain a crosslinking agent product.

[0043]Preparation of water blocking agent: same as Example 1.

[0044] See Table 1 and Table 2 for the viscosity retention rate and gelation time of the weak gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com