Rare earth element high-entropy alloy material and preparing method thereof

A high-entropy alloy and rare earth element technology, applied in the field of materials, can solve problems such as staying in the initial stage, and achieve the effect of simple operation and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

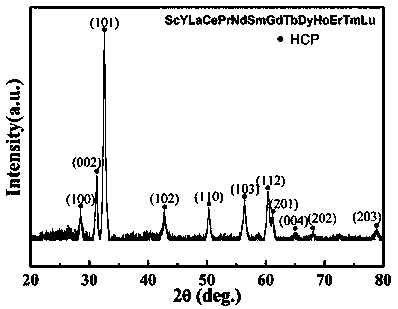

[0029] This implementation adopts the arc melting process to manufacture ScYLaCePrNdSmGdTbDyHoErTmLu high-entropy alloy materials according to the following steps:

[0030] (1) Weigh 14 kinds of rare earth element raw materials according to the equiatomic ratio.

[0031] (2) Put the raw materials of each element in the order of melting point from low to high (Ce, La, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Y, Er, Sc, Tm, Lu) into the copper of the arc melting furnace. molded crucible, and then evacuated to a vacuum degree lower than 1.5×10 -3 MPa, and then filled with argon gas with a purity of 99.9% to a pressure of 0.5 MPa in the non-consumable arc melting furnace.

[0032] (3) Arc smelting, the current is 150A during smelting, repeated smelting 5 times, and the melting furnace body should be cleaned immediately after each smelting. After the smelting is finished, there is no need for suction casting, and the rare earth element high-entropy alloy material can be obtained after the cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com