Chemical passivation process method for copper and copper alloy thin-walled part

A technology of chemical passivation and thin-walled parts, applied in the direction of metal material coating process, etc., can solve the problems of parts deformation, electropolishing treatment, and removal, etc., to improve the smoothness and chemical passivation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A chemical passivation process method for copper and copper alloy thin-walled parts, comprising the following steps: select a gasket part whose material is T2M, and after heat treatment, annealing and softening treatment, directly carry out chemical passivation treatment on the part with black oxide skin on the surface .

[0058] (1) acceptance;

[0059] (2) hanging;

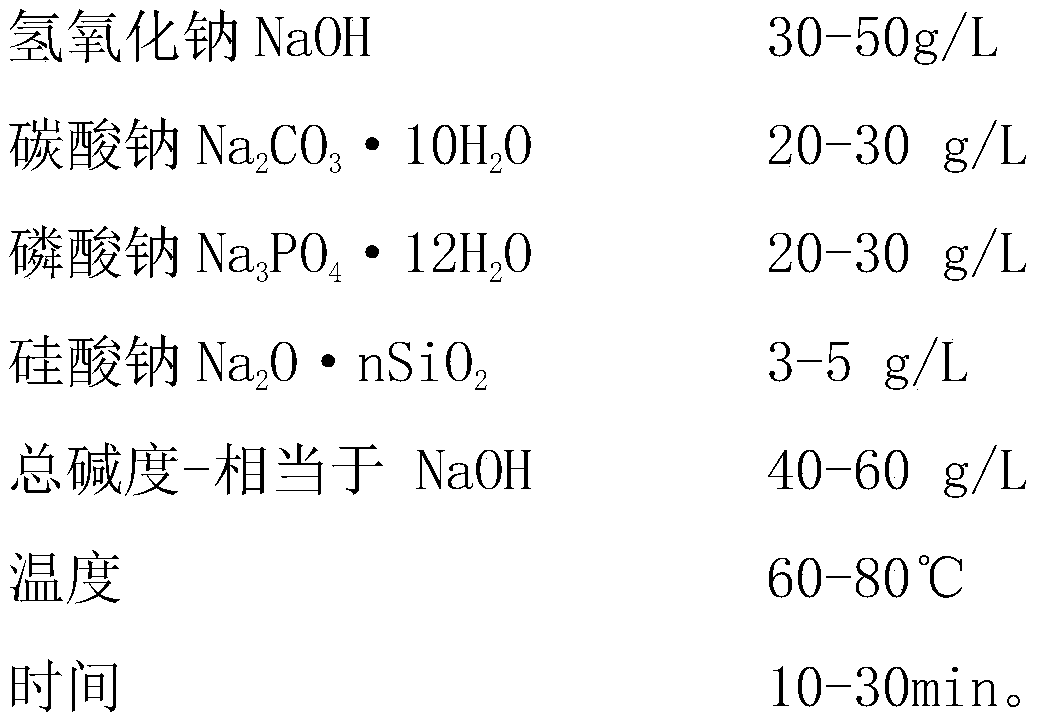

[0060] (3) Degreasing

[0061]

[0062] (4) hot water washing

[0063] Temperature 75°C;

[0064] Time 1min;

[0065] (5) Flowing cold water wash

[0066] time 120s;

[0067] (6) Check the continuity of the water film; the water film has not broken for 30 seconds;

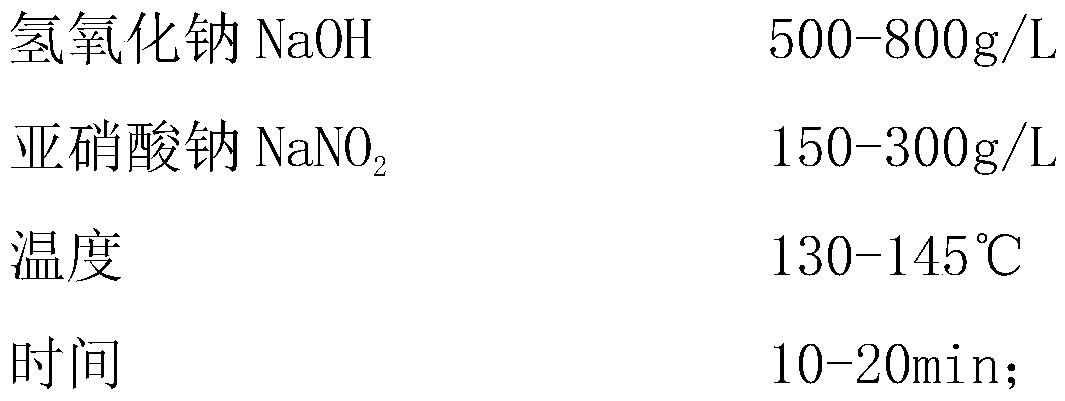

[0068] (7) Alkaline washing

[0069]

[0070]

[0071] (8) Flowing cold water wash

[0072] time 120s;

[0073] (9) Bright corrosion

[0074]

[0075] (10) Flowing cold water wash

[0076] time 120s;

[0077] (11) weak corrosion

[0078] Hydrochloric acid HCl 100-150g / L

[0079] temperature room temperature

[0080]...

Embodiment 2

[0093] A chemical passivation process method for copper and copper alloy thin-walled parts, comprising the following steps: select a gasket part whose material is T2M, and after heat treatment, annealing and softening treatment, directly carry out chemical passivation treatment on the part with black oxide skin on the surface .

[0094] (1) acceptance;

[0095] (2) hanging;

[0096] (3) Degreasing

[0097]

[0098] (4) hot water washing

[0099] Temperature 75°C

[0100] Time 1min;

[0101] (5) Flowing cold water wash

[0102] time 120s;

[0103] (6) Check the continuity of the water film; the water film has not broken for 30 seconds;

[0104] (7) Alkaline washing

[0105]

[0106]

[0107] (8) Flowing cold water wash

[0108] time 120s;

[0109] (9) Bright corrosion

[0110]

[0111] (10) Flowing cold water wash

[0112] Time 120s

[0113] (11) weak corrosion

[0114] Hydrochloric acid HCl 100-150g / L

[0115] temperature room temperature

[0116] T...

Embodiment 3

[0129] A chemical passivation process method for copper and copper alloy thin-walled parts, comprising the following steps: select a gasket part whose material is T2M, and after heat treatment, annealing and softening treatment, directly carry out chemical passivation treatment on the part with black oxide skin on the surface .

[0130] (1) acceptance;

[0131] (2) hanging;

[0132] (3) Degreasing

[0133]

[0134] (4) hot water washing

[0135] Temperature 75°C

[0136] Time 1min;

[0137] (5) Flowing cold water wash

[0138] time 120s;

[0139] (6) Check the continuity of the water film; the water film has not broken for 30 seconds;

[0140] (7) Alkaline washing

[0141]

[0142] (8) Flowing cold water wash

[0143] time 120s;

[0144] (9) Bright corrosion

[0145]

[0146] (10) Flowing cold water wash

[0147] time 120s;

[0148] (11) weak corrosion

[0149] Hydrochloric acid HCl 100-150g / L

[0150] temperature room temperature

[0151] Time 0.8min;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com