Preparing method of graphene thermoelectricity fibers with interphase types p and n

A graphene fiber, graphene technology, applied in the direction of carbon fiber, fiber processing, fiber chemical characteristics, etc., can solve the problems of poor flexibility, continuity and mechanical properties, unfavorable portable wearable device application, single and other problems, and achieve low preparation cost. , good flexibility, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

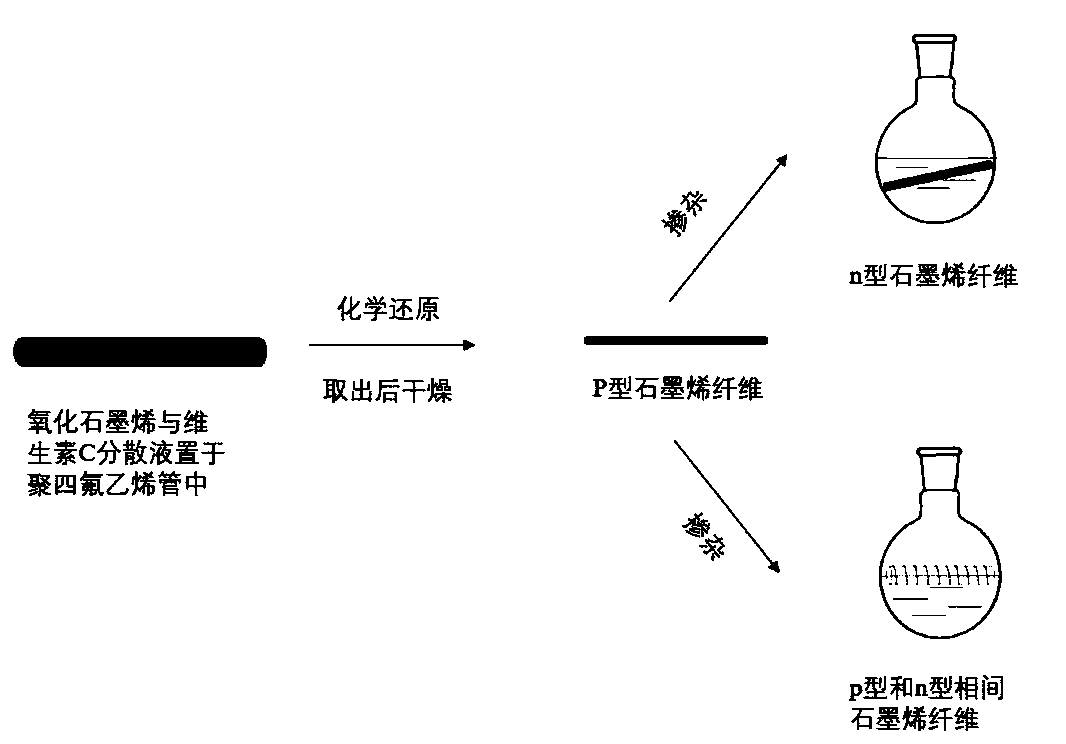

[0028] Such as figure 1 Shown, a kind of preparation method of the graphene thermoelectric fiber of p-type and n-type phase, comprises the following steps:

[0029] (1) graphite is prepared into graphene oxide dispersion liquid by modified Hummers method, wherein, the particle size of graphite is 200 orders, and the concentration of the graphene oxide dispersion liquid obtained is 6mg / ml;

[0030] (2) Take the above 2ml graphene oxide dispersion in a clean reagent bottle, add 0.03g of vitamin C to mix with it, shake fully, put the reagent bottle into an ultrasonic instrument and ultrasonically 10min to make the solution evenly dispersed, and then transfer the dispersion to In a polytetrafluoroethylene tube, place it in an oven and react at 60°C for 1 hour to obtain graphene fibers;

[0031] (3) the graphene fiber of step (2) gained is dried at room temperature 30min, then rolled on the foam, half soaked in the dopant solution polyethyleneimine aqueous solution, the concentrat...

Embodiment 2

[0039] A preparation method of a p-type and n-type interphase graphene thermoelectric fiber, comprising the following steps:

[0040] (1) graphite is prepared into graphene oxide dispersion liquid by modified Hummers method, wherein, the particle size of graphite is 200 orders, and the concentration of the graphene oxide dispersion liquid obtained is 6mg / ml;

[0041] (2) Take the above 2ml graphene oxide dispersion in a clean reagent bottle, add 0.06g of vitamin C to mix it, shake fully, put the reagent bottle into an ultrasonic instrument and ultrasonically 10min to make the solution evenly dispersed, and then transfer the dispersion to In a polytetrafluoroethylene tube, place it in an oven and react for 2 hours at 80°C to obtain graphene fibers;

[0042] (3) The graphene fiber obtained in step (2) is dried at room temperature for 30min, then rolled on the foam, and half of it is soaked in the dopant solution polyethoxyethyleneimine aqueous solution, and the concentration of ...

Embodiment 3

[0045] A preparation method of a p-type and n-type interphase graphene thermoelectric fiber, comprising the following steps:

[0046] (1) graphite is prepared into graphene oxide dispersion liquid by modified Hummers method, wherein, the particle size of graphite is 200 orders, and the concentration of the graphene oxide dispersion liquid obtained is 6mg / ml;

[0047] (2) Take the above 2ml graphene oxide dispersion in a clean reagent bottle, add 0.04g of vitamin C to mix it, shake it fully, put the reagent bottle into an ultrasonic instrument and ultrasonically for 10min to make the solution evenly dispersed, and then transfer the dispersion to In a polytetrafluoroethylene tube, place it in an oven and react for 1 hour at 80°C to obtain graphene fibers;

[0048](3) Dry the graphene fiber obtained in step (2) at room temperature for 30 minutes, then roll it on the foam, and half soak it in the dopant solution, the dopant solution is polyethyleneimine aqueous solution and polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com