SMT surface mounting process

A patch and process technology, applied in the direction of epoxy resin glue, adhesive type, adhesive additives, etc., can solve the problems of slow curing speed, complex process, low product qualification rate, etc., to improve production efficiency, bonding The effect of high strength and fast packaging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of SMT patch technology, comprises the steps:

[0025] (1) Pretreatment: cleaning and drying the PCB board;

[0026] (2) Glue dispensing: use a glue dispenser to apply patch glue to the preset glue dispensing position on the PCB;

[0027] (3) SMT: use a SMT machine to mount the components on the PCB;

[0028] (4) Curing: Send the PCB board into the curing equipment and cure it at 130°C for 2 minutes;

[0029] (5) Reflow soldering: send the PCB board into the reflow soldering furnace for reflow soldering;

[0030] (6) Inspection: check the yield rate of the finished product.

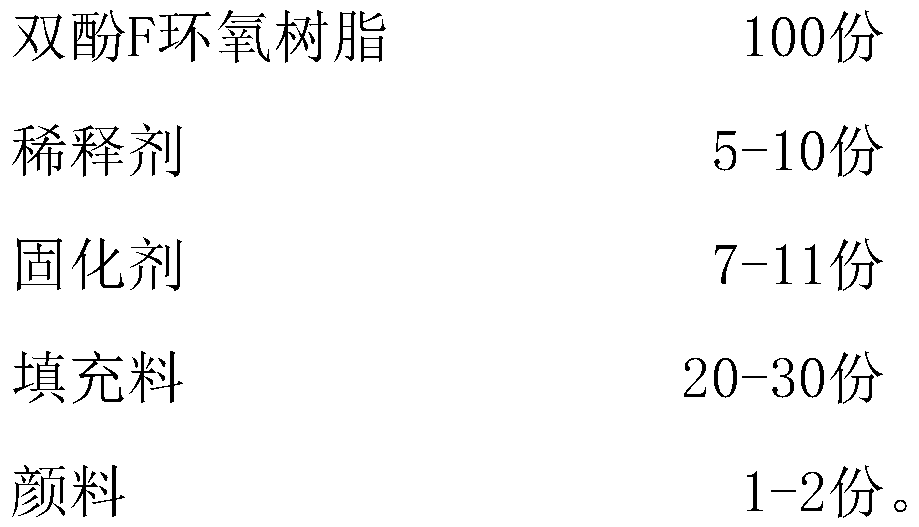

[0031] Wherein, the patch glue includes the raw materials of the following parts by weight:

[0032]

[0033]

[0034] Wherein, the bisphenol F epoxy resin is EPON862.

[0035] Wherein, the diluent is HELOXY8.

[0036] Wherein, the curing agent is composed of EH-4070S and PN23 in a weight ratio of 3:1.

[0037] Wherein, the filler is prepared by ultrasonically dispersing microcr...

Embodiment 2

[0041] A kind of SMT patch technology, comprises the steps:

[0042] (1) Pretreatment: cleaning and drying the PCB board;

[0043] (2) Glue dispensing: use a glue dispenser to apply patch glue to the preset glue dispensing position on the PCB;

[0044] (3) SMT: use a SMT machine to mount the components on the PCB;

[0045] (4) Curing: Send the PCB board into the curing equipment and cure it at 120°C for 2 minutes;

[0046] (5) Reflow soldering: send the PCB board into the reflow soldering furnace for reflow soldering;

[0047] (6) Inspection: check the yield rate of the finished product.

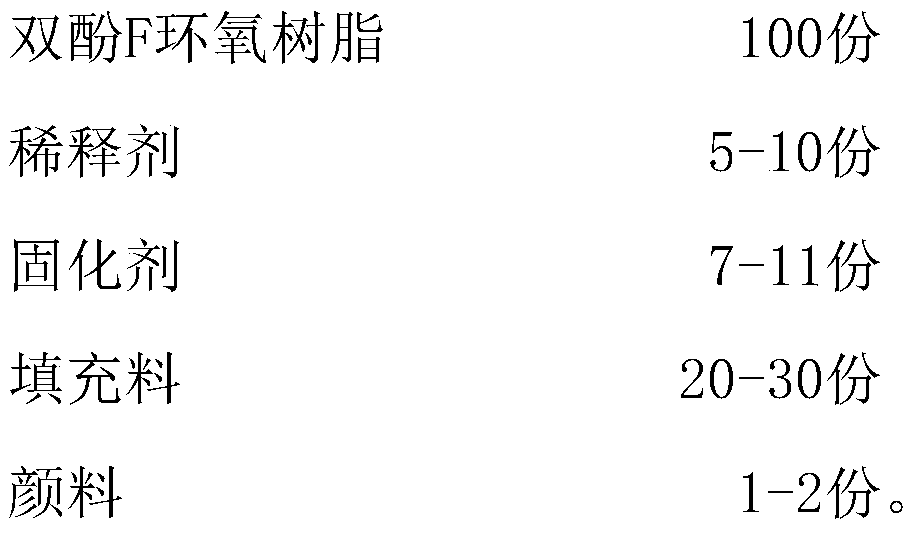

[0048] Wherein, the patch glue includes the raw materials of the following parts by weight:

[0049]

[0050] Wherein, the bisphenol F epoxy resin is EPON862.

[0051] Wherein, the diluent is HELOXY8.

[0052] Wherein, the curing agent is composed of EH-4070S and PN23 in a weight ratio of 5:1.

[0053] Wherein, the filler is prepared by ultrasonically dispersing microcrystalline ce...

Embodiment 3

[0057] A kind of SMT patch technology, comprises the steps:

[0058] (1) Pretreatment: cleaning and drying the PCB board;

[0059] (2) Glue dispensing: use a glue dispenser to apply patch glue to the preset glue dispensing position on the PCB;

[0060] (3) SMT: use a SMT machine to mount the components on the PCB;

[0061] (4) Curing: send the PCB board into the curing equipment, and cure at 110°C for 1 min;

[0062] (5) Reflow soldering: send the PCB board into the reflow soldering furnace for reflow soldering;

[0063] (6) Inspection: check the yield rate of the finished product.

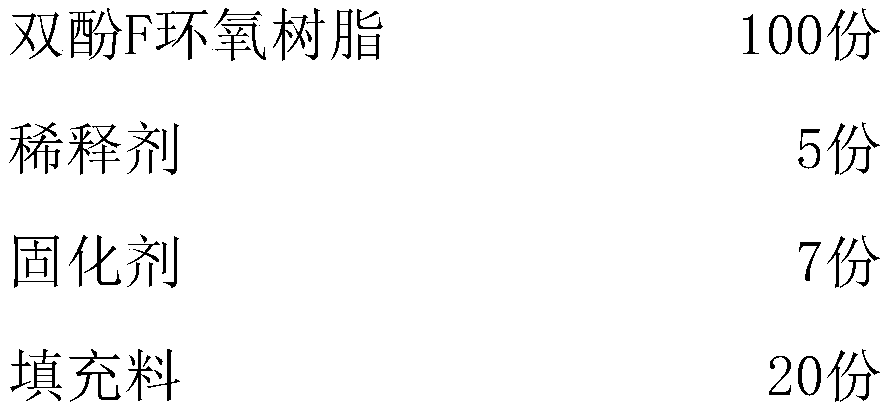

[0064] Wherein, the patch glue includes the raw materials of the following parts by weight:

[0065]

[0066]Wherein, the bisphenol F epoxy resin is EPON862.

[0067] Wherein, the diluent is HELOXY8.

[0068] Wherein, the curing agent is composed of EH-4070S and PN23 in a weight ratio of 4:1.

[0069] Wherein, the filler is prepared by ultrasonically dispersing microcrystalline cellulose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com