Purification method of heavy metals in humic acid liquid fertilizer

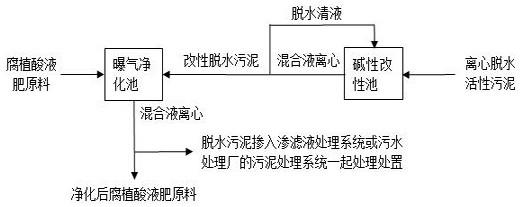

A humic acid and heavy metal technology, which is applied in chemical instruments and methods, organic fertilizers, contaminated groundwater/leachate treatment, etc., can solve the problem of limited research and development of heavy metal purification methods and applicable technologies, lack of mature extraction technologies, and insufficient application. problem, to achieve the effect of stable system operation, simple process system operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The following is an example of the purification of heavy metals in the semi-finished product containing humic acid water-soluble fertilizer raw materials extracted by the MBR+NF concentrate of a domestic waste landfill and incineration power plant mixed leachate treatment plant, further illustrating the present invention.

[0020] The leachate of the domestic waste leachate treatment plant is the mixed leachate of landfill and incineration plant, which produces 1,500 tons of leachate per day. It adopts water quality balance as the pretreatment process, MBR as the main biochemical treatment process, and NF as the advanced treatment process flow. The treatment plant produces about 300 tons of MBR+NF concentrate per day, and can extract about 7.5 tons of humic acid-containing water-soluble fertilizer raw materials per day. The humic acid liquid fertilizer raw material has a humic acid content of 41g / L, of which fulvic acid is 34.6g / L, and the pH value is 7.1. The types wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com