Light microporous ceramsite sand and preparation process thereof

A preparation process and technology of ceramsite sand, which is applied in the field of proppant to achieve the effect of improving screening effect, wide application range and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

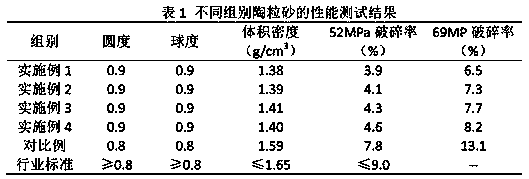

Embodiment 1

[0028] Embodiment 1: This embodiment provides a light microporous ceramsite sand and its preparation process. The raw materials used in the preparation include 35 parts of coal gangue, 50 parts of coke gems, 5 parts of dolomite, 25 parts of purple sand slag, and 8 parts of spinel. parts, 10 parts of perlite, 10 parts of silica fume; among them, Al in burnt gem 2 o 3 The content is 37.8%, SiO 2 The content is 42.3%; CaCO in dolomite 3 The content is 30.4%, MgCO 3 The content is 23.9%.

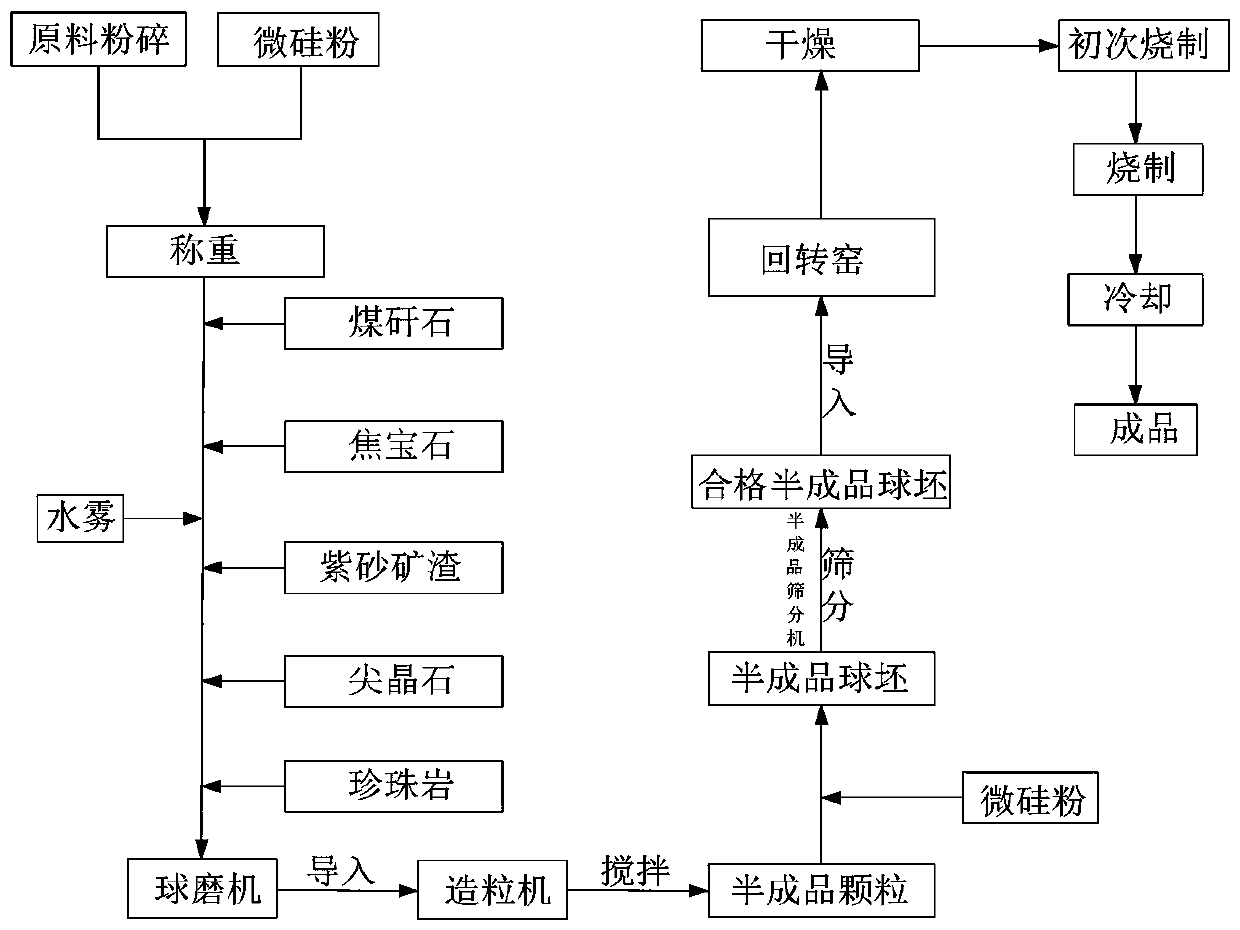

[0029] Preparation process: the specific process is as follows figure 1 shown;

[0030] Step 1, pulverizing coal gangue, coke gemstone, dolomite, purple sand slag, spinel and perlite respectively, pouring them into a ball mill to grind to obtain mixture powder, and passing the mixture powder through a 325-400 mesh sieve;

[0031] Step 2. Add the mixed coal gangue, coke gemstone, dolomite, purple sand slag, spinel and perlite into the granulator for stirring. During the stirring process, s...

Embodiment 2

[0037] Embodiment 2: the lightweight microporous ceramsite sand of the present embodiment, the raw materials used are the same batch as the raw materials used in embodiment 1, and the difference from embodiment 1 is that the raw materials used include 45 parts of coal gangue and 40 parts of coke gemstones, 5 parts of dolomite, 25 parts of purple sand slag, 8 parts of spinel, 10 parts of perlite, and 10 parts of microsilica.

Embodiment 3

[0038] Embodiment 3: the lightweight microporous ceramsite sand of the present embodiment, the raw materials used are the same batch as the raw materials used in embodiment 1, and the difference from embodiment 1 is that the raw materials used include 30 parts of coal gangue and 60 parts of coke gemstones, 6 parts of dolomite, 20 parts of purple sand slag, 10 parts of spinel, 5 parts of perlite, 7 parts of silica fume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com