Soil water-retaining agent for saline-alkali soil and preparation method

A soil water-retaining agent and a technology for saline-alkali land, applied in the field of soil drought-resistant materials, can solve problems such as poor saline-alkali resistance and inapplicability, and achieve the effects of improving alkali resistance, water absorption capacity, and high liquid absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

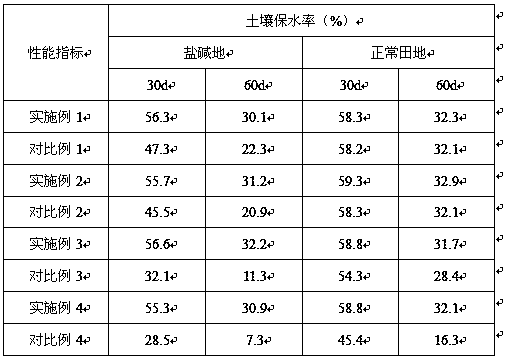

Examples

Embodiment 1

[0034] (1) First, the kaolin ore is crushed and ground, then purified to remove impurities, then mixed with N,N-dimethylacrylamide monomer solution, and then mechanically stirred for 23 hours at room temperature at a speed of 170 rpm, using N,N- Dimethacrylamide is directly intercalated with kaolin, and filtered to obtain N,N-dimethylacrylamide intercalated kaolin; in the preparation of N,N-dimethylacrylamide intercalated kaolin, N,N-dimethylacrylamide The mass ratio of acrylamide and kaolin is 100:12;

[0035] (2) First, mix acrylic acid and starch evenly, add water to control the temperature of the material to be 85 °C, and keep heat for 1.5 hours to gelatinize the starch to obtain a gelatinized product; the starch is corn starch; the mass ratio of acrylic acid, corn starch and water is 2:1:5;

[0036] (3) Transfer the gelatinized product into the reaction kettle, first introduce nitrogen gas, then add dextrin, straw powder, corn husk, diatomaceous earth, initiator and cros...

Embodiment 2

[0042] (1) First, the kaolin ore is crushed and ground, then purified to remove impurities, then mixed with N,N-dimethylacrylamide monomer solution, and then mechanically stirred for 25h at a speed of 150rpm under normal temperature conditions, using N,N- Dimethacrylamide is directly intercalated with kaolin, and filtered to obtain N,N-dimethylacrylamide intercalated kaolin; in the preparation of N,N-dimethylacrylamide intercalated kaolin, N,N-dimethylacrylamide The mass ratio of acrylamide and kaolin is 100:5;

[0043] (2) First, mix acrylic acid and starch evenly, add water to control the temperature of the material to be 85 °C, and keep heat for 1.5 hours to gelatinize the starch to obtain a gelatinized product; the starch is corn starch; the mass ratio of acrylic acid, corn starch and water is 2:1:5;

[0044] (3) Transfer the gelatinized product into the reaction kettle, first introduce nitrogen gas, then add dextrin, straw powder, corn husk, diatomaceous earth, initiator...

Embodiment 3

[0049] (1) First, the kaolin ore is crushed and ground, then purified to remove impurities, then mixed with N,N-dimethylacrylamide monomer solution, and then mechanically stirred at a speed of 200rpm for 20h under normal temperature conditions, using N,N- Dimethacrylamide is directly intercalated with kaolin, and filtered to obtain N,N-dimethylacrylamide intercalated kaolin; in the preparation of N,N-dimethylacrylamide intercalated kaolin, N,N-dimethylacrylamide The mass ratio of acrylamide and kaolin is 100:20;

[0050] (2) First, mix acrylic acid and starch evenly, add water to control the temperature of the material to be 85 °C, and keep heat for 1.5 hours to gelatinize the starch to obtain a gelatinized product; the starch is corn starch; the mass ratio of acrylic acid, corn starch and water is 2:1:5;

[0051] (3) Transfer the gelatinized product into the reaction kettle, first introduce nitrogen gas, then add dextrin, straw powder, corn husk, diatomaceous earth, initiato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com