Method for preparing carbon nanotube film by printing method

A technology of carbon nanotube film and carbon nanotube, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of inapplicable large-area processing technology, inability to ensure uniformity, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the drawings and examples.

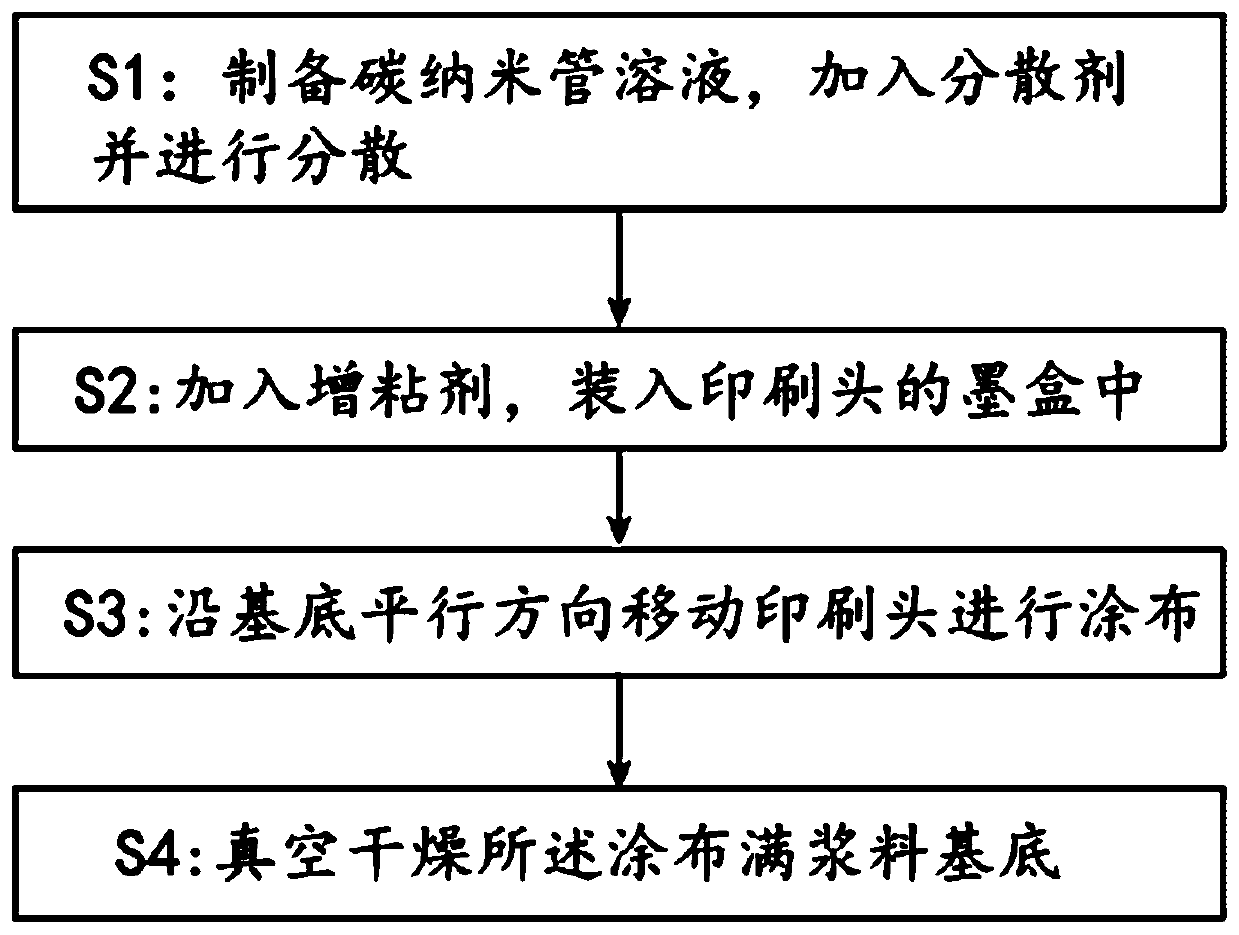

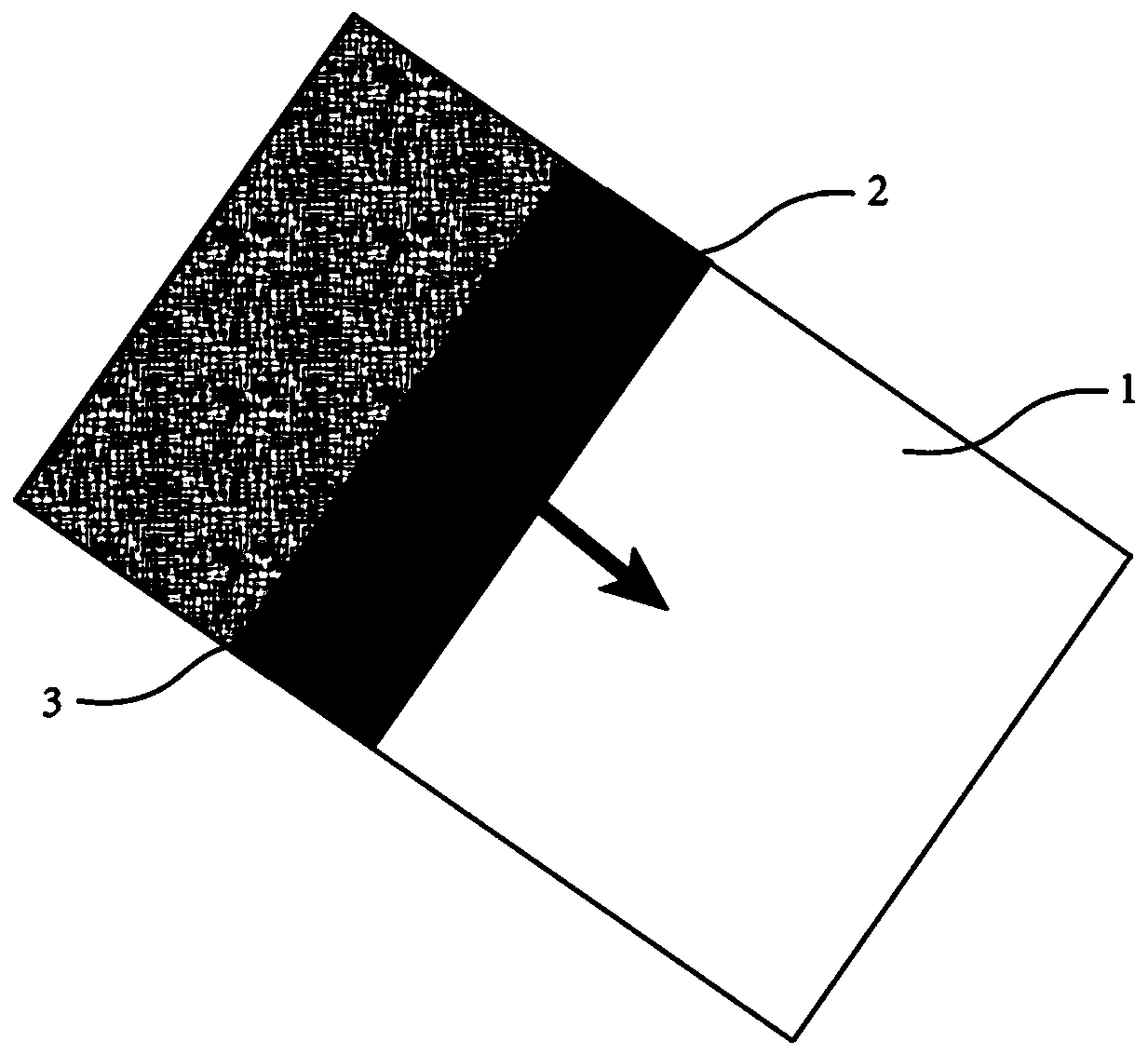

[0031] figure 1 The flowchart showing the carbon nanotube thin film preparation process of the present invention is based on the following figure 1 The flow chart shown and figure 2 The shown structural diagram of the device for the preparation of the carbon nanotube thin film describes in detail the specific embodiments of the present invention.

[0032] Such as figure 1 As shown, firstly, according to step S1, a carbon nanotube solution is prepared, and the carbon nanotubes are dissolved in one or more halogenated hydrocarbons, preferably chloroform, dichloroethane, trichloroethane, chlorobenzene, dichloro Benzene, bromobenzene and other organic solvents. The carbon nanotubes are selected from single-walled carbon nanotubes, double-walled carbon nanotubes or multi-walled carbon nanotubes, and of course, two or more of them can be selected withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com