Low-temperature sintered zinc oxide piezoresistor ceramic material, preparation method thereof, and preparation method of resistor

A varistor, low-temperature sintering technology, applied in varistor cores, varistors, resistors, etc., can solve the problems of bismuth oxide volatilization of formula materials, low product flow capacity, and inability to meet product use. , to achieve the effect of ensuring performance, extending service life and hindering migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

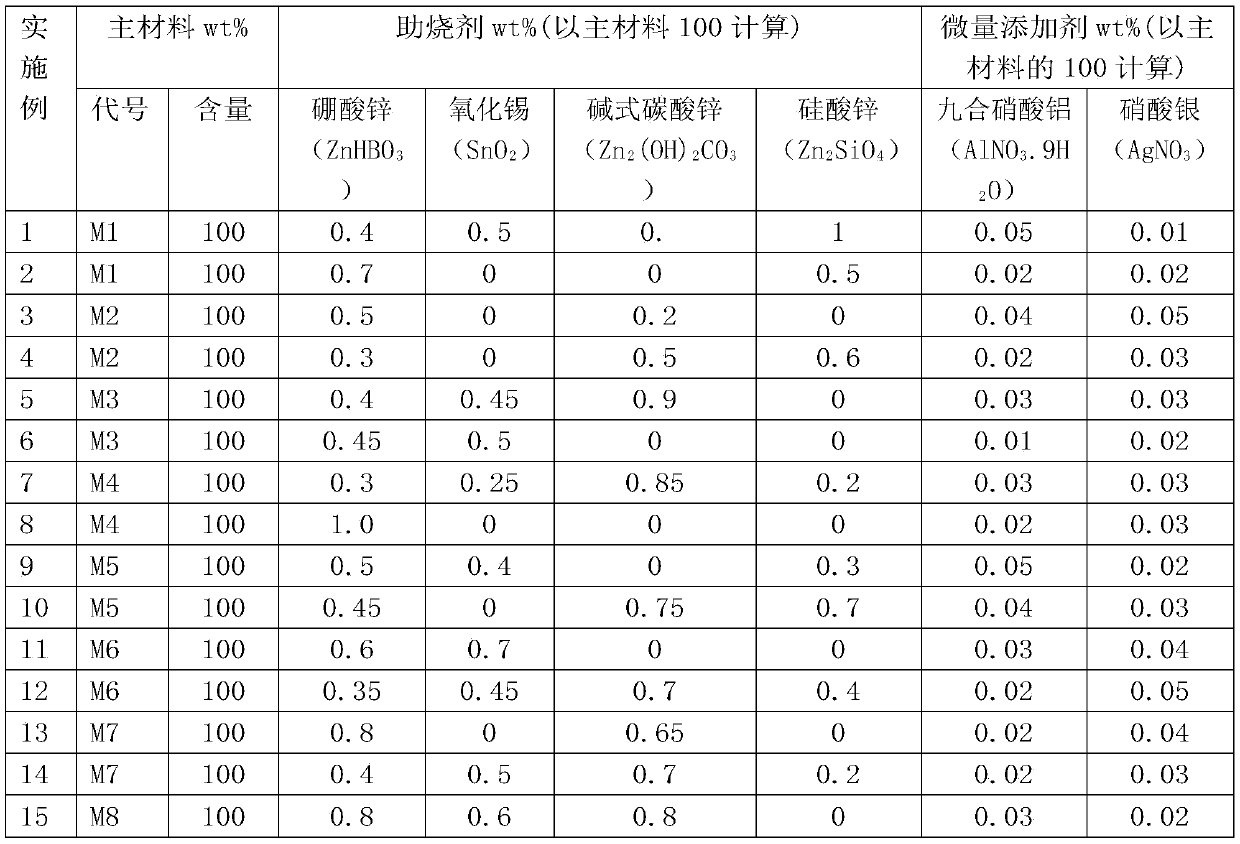

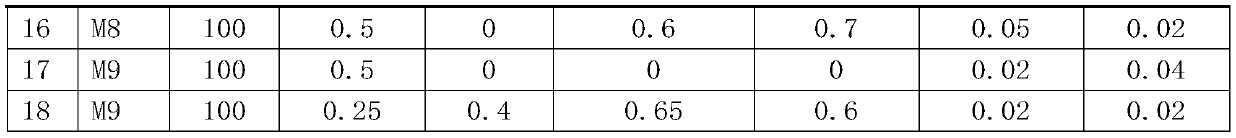

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below in conjunction with specific examples.

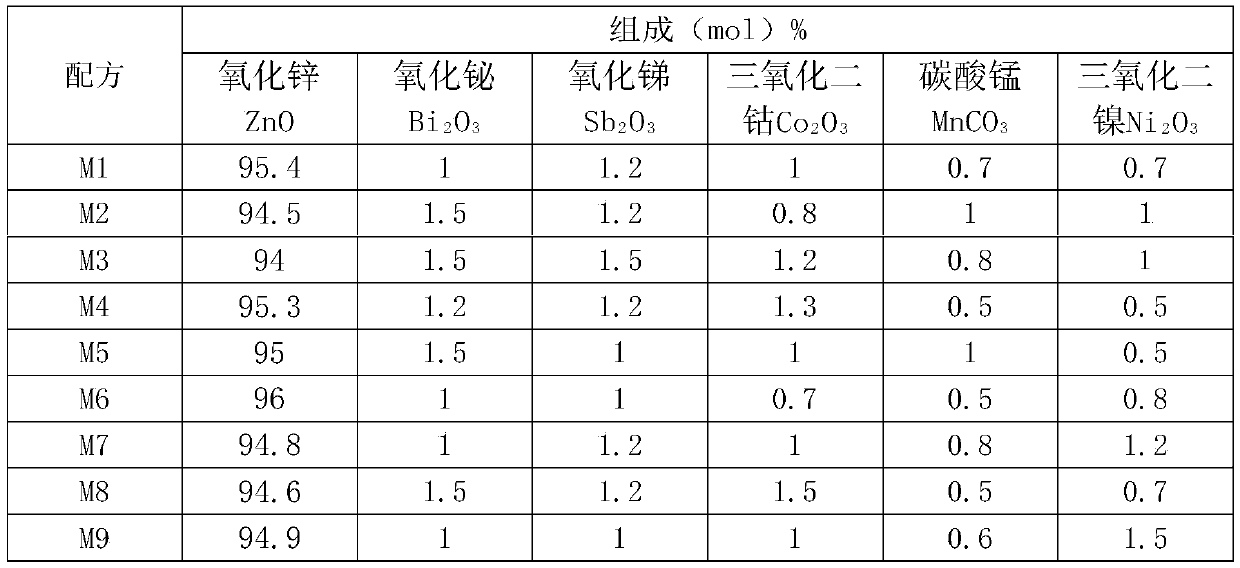

[0021] This embodiment discloses a low-temperature sintered zinc oxide varistor ceramic material, including main materials, sintering aids and trace additives. The main material is composed of the following molar percentage raw materials: zinc oxide (ZnO) ~ 96mol%, bismuth oxide (Bi 2 o 3 ) 1~1.5mol%, antimony oxide (Sb 2 o 3 )1~1.5mol%, cobalt trioxide (Co 2 o 3 )0.8~1.5mol%, manganese carbonate (MnCO 3 )0.7~1.0mol%, nickel trioxide (Ni 2 o 3 )0.5~1.5mol%. All of the above main materials can be obtained through direct purchase. The proportioning composition of the main materials can be shown in Table 1, and Table 1 lists the proportioning schemes of 9 implementations (M1-M9).

[0022] Table 1 Main materials of low-temperature sintered zinc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com