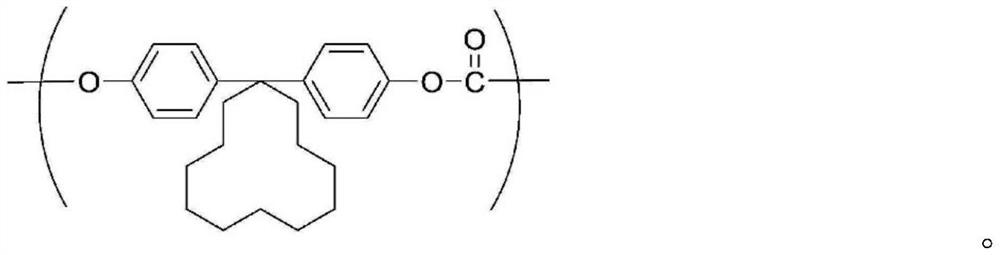

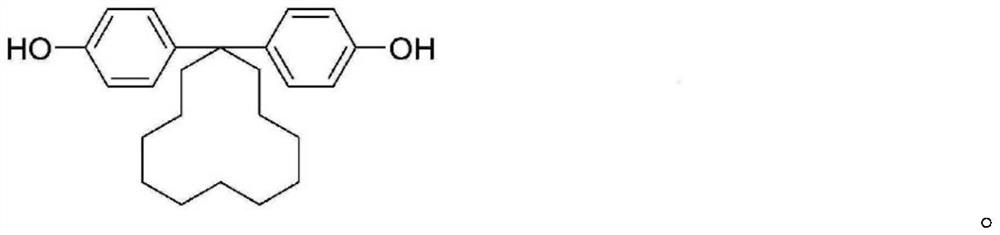

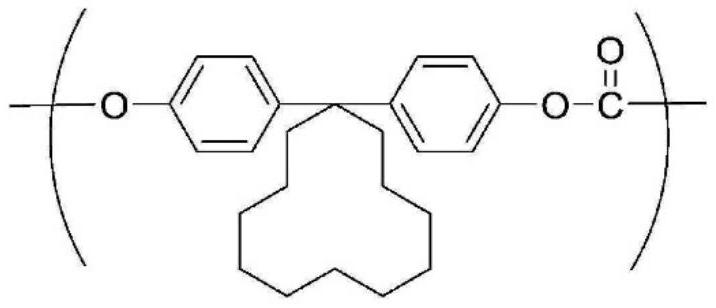

Aromatic polycarbonate oligomer solid

一种聚碳酸酯、寡聚体的技术,应用在芳香族聚碳酸酯寡聚体固体物领域,能够解决无提纯效果、装置腐蚀、难以分离等问题,达到保存稳定性优异、防止管线阻塞、提高生产性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited to these examples.

[0093] In addition, in the following examples, the weight average molecular weight was measured by gel permeation chromatography, the area % of low molecular weight components was measured by high performance liquid chromatography, and further loose bulk density was measured by the following method. Its analysis method is as follows.

[0094]

[0095] 1. Determination by Gel Permeation Chromatography

[0096] Device: HLC-8320GPC manufactured by Tosoh Corporation

[0097] Flow rate: 0.35ml / min, mobile phase: tetrahydrofuran, injection volume: 10μl

[0098] Chromatographic column: TSKgel guardcolumn SuperMP(HZ)-N, TSKgel SuperMultiporeHZ-N×3

[0099] Detector: RI, Analysis method: relative molecular weight in terms of polystyrene. polystyrene standard

[0100] A-500, A-2500, A-5000, F-1, F-2, and F-4 manufactured by Tos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loose density | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com