Separation medium, preparation method and applications thereof

A technology for separating medium and medium, applied in the field of separation medium and its preparation, can solve problems such as adverse effects on activity, and achieve the effects of low cost, high separation efficiency and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

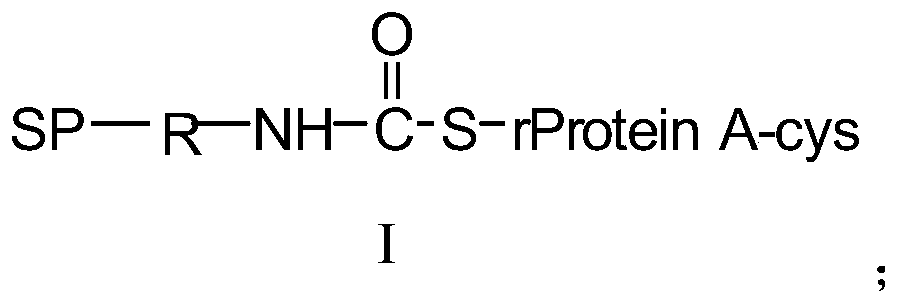

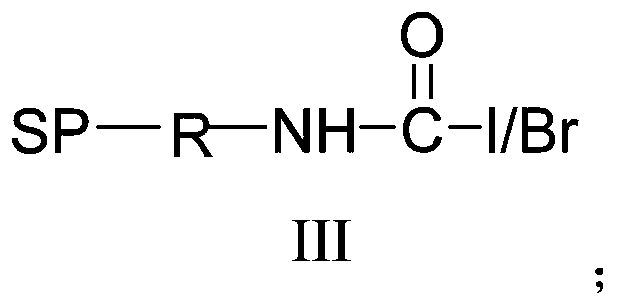

[0033] The present invention also provides a preparation method of separation medium, comprising the steps of:

[0034] S10, modifying amino groups on the surface of the base medium to obtain intermediate II,

[0035]

[0036] In one embodiment, the base medium is microspheres with epoxy groups or o-diol hydroxyl groups on the surface, and the microspheres are polymethacrylate microspheres, polyethylene-divinylbenzene microspheres or agarose microspheres.

[0037] In one embodiment, the modifying agent used to modify the amino group on the surface of the base medium is selected from the following organic amines: ethylenediamine, 1,3-propylenediamine, 1,6-hexamethylenediamine and 3,3'-diamine At least one of aminodipropylamine.

[0038] In one embodiment, in the obtained intermediate II, SP is the medium, and the medium is polymethacrylate microspheres, polyethylene-divinylbenzene microspheres or agarose microspheres.

[0039] When the above-mentioned organic amine is used...

Embodiment 1

[0061] The polymethacrylate microspheres used in this example (with a particle size of 30 μm, a pore size of 100 nm, and a large amount of epoxy groups on the surface); the manufacturer is Suzhou Saifen Technology Co., Ltd., and the rest of the raw materials are commercially available.

[0062] Weigh 100g of polymethacrylate microspheres, transfer to a 500mL three-neck flask, add 100g of 50wt% 3,3'-diaminodipropylamine aqueous solution, at room temperature, 100rpm mechanical stirring reaction for 16h, after the reaction is completed, use deionized water Filter and wash the microspheres to neutrality, then add 300mL 0.5M H 2 SO 4 The solution was reacted at 40° C. with mechanical stirring at 100 rpm for 4 hours. After the reaction, the microspheres were filtered and washed with deionized water until neutral.

[0063] The obtained microspheres were transferred to a 500mL three-necked flask, and 100mL of 0.1M 2-(N-morpholine)ethanesulfonic acid buffer solution (pH value 4.7) con...

Embodiment 2

[0068] The polymethacrylate microspheres used in this example (with a particle size of 30 μm, a pore size of 100 nm, and a large amount of o-diol hydroxyl groups on the surface); the manufacturer is Suzhou Saifen Technology Co., Ltd., and the rest of the raw materials are commercially available.

[0069] Weigh 100g of polymethacrylate microspheres, transfer to a 500mL three-neck flask, add 100mL0.2M NaIO 4 Solution, at room temperature, 100rpm mechanical stirring reaction for 1.5h, after the reaction is completed, use at least 10 times the volume of deionized water to filter and wash the medium, and then add 100mL of 0.1M phosphate buffer solution containing 1.52M 3,3'-diaminodipropylamine (pH value is 7.2), add 0.63g NaCNBH simultaneously 3 , at room temperature, 100rpm mechanical stirring reaction for 4h, after the reaction was completed, the microspheres were washed by suction filtration with at least 10 times the volume of deionized water.

[0070] The obtained microspher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com