A tailings treatment system

A processing system and tailings technology, applied in the direction of loading/unloading, mechanical conveyors, throwing machines, etc., can solve the problems of few dedicated, relying on preliminary treatment and sorting, slow conversion and utilization of tailings, etc., to achieve large load capacity, workload reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

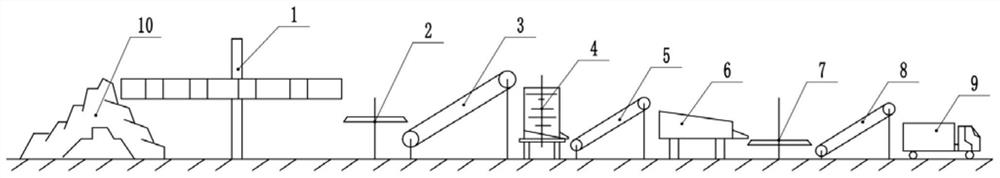

[0036] In a typical implementation of the present application, such as figure 1 As shown, a tailings treatment system is proposed.

[0037] It includes a picking device 1, a first distributor 2, a first conveying device 3, a crusher 4, a second conveying device 5, a material selection device 6, a second distributor 7 and a third conveying device 8 arranged in sequence, The tailings materials in the tailings pond 10 are processed and transported, and finally different grades and types of materials are output from the material selection device, and are transported to the transport vehicle 9 for different types of further processing and application.

[0038] The material pick-up device is a horizontal conveying device, which includes a bracket and a horizontally rotating belt installed on the bracket. Buckets are evenly distributed on the belt, and the buckets are driven by the belt to grab the material and horizontally transport it to the first On a feeder;

[0039] Change the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com