Method for preparing artificial vesuvianite from liquid refined manganese slag

A volcanic stone, artificial technology, applied in the field of metallurgy, can solve the problems of low utilization rate of slag bricks, low economic added value, etc., and achieve the effects of reducing reheating, saving energy, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

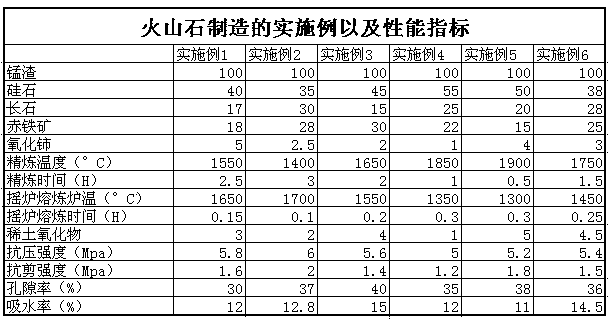

Examples

Embodiment Construction

[0023] The materials used in the technical solution will be described in detail below with reference to examples.

[0024] Silica is silicon dioxide, also known as quartz sand. It is used in the chemical industry to prepare silicon compounds and silicates. It can also be used as a filler for sulfuric acid towers. It can also be used in glass, ceramics, Portland cement, etc. in the building materials industry. It is used as raw material for smelting ferroalloys such as industrial silicon. Its chemical properties are very stable, insoluble in water and does not react with water. It does not react with common acids. At high temperature, silicon dioxide eutectically melts with alkaline oxides or certain metal carbonates to form silicates.

[0025] Alumina is a high-hardness compound with a melting point of 2054°C and a boiling point of 2980°C. It is an ionic crystal that can be ionized at high temperatures and is often used in the manufacture of refractory materials. There are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com