Method for preparing environment-friendly plasticizer from waste grease and application of method

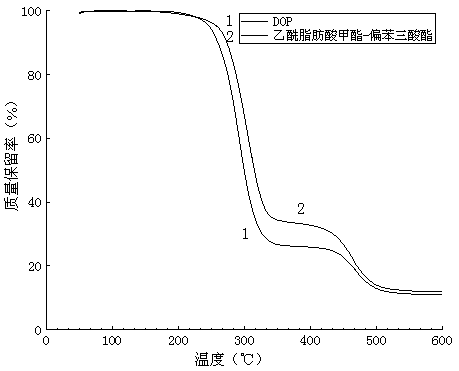

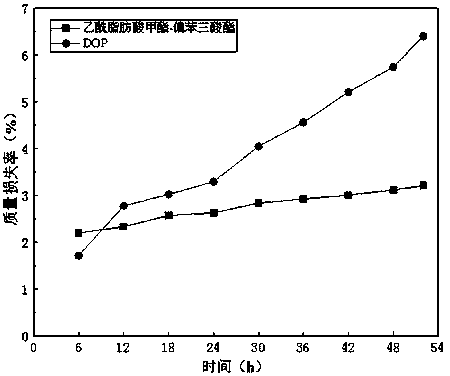

An environmentally friendly plasticizer and waste oil technology, which is applied in the preparation of carboxylate esters, chemical instruments and methods, and the preparation of organic compounds, can solve environmental pollution and other problems, and achieve good compatibility and excellent migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

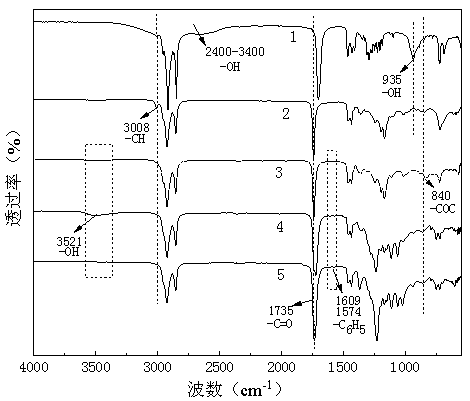

[0026] The preparation of embodiment 1 environmental protection plasticizer product acetyl fatty acid methyl ester-trimellitate

[0027] The reaction process is as follows:

[0028]

[0029] .

[0030] The specific steps are:

[0031] (1) Pretreatment of waste oil: first filter the waste oil at 10-30°C; then add activated clay for decolorization, the mass ratio of activated clay to oil is 1:20-40; add phosphoric acid and water For degumming, the mass of phosphoric acid added is 0.1% to 0.4% of the mass of the oil, and the mass of water added is 1% to 4% of the mass of the oil, and then washed with deionized water until neutral. Distill water under vacuum; then add methanol and sodium hydroxide solution for transesterification reaction, the molar ratio of oil and methanol is 1:3-8, the mass of sodium hydroxide is 0.3%-0.8% of the total mass, and the reaction temperature is 50~70℃, react for 4~8h, wash with deionized water until neutral, then distill under reduced pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com