2-amino-6-chloropurine as well as synthesis method, intermediate and application thereof

A synthetic method, the technology of chloropurine, which is applied in the field of medicine, can solve the problems of high equipment requirements, viscous materials, difficulty in suction filtration/centrifugation, etc., and achieve the effect of cheap and easy-to-obtain raw materials, few reaction steps, and good industrial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

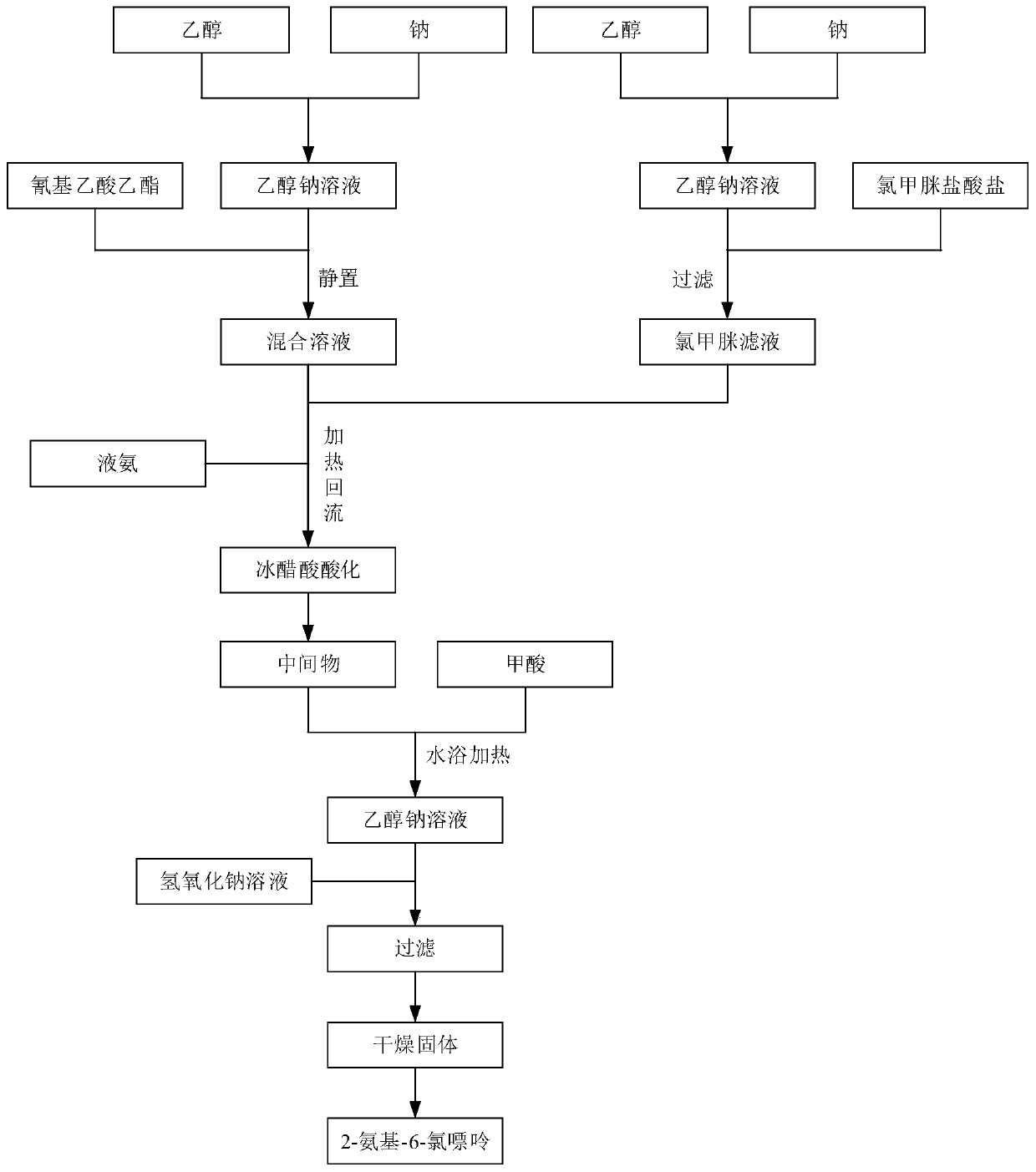

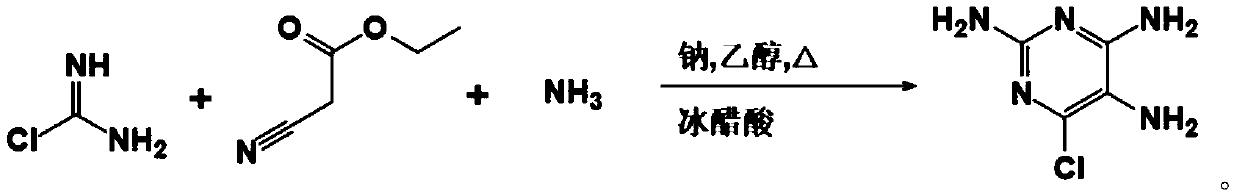

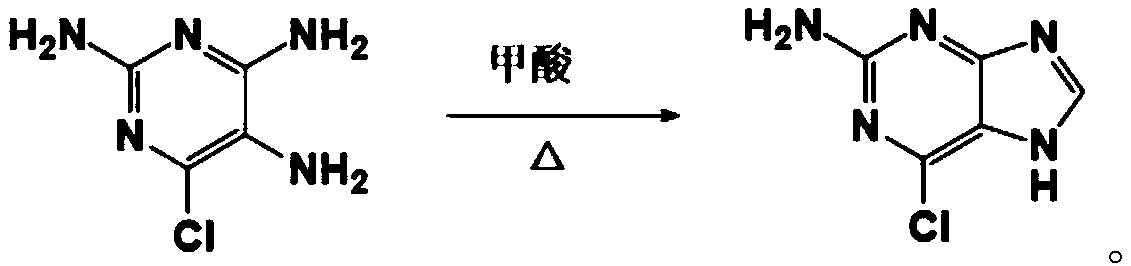

[0032] Such as figure 1 As shown, the present embodiment 1 provides a kind of synthetic method of 2-amino-6-chloropurine, comprises the following steps: step S1, one reaction, i.e. ethyl cyanoacetate, chloroformamidine hydrochloride, liquid ammonia and Sodium mixed reaction to generate intermediate; step S2, secondary reaction, that is, intermediate and formic acid mixed reaction; step S3, after cooling, slowly add 10% sodium hydroxide solution to the product of the secondary reaction, and thoroughly Mix until the mixture is just alkaline with litmus; and step S4, filter with a Buchner funnel, collect the solid by suction, and then dry to obtain the 2-amino-6-chloropurine.

[0033] Optionally, the molar ratio of ethyl cyanoacetate, chloroformamidine hydrochloride, liquid ammonia, sodium, and formic acid is 1:1.1-1.2:2-3:0.1:1-1.5.

[0034] The synthesis method of the present embodiment 1 selects ethyl cyanoacetate, chloroformamidine hydrochloride, and liquid ammonia as raw ma...

Embodiment 2

[0047] On the basis of Example 1, this Example 2 provides a kind of 2-amino-6-chloropurine, its structural formula is:

[0048]

[0049] For the specific structure and implementation process of 2-amino-6-chloropurine, please refer to the relevant discussion in Example 1, and details will not be repeated here.

Embodiment 3

[0051]On the basis of Example 1, this Example 3 provides an intermediate for synthesizing 2-amino-6-chloropurine, whose structural formula is:

[0052]

[0053] For the specific structure and implementation process of the intermediate, please refer to the related discussion of Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com