Polyimide grafted polyethylene glycol composite solid-solid phase change material and preparation method thereof

A technology of grafting polyethylene glycol and polyimide, which is applied in the field of polyimide grafted polyethylene glycol composite solid-solid phase change materials and its preparation, can solve the problem of toxic and harmful substances and high cost of crosslinking agents , Increase production costs and other issues, achieve good dispersion, reduce latent heat of phase change, and reduce the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of polyimide grafted polyethylene glycol composite solid-solid phase change material:

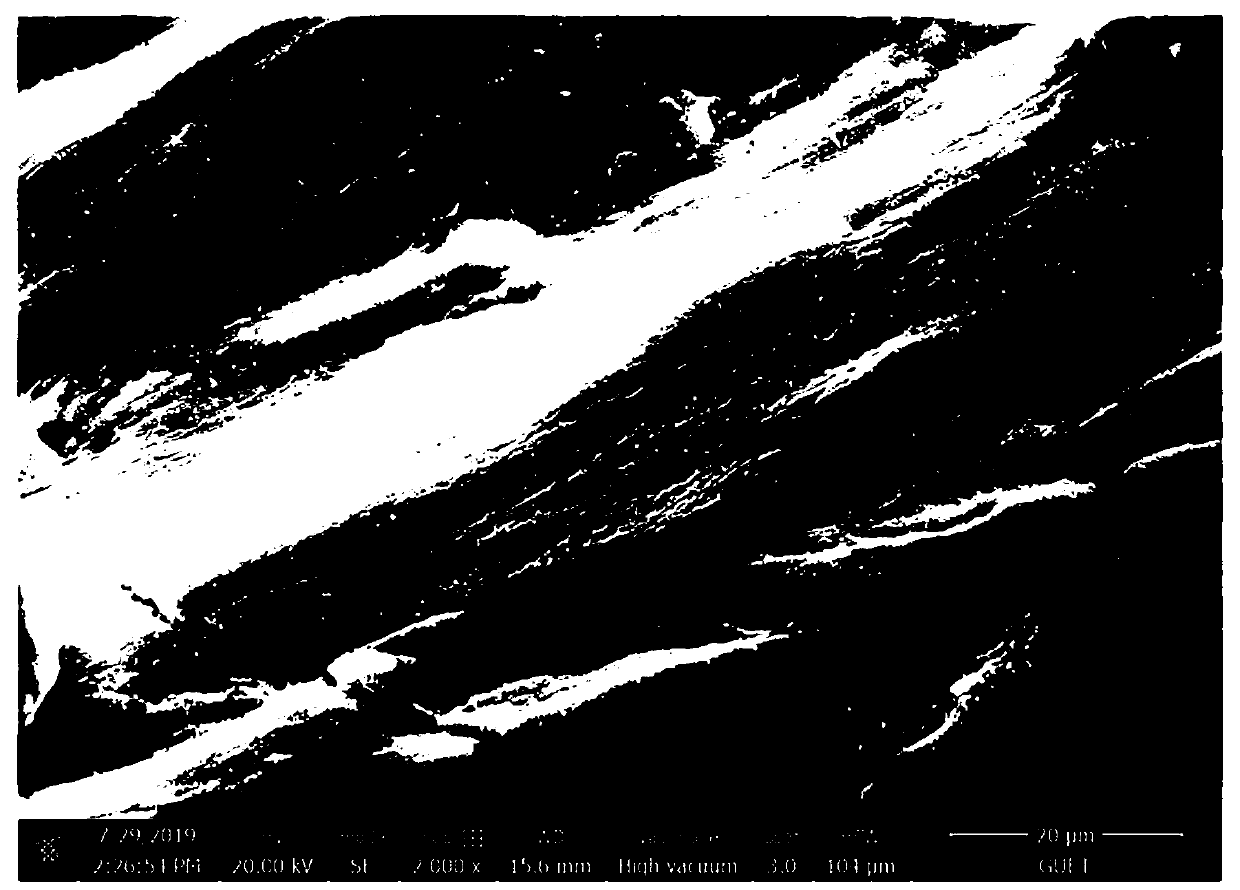

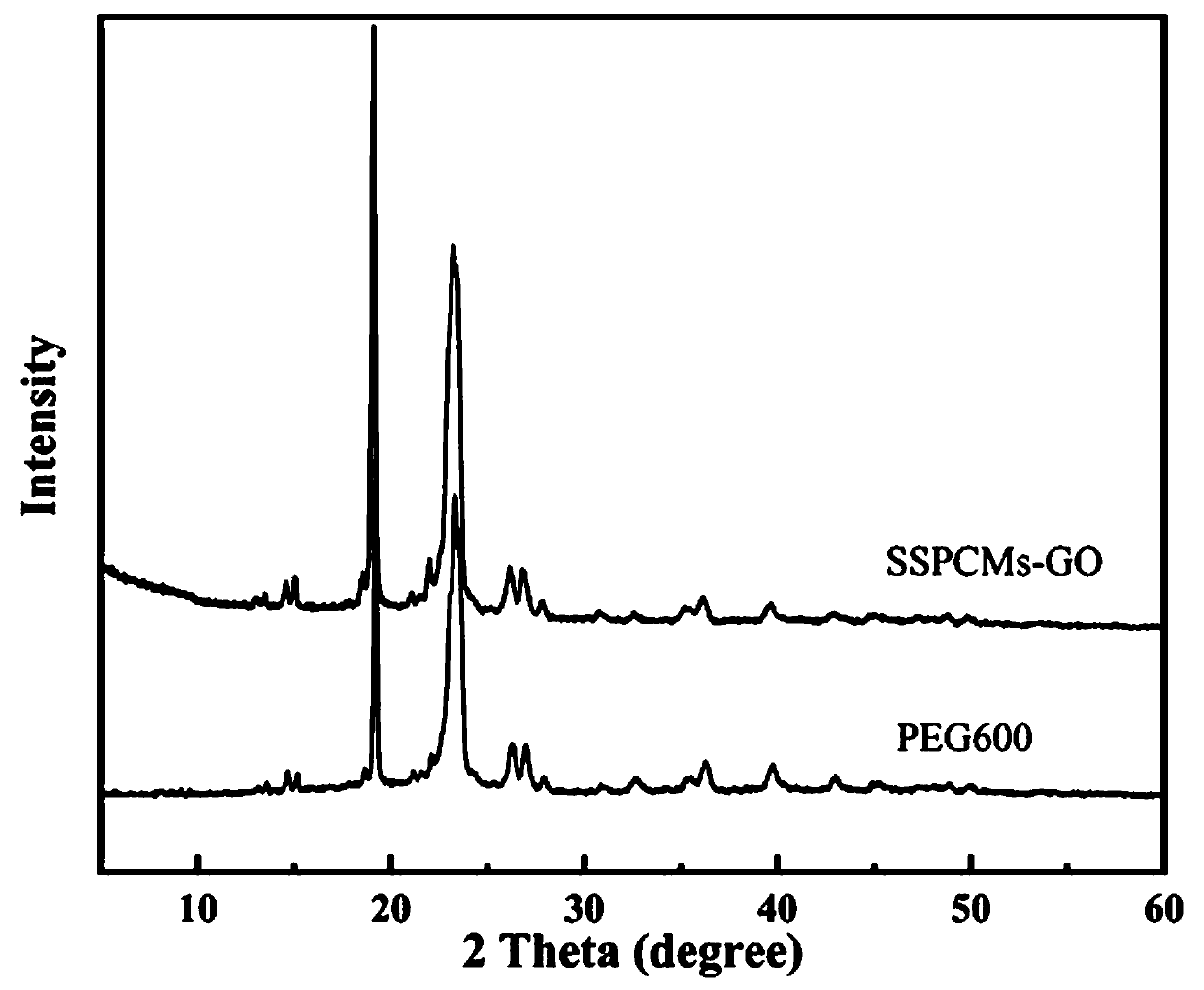

[0057] Step 1) Preparation of the mixed solution of graphene oxide modified polyimide precursor, pyromellitic dianhydride and 4,4-diaminodiphenyl ether according to the ratio of the amount of substance is 1:1, firstly mix 5.71 Add g of 4,4-diaminodiphenyl ether into a 250 mL three-necked flask, add 100 mL of N,N-dimethylformamide, and then Add 0.2 g of graphene oxide at a ratio of 1:0.035, ultrasonically disperse for 30 min, then transfer to an ice bath and mechanically stir for 30 min, and then divide 6.22 g of pyromellitic dianhydride at the same interval for 30 min. Three times were added into the three-necked flask, and the stirring was continued for 6 h to obtain a mixed solution of graphene oxide modified polyimide precursor.

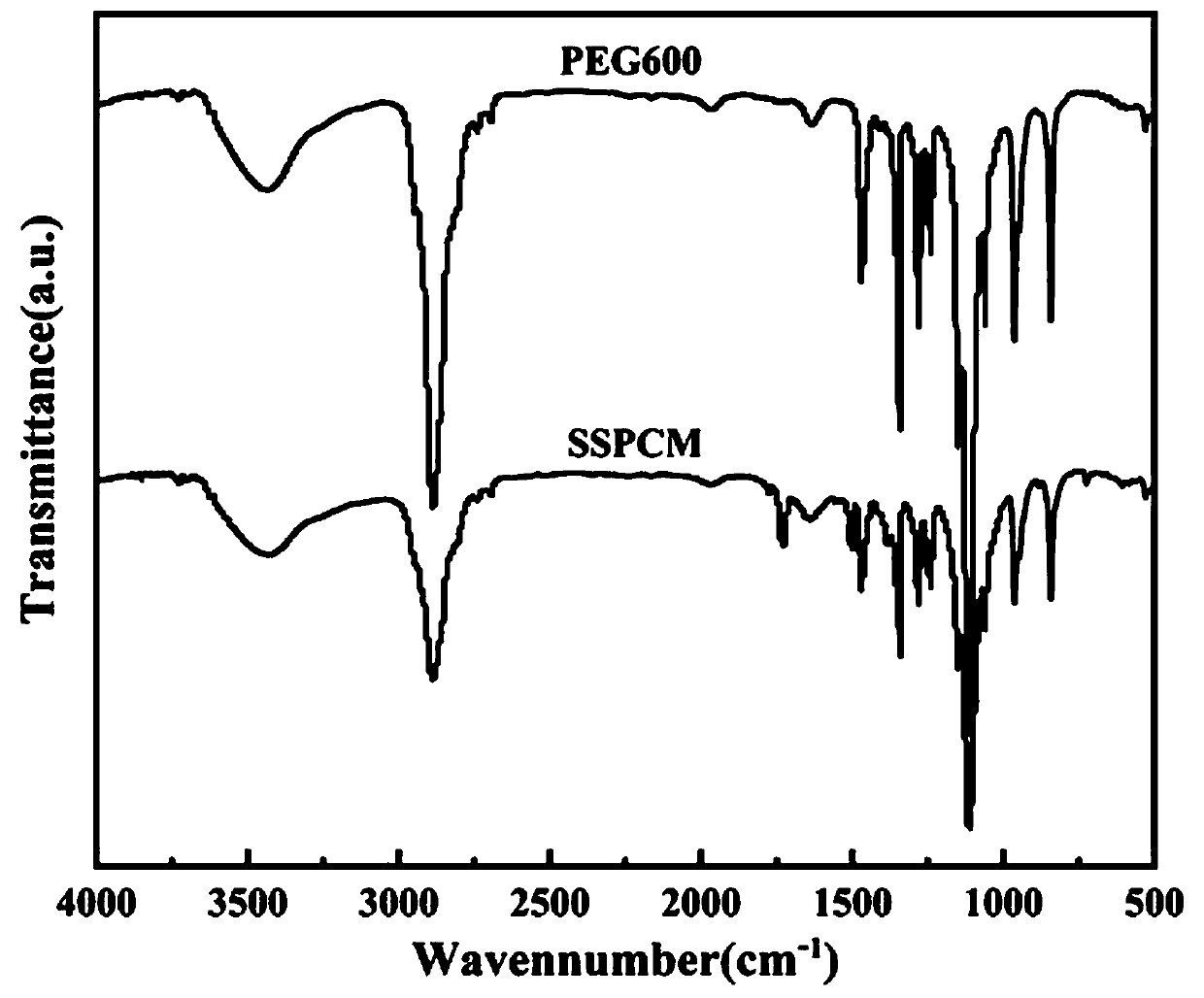

[0058] Step 2) Preparation of polyimide-based graphene oxide grafted polyethylene glycol composite solid-solid phase change materi...

Embodiment 2

[0068] A preparation method of a polyimide-based graphene oxide grafted polyethylene glycol composite solid-solid phase change material: the steps not specified in the specific steps are the same as the preparation method of the above-mentioned Example 1, the difference is that: The mass ratio of the mixed solution of the graphene oxide modified polyimide precursor and the molten polyethylene glycol is 1:1.

Embodiment 3

[0070] A preparation method of a polyimide-based graphene oxide grafted polyethylene glycol composite solid-solid phase change material: the steps not specified in the specific steps are the same as the preparation method of the above-mentioned Example 1, the difference is that: The mass ratio of the mixed solution of the graphene oxide modified polyimide precursor and the molten polyethylene glycol is 1:1.5.

[0071] In order to study the influence of the mass ratio of the mixed solution of the graphene oxide modified polyimide precursor and the melted polyethylene glycol on the performance of the composite phase change material, the material obtained in the above-mentioned Examples 2 and 3 was tested by DSC.

[0072] The mixed solution of graphene oxide modified polyimide precursor and the test result when the polyethylene glycol mass ratio of melting is 1:1 are as follows Figure 8 As shown, the melting temperature is 58.31 ℃, the crystallization temperature is 40.33 ℃, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com