Damping shock-absorbing thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and damping technology, which is applied in the field of thermoplastic elastomer, can solve the problems of application limitations, etc., and achieve the effects of improving mechanical properties, increasing anti-aging performance, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

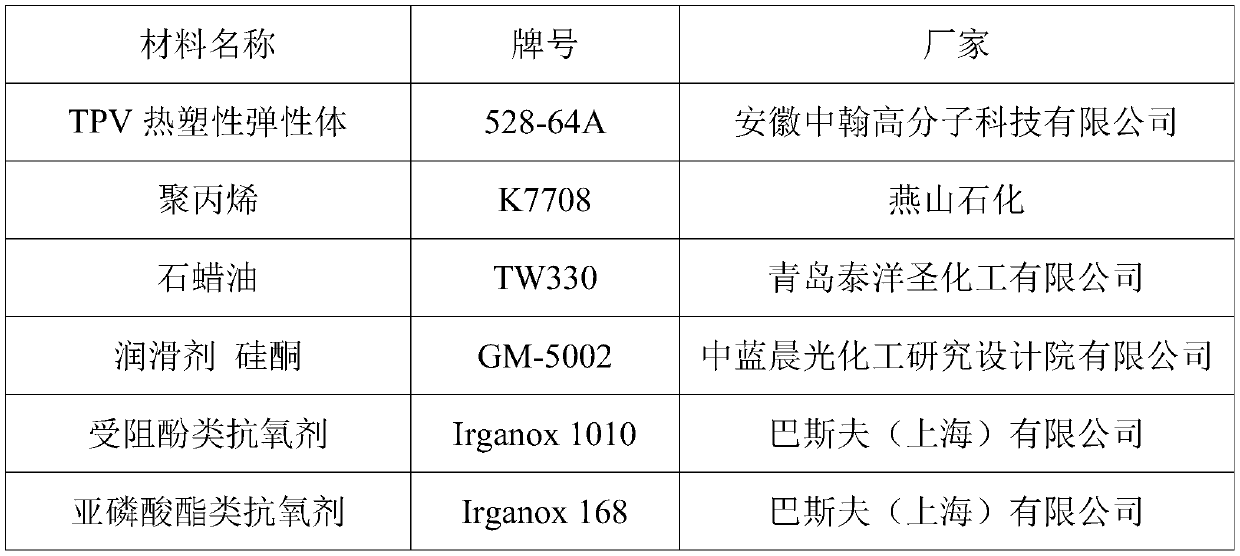

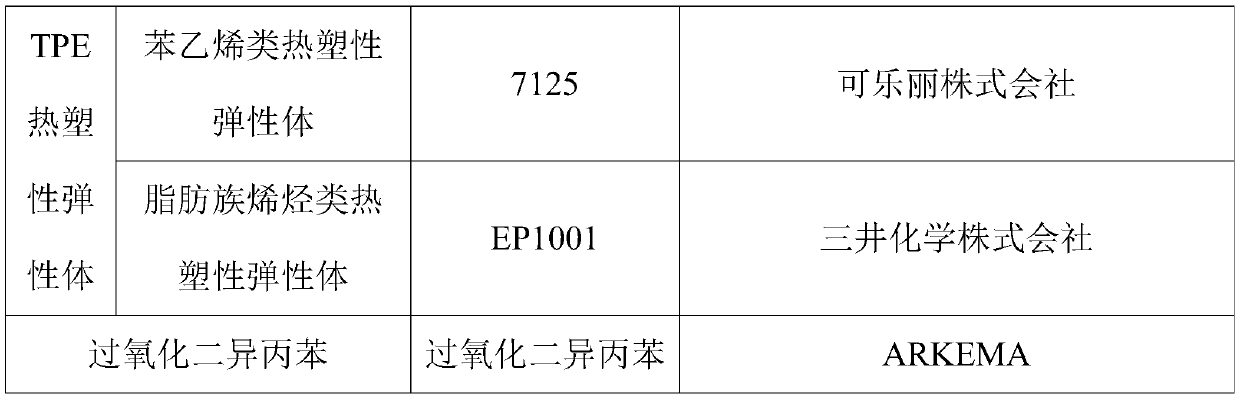

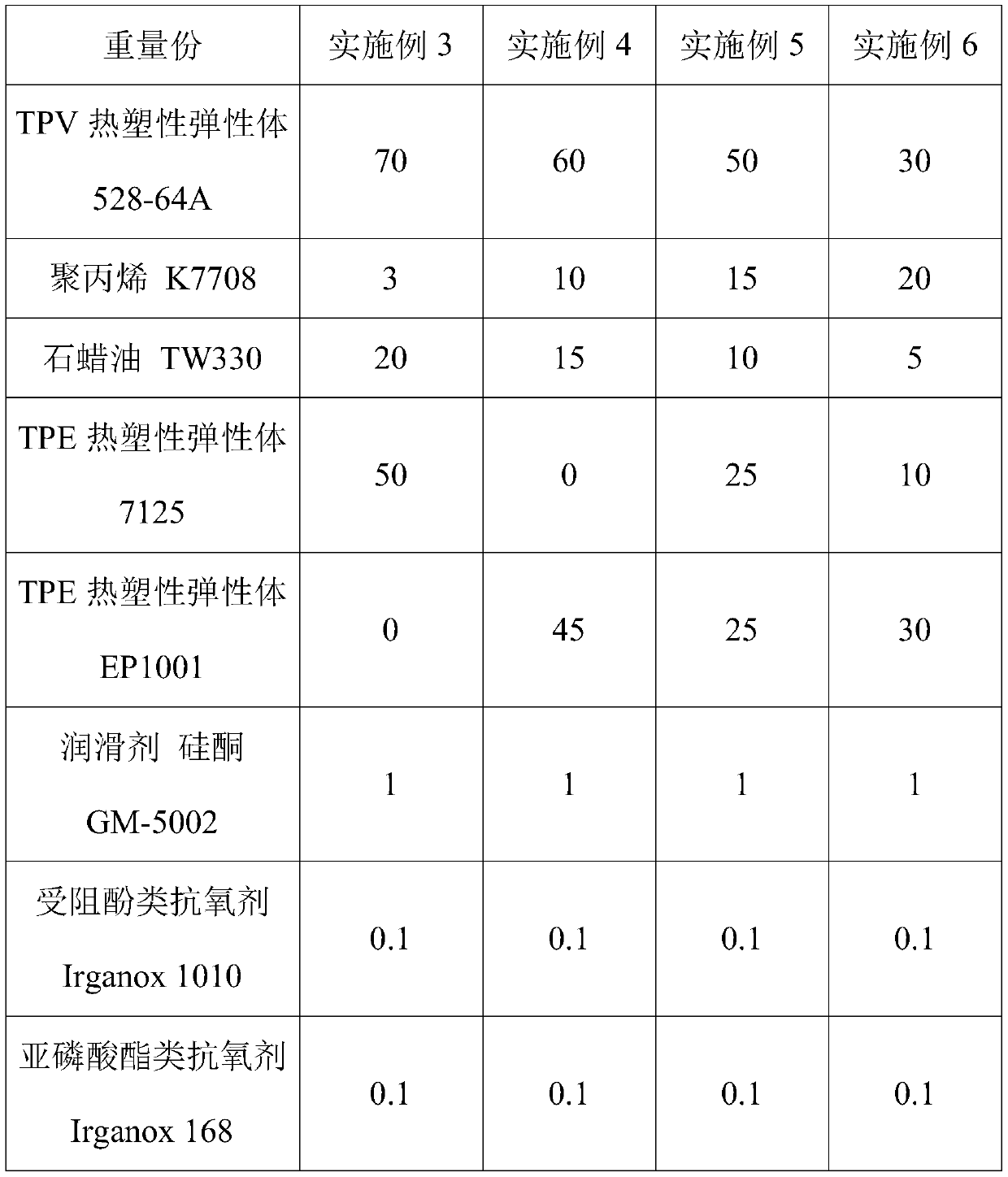

Method used

Image

Examples

Embodiment 1

[0021] A damping and shock-absorbing thermoplastic elastomer material, its raw materials include by weight: 20 parts of TPV thermoplastic elastomer, 80 parts of TPE thermoplastic elastomer, 2 parts of polyolefin resin, 20 parts of processing oil, benzophenone light stabilizer 0.1 part, 1 part of anti-aging agent, 0.6 part of dicumyl peroxide, wherein, TPE thermoplastic elastomer is aliphatic olefin thermoplastic elastomer and styrene thermoplastic elastomer;

[0022] The aliphatic olefin thermoplastic elastomer is a thermoplastic α-olefin copolymer, and its glass transition temperature Tg is 40°C;

[0023] Styrenic thermoplastic elastomers are tri-block copolymers or / and hydrogenated products of tri-block copolymers, which are terminated by polystyrene, and the middle segment is ethylene branched polydiene, and its glass transition temperature is -35 ℃;

[0024] The polyolefin resin is at least one of homopolypropylene, copolymerized polypropylene, high-density polyethylene, ...

Embodiment 2

[0029] A damping and shock-absorbing thermoplastic elastomer material, its raw materials include by weight: 80 parts of TPV thermoplastic elastomer, 10 parts of TPE thermoplastic elastomer, 30 parts of polyolefin resin, 2 parts of processing oil, 5 parts of processing aid, anti-aging agent 0.1 part, 0.8 part of dicumyl peroxide, wherein the TPE thermoplastic elastomer is an aliphatic olefin thermoplastic elastomer and a styrene thermoplastic elastomer;

[0030] The aliphatic olefin thermoplastic elastomer is a thermoplastic α-olefin copolymer, and its glass transition temperature Tg is 0°C;

[0031] Styrenic thermoplastic elastomers are tri-block copolymers or / and hydrogenated products of tri-block copolymers, which are terminated by polystyrene, and the middle segment is ethylene branched polydiene, and its glass transition temperature is 20°C ;

[0032] The polyolefin resin is at least one of homopolypropylene, copolymerized polypropylene, high-density polyethylene, and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com