Method for extracting collagen from cowhide

A collagen and extraction method technology, applied in the field of collagen extraction from cowhide, can solve problems such as long extraction time and increase protein impurities, and achieve the effects of improving thermal denaturation temperature, preventing excessive hydrolysis and reducing the probability of thermal denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

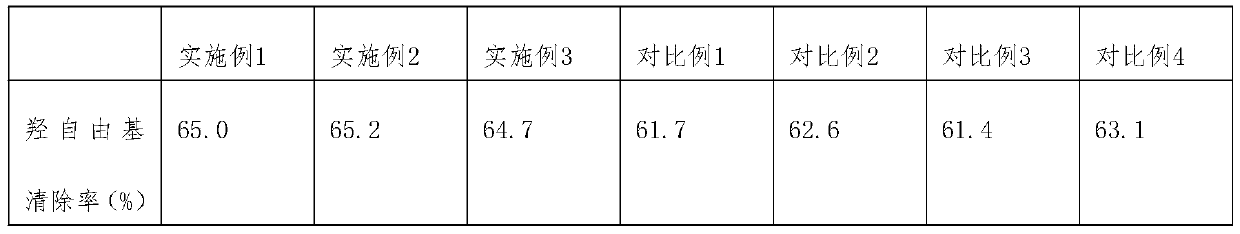

Examples

Embodiment 1

[0026] A method for extracting collagen in cowhide, comprising the following steps:

[0027] (1) Cowhide pretreatment: put the cowhide into compound enzyme solution A whose temperature is 22°C which is 2 times its mass, and soak it at a constant temperature for 150 minutes, drain it, rinse it with clean water, and cut the cowhide into small pieces of 3-5cm ;Put the cowhide block into the protective solution and soak for 50min, drain and dry in the air;

[0028] (2) Miscellaneous protein removal: Put the cowhide piece treated in step (1) into a compound alkali solution at 30°C for 15 minutes, then soak it in a slightly acidic solution for 5 minutes, drain it, and rinse it with clean water Afterwards, dry and set aside;

[0029] (3) Preparation of kraft pulp: mix the processed cowhide block, ice water and protective agent in step (2), and send it into a homogenizer for homogenization for 10 minutes to obtain kraft pulp;

[0030] (4) Collagen extraction: add its mass 0.005% com...

Embodiment 2

[0041] A method for extracting collagen in cowhide, comprising the following steps:

[0042] (1) Cowhide pretreatment: put the cowhide into compound enzyme solution A which is 2.4 times its mass and the temperature is 24°C, soak it at a constant temperature for 120 minutes, drain it, rinse it with clean water, and cut the cowhide into small pieces of 3-5cm ;Put the cowhide block into the protective solution and soak for 55min, drain and dry in the air;

[0043] (2) Miscellaneous protein removal: Put the cowhide piece treated in step (1) into a compound alkali solution at 32°C for 12 minutes, then soak it in a slightly acidic solution for 5 minutes, drain it, and rinse it with clean water Afterwards, dry and set aside;

[0044] (3) Preparation of kraft pulp: mix the processed cowhide block, ice water and protective agent in step (2), and send it into a homogenizer for homogenization for 8 minutes to obtain kraft pulp;

[0045] (4) Collagen extraction: add its mass 0.005% comp...

Embodiment 3

[0056] A method for extracting collagen in cowhide, comprising the following steps:

[0057] (1) Cowhide pretreatment: put the cowhide into the compound enzyme solution A whose temperature is 25°C which is 3 times its mass, and soak it at a constant temperature for 120 minutes, drain it, rinse it with clean water, and cut the cowhide into small pieces of 3-5cm ;Put the cowhide block into the protective solution and soak for 60min, drain and dry in the air;

[0058] (2) Miscellaneous protein removal: Put the cowhide piece treated in step (1) into a compound alkali solution at 35°C for 10 minutes, then soak it in a slightly acidic solution for 5-6 minutes, drain it, and wash it with clean water After rinsing, dry and set aside;

[0059] (3) Preparation of kraft pulp: mix the processed cowhide block, ice water, and protective agent in step (2), and send it into a high-speed homogenizer for homogenization for 10 minutes to obtain kraft pulp;

[0060] (4) Collagen extraction: add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com