Aluminum powder/polyvinylidene fluoride composite particle and its preparation method and application

A polyvinylidene fluoride and composite particle technology, which is used in transportation and packaging, metal processing equipment, explosives, etc., can solve the problems of slow combustion reaction rate and reduced active aluminum content, and achieve fast reaction speed, anti-oxidation, good quality The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

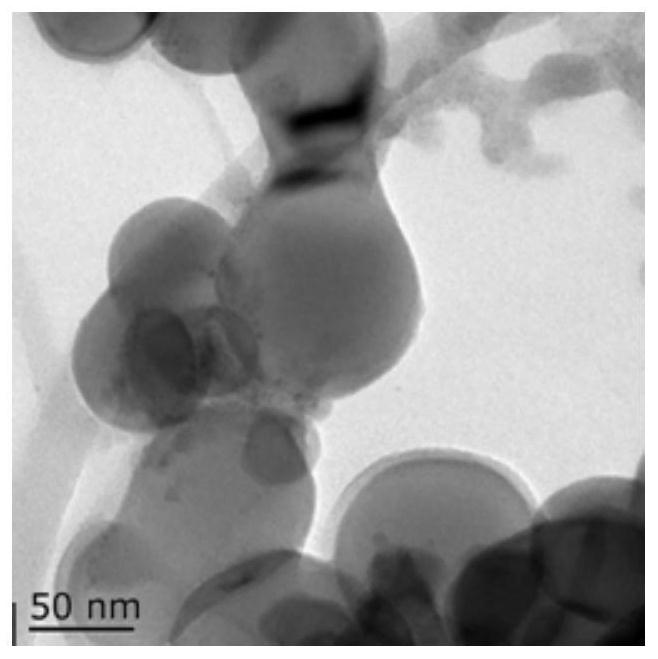

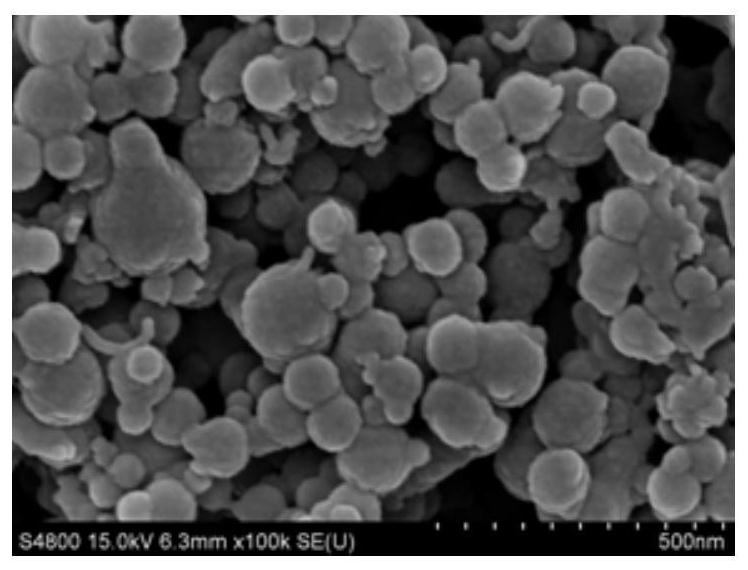

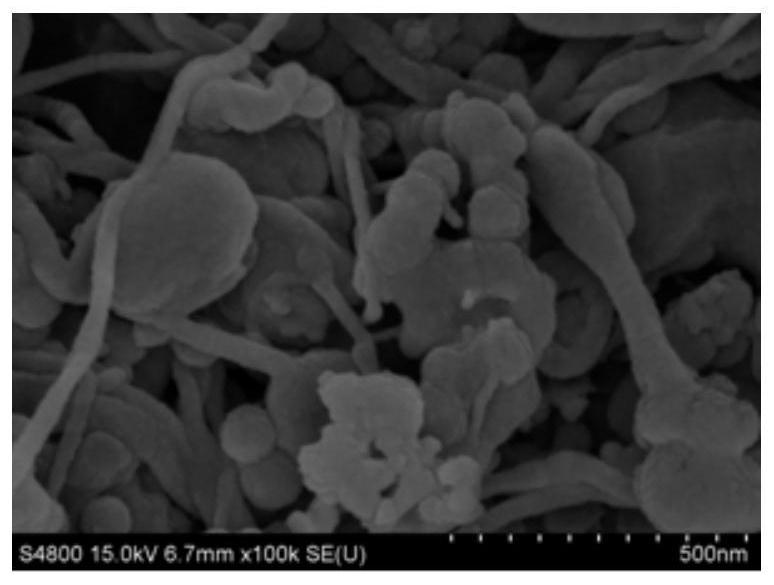

Embodiment 1

[0026] Take 3.2g of aluminum powder, 0.8g of PVDF, 90mL of acetone, and 60mL of dimethylformamide to make a suspension. The needle diameter is selected as 0.4mm, the spray rate is set to 0.5mL / h, the receiving distance is 15cm, and the electrostatic voltage is 16kV, and the Al / PVDF composite particles are collected on the receiving plate. Characterized by transmission electron microscope, scanning electron microscope and burning rate tester. It is found that Al / PVDF composite particles have a typical core-shell structure, good micro-morphology, good dispersion, and a burning speed of 68m / s.

Embodiment 2

[0028] Take 0.4g of aluminum powder, 0.1g of PVDF, 12mL of acetone, and 8mL of dimethylformamide to make a suspension. The needle diameter is selected as 0.5mm, the spray rate is set to 1mL / h, the receiving distance is 10cm, and the electrostatic voltage is 12kV, and Al / PVDF composite particles are collected on the receiving plate. Characterized by transmission electron microscope, scanning electron microscope and burning rate tester. It is found that the Al / PVDF composite particles have a typical core-shell structure, good micro-morphology, and good dispersion. The burning speed is 72m / s.

Embodiment 3

[0030] Take 1.2g of aluminum powder, 0.3g of PVDF, 30mL of acetone, and 20mL of dimethylformamide to make a suspension. The diameter of the needle is 0.45mm, the spray rate is set to 2mL / h, the receiving distance is 20cm, the electrostatic voltage is 19kV, and Al / PVDF composite particles are collected on the receiving plate. Characterized by transmission electron microscope, scanning electron microscope and burning rate tester. It is found that Al / PVDF composite particles have a typical core-shell structure, good micro-morphology, good dispersion, and a burning speed of 75m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com