A kind of high light black PLA masterbatch and preparation method thereof

A black and masterbatch technology, applied in the field of PLA, can solve the problems of not enough to achieve high light and low blackness, the mechanical properties of PLA have not been improved too much, and the application field is limited, so as to improve the brightness and tensile strength , easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

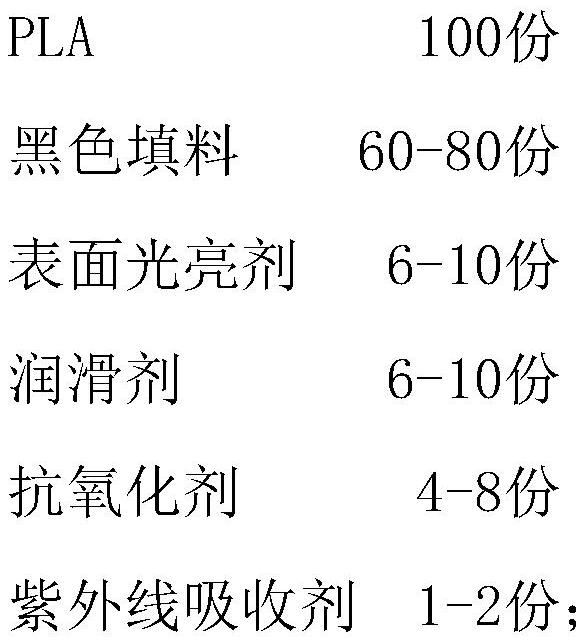

[0023] A high-gloss black PLA masterbatch, comprising the following raw materials in parts by weight:

[0024]

[0025]

[0026] Described black filler is made through the following steps:

[0027] (1) Add 4 parts by weight of cornstarch and 10 parts by weight of microcrystalline cellulose into 100 parts by weight of water, then heat up to 90°C, stir and react for 2 hours, then filter, dry, and pulverize to obtain a skeleton matrix;

[0028] (2) Add 10 parts by weight of the skeleton matrix and 20 parts by weight of nano-carbon black into 100 parts by weight of water, ultrasonically disperse, and then filter and dry to obtain the black filler.

[0029] Wherein, the particle size of the microcrystalline cellulose is 40 μm, the particle size of the skeleton matrix is 150 μm, and the particle size of the nano-carbon black is 20 nm.

[0030] Wherein, the oscillation frequency of the ultrasonic dispersion is 25KHz, the time is 30min, and the temperature is 40°C.

[0031] ...

Embodiment 2

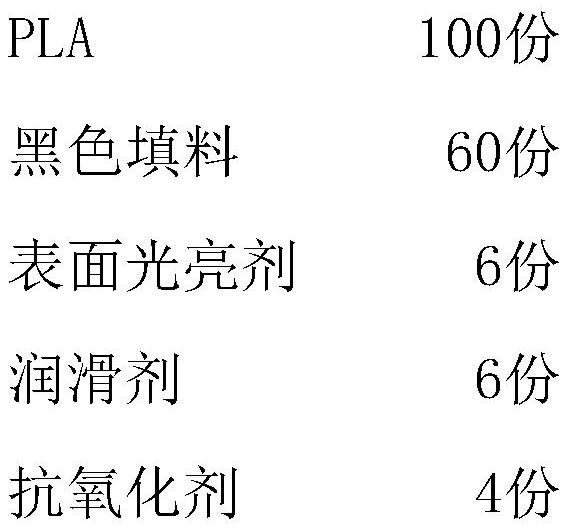

[0038] A high-gloss black PLA masterbatch, comprising the following raw materials in parts by weight:

[0039]

[0040] Described black filler is made through the following steps:

[0041] (1) Add 10 parts by weight of cornstarch and 20 parts by weight of microcrystalline cellulose into 100 parts by weight of water, then raise the temperature to 95° C., stir and react for 3 hours, then filter, dry, and pulverize to obtain a skeleton matrix;

[0042] (2) Add 20 parts by weight of the skeleton matrix and 40 parts by weight of nano-carbon black into 100 parts by weight of water, ultrasonically disperse, and then filter and dry to obtain the black filler.

[0043] Wherein, the particle size of the microcrystalline cellulose is 50 μm, the particle size of the skeleton matrix is 200 μm, and the particle size of the nano-carbon black is 30 nm.

[0044] Wherein, the oscillation frequency of the ultrasonic dispersion is 35KHz, the time is 40min, and the temperature is 50°C.

[0...

Embodiment 3

[0052] A high-gloss black PLA masterbatch, comprising the following raw materials in parts by weight:

[0053]

[0054] Described black filler is made through the following steps:

[0055] (1) Add 7 parts by weight of cornstarch and 15 parts by weight of microcrystalline cellulose to 100 parts by weight of water, then raise the temperature to 93° C., stir and react for 2.5 hours, then filter, dry, and pulverize to obtain a skeleton matrix;

[0056] (2) Add 15 parts by weight of the skeleton matrix and 30 parts by weight of nano-carbon black into 100 parts by weight of water, ultrasonically disperse, and then filter and dry to obtain the black filler.

[0057] Wherein, the particle size of the microcrystalline cellulose is 44.8 μm, the particle size of the skeleton matrix is 173.2 μm, and the particle size of the nano-carbon black is 25 nm.

[0058] Wherein, the oscillation frequency of the ultrasonic dispersion is 30KHz, the time is 35min, and the temperature is 45°C.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com