Vinyl chloride rectification temperature control method based on fuzzy neural network

A technology of fuzzy neural network and temperature control method, which is applied in the direction of temperature control, self-adaptive control and general control system using electric mode, can solve the problems of control level staying, difficult to achieve satisfactory purification effect, etc., and achieves the goal of improving control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings.

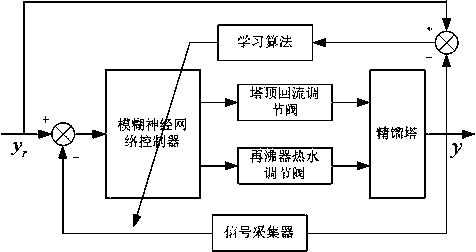

[0014] refer to figure 1 , a method for temperature control of vinyl chloride rectification based on fuzzy neural network, comprising the following steps: (1) signal acquisition; (2) fuzzy neural network control; (3) learning algorithm.

[0015] The signal acquisition in the step (1) is to discretely sample the feed flow, column top temperature, middle temperature, column kettle temperature, and column top reflux flow through the signal collector at intervals of 10 seconds (one sampling period), and analyze the The current sampled value and the past 5 consecutive sampled values are subjected to moving average filtering, the maximum and minimum values are removed from the 5 consecutively sampled values, and the remaining 3 values are summed and averaged to obtain the filter value.

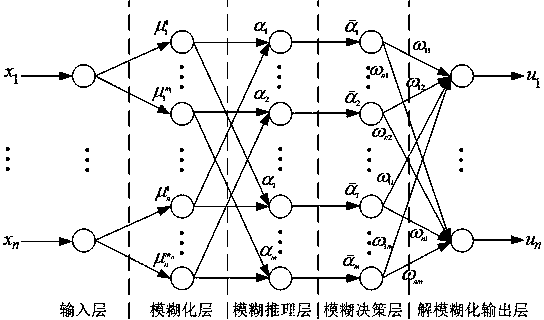

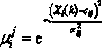

[0016] The fuzzy neural network control in the step (2) has a total of 5 layers of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com