Polymer solar cell and preparation method thereof

A solar cell and polymer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low energy conversion efficiency, and achieve the effects of improving energy conversion efficiency, improving energy conversion efficiency, and improving dissociation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

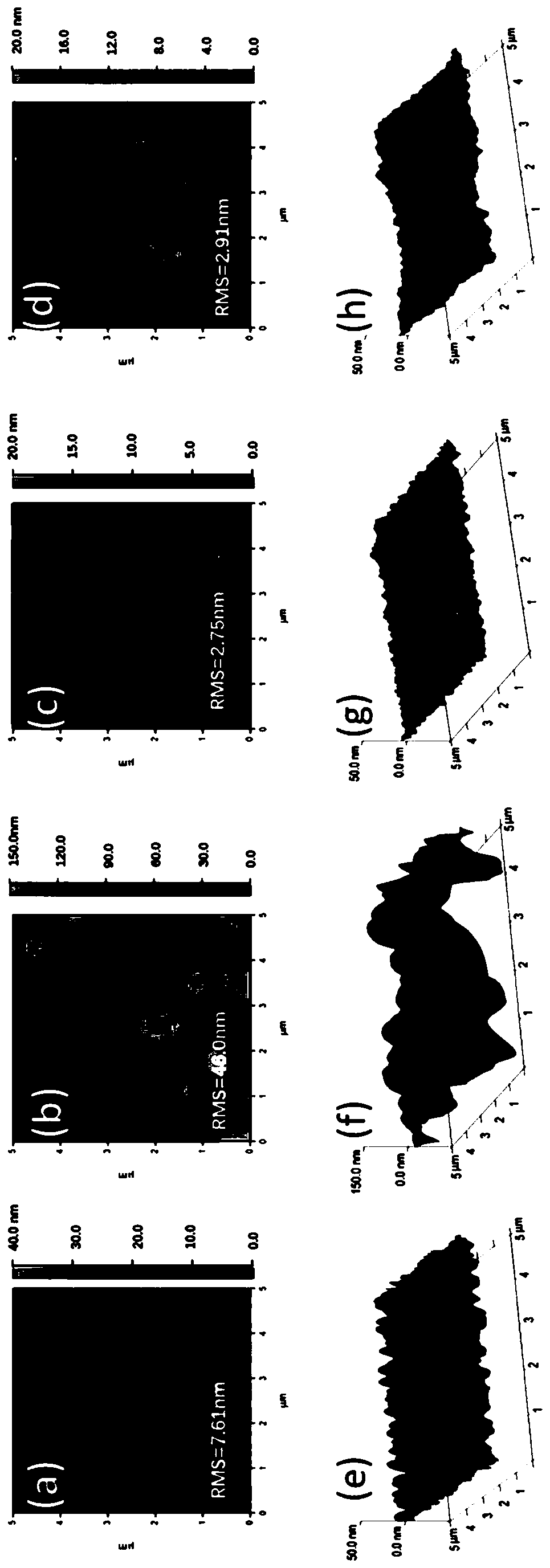

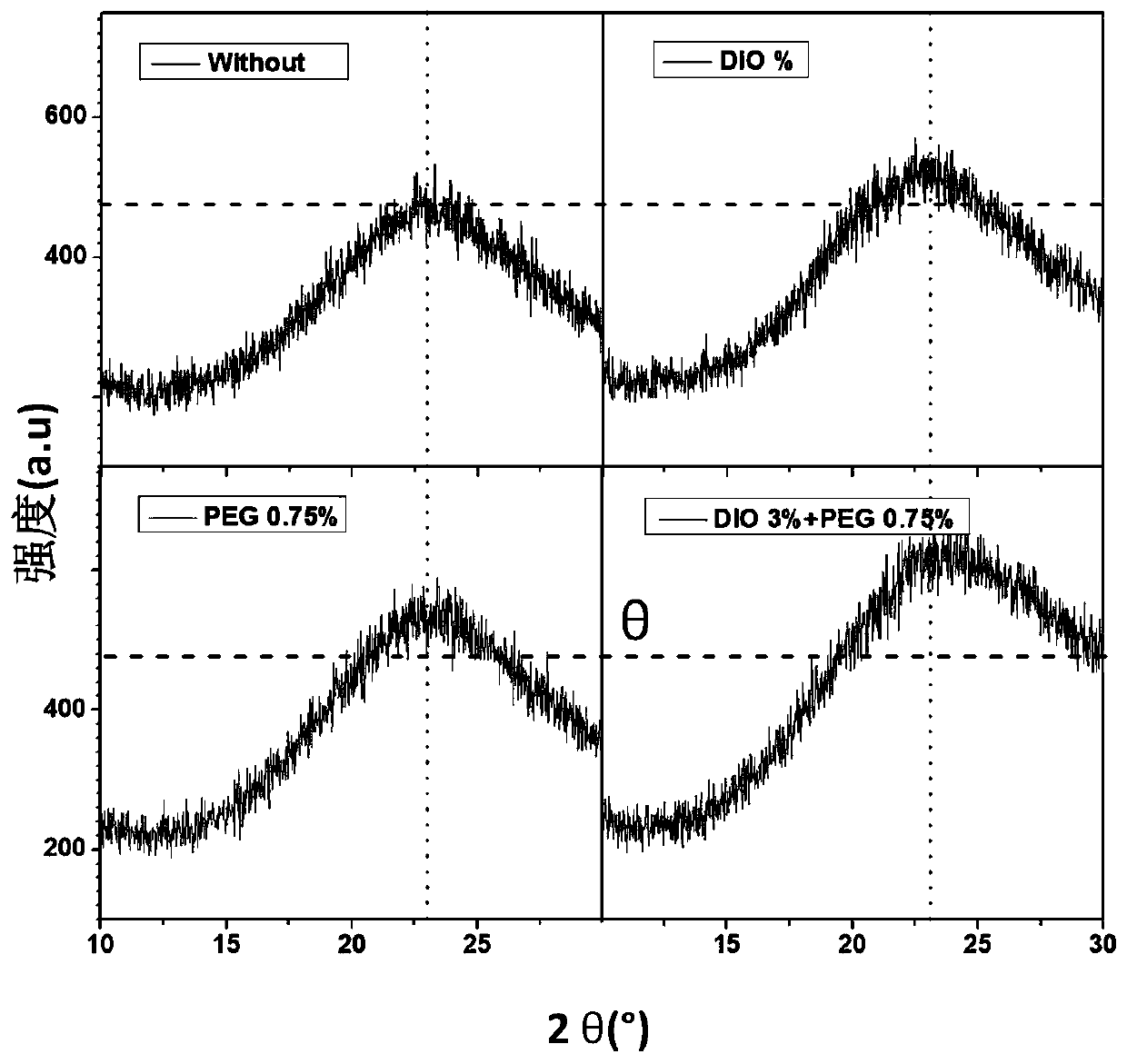

[0062] Preparation of active layer solution

[0063] (1) With PTB7: PC 71 The BM mixed solution is the first active layer solution;

[0064] (2) Using chlorobenzene as a solvent, in a PTB7:PC71BM mixed solution with a mass / volume (w / v) ratio of 10mg / ml:15mg / ml, mix PTB7:PC by volume 71 The second active layer solution was prepared with 3% DIO of the BM mixed solution and stored at room temperature;

[0065] (3) PTB7:PC with a mass / volume (w / v) ratio of 10mg / ml:15mg / ml 71 BM mixed solution incorporated by volume accounted for PTB7:PC 71 The third active layer solution was prepared by 0.75% PEG of the BM mixed solution, and stored at room temperature;

[0066] (4) PTB7:PC with a mass / volume (w / v) ratio of 10mg / ml:15mg / ml 71 Simultaneous incorporation of PTB7:PC by volume in the BM mixed solution 71 The fourth active layer solution was prepared by 3% DIO and 0.75% PEG of the BM mixed solution, and stored at room temperature;

[0067] Use a cotton swab dipped in ITO lotion ...

Embodiment 1

[0089] Preparation and performance testing of polymer solar cells doped with 3% DIO and 0.75% PEG additives

[0090] PTB7:PC at a mass / volume (w / v) ratio of 10mg / ml:15mg / ml using chlorobenzene as solvent 71 BM mixed solution incorporated by volume accounted for PTB7:PC 71 The active layer solution was prepared with 3% DIO and 0.75% PEG of BM mixed solution and stored at room temperature.

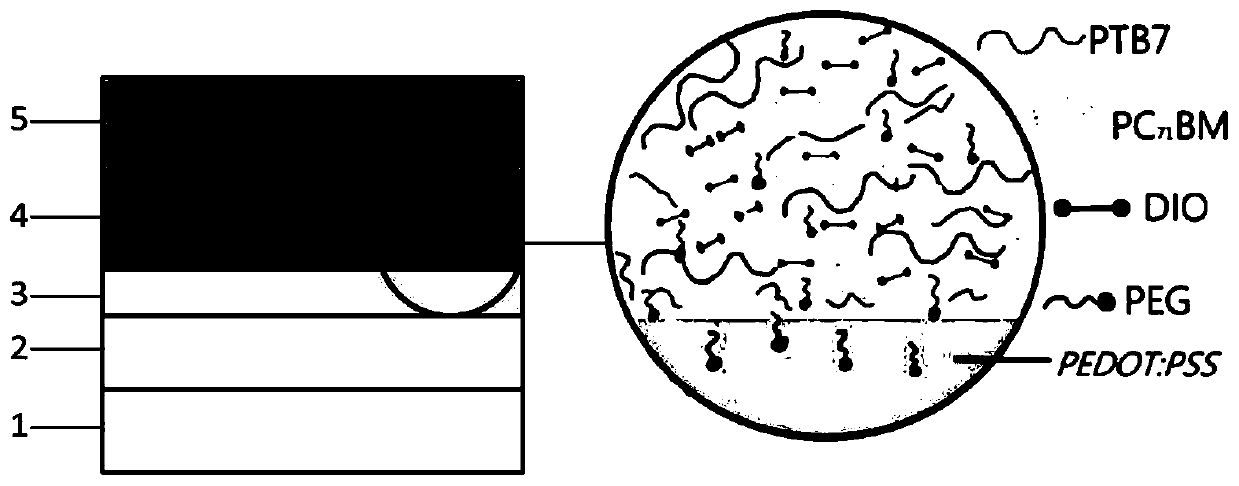

[0091] The operation was exactly the same as that of Comparative Example 1 except in the active layer solution. image 3 Schematic diagram of the fabricated device structure.

[0092] The performance of the polymer solar cell was measured according to the method described in Comparative Example 1, and the results are shown in Table 1. The current density-voltage characteristic curve of the prepared polymer solar cell is as follows: image 3 shown.

Embodiment 2

[0094] Preparation and performance testing of polymer solar cells doped with 3% DIO and 0.25% PEG additives

[0095] The procedure was exactly the same as in Example 1, except that the content of PEG in the active layer solution was 0.25% by volume. The performance of the polymer solar cell was measured according to the method described in Comparative Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com