Single-particle and secondary-particle mixed high-energy-density graphite negative electrode material and preparation method thereof

A technology with high energy density and secondary particles, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of negative electrode material tap density, discharge capacity, primary efficiency, and secondary compaction of the pole piece to be further improved, and achieve good Effects of cycle performance, improvement of processing performance, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

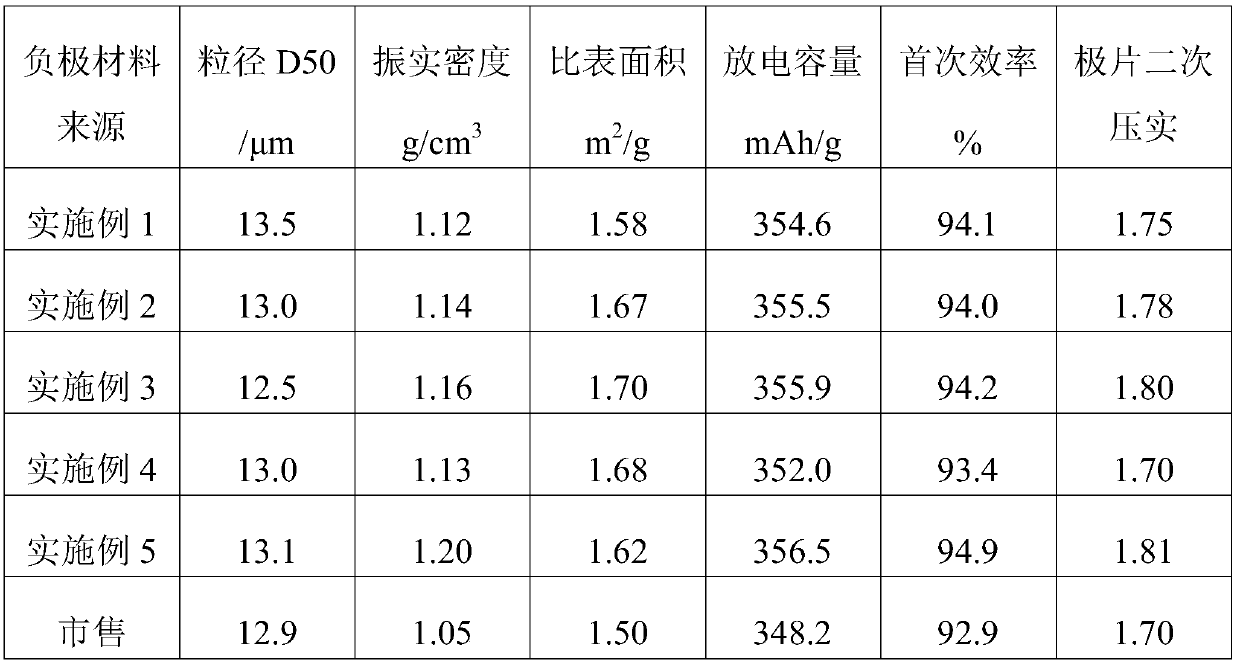

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a kind of single particle, the preparation method of the high energy density graphite negative electrode material that secondary particle mixes, comprises the following steps:

[0026] (1) first crush the petroleum coke, and dry it in a drier with a temperature of 100°C and a rotation speed of 10r / min for 0.5h to obtain a coarse powder with a particle size of less than 1.8mm;

[0027] (2) Finely grinding and shaping the coarse powder obtained in step (1) to obtain a fine powder with a D50 particle size value of 6.5 μm;

[0028] (3) subjecting the fine powder obtained in step (2) to high-temperature graphitization treatment at 2400° C. for 24 hours to obtain a single-particle graphitized material;

[0029] (4) Mix the fine powder obtained in step (2) with asphalt in a weight ratio of 100:8, and carry out surface modification treatment at 300°C for 8 hours under the protection of nitrogen gas to obtain a secondary particles;

[0030] (5) The sec...

Embodiment 2

[0033] This embodiment provides a kind of single particle, the preparation method of the high energy density graphite negative electrode material that secondary particle mixes, comprises the following steps:

[0034] (1) First crush the pitch coke and dry it in a dryer at a temperature of 300°C and a rotation speed of 20r / min for 3 hours to obtain a coarse powder with a particle size of less than 1.5mm;

[0035] (2) Finely grinding and shaping the coarse powder obtained in step (1) to obtain a fine powder with a D50 particle size value of 12.5 μm;

[0036] (3) subjecting the fine powder obtained in step (2) to high-temperature graphitization treatment at 3000° C. for 48 hours to obtain a single-particle graphitized material;

[0037] (4) Mix the fine powder obtained in step (2) with asphalt in a weight ratio of 100:12, and carry out surface modification treatment at 600°C for 16 hours under the protection of nitrogen gas to obtain a secondary particles;

[0038] (5) The seco...

Embodiment 3

[0041] This embodiment provides a method for preparing a high energy density graphite negative electrode material mixed with single particles and secondary particles, comprising the following steps:

[0042] (1) first crush the needle coke, and dry it in a drier with a temperature of 100°C and a rotation speed of 10r / min for 3 hours to obtain a coarse powder with a particle size of less than 2mm;

[0043] (2) Finely grinding and shaping the coarse powder obtained in step (1) to obtain a fine powder with a D50 particle size value of 6.5 μm;

[0044] (3) subjecting the fine powder obtained in step (2) to a high-temperature graphitization treatment at 2400° C. for 48 hours to obtain a single-particle graphitized material;

[0045] (4) Mix the fine powder obtained in step (2) with asphalt in a weight ratio of 100:8, and carry out surface modification treatment at 300°C for 16 hours under the protection of nitrogen gas to obtain a secondary powder with a D50 particle size of 18 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com