All-solid-waste cementing material synergistically prepared from steel slag and multi-objective optimization method

A multi-objective optimization and cementitious material technology, which is applied in the field of steel slag collaborative preparation of solid waste cementitious materials and multi-objective optimization, can solve the problems of low technical content, low added value, and difficult resource utilization, and achieve low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

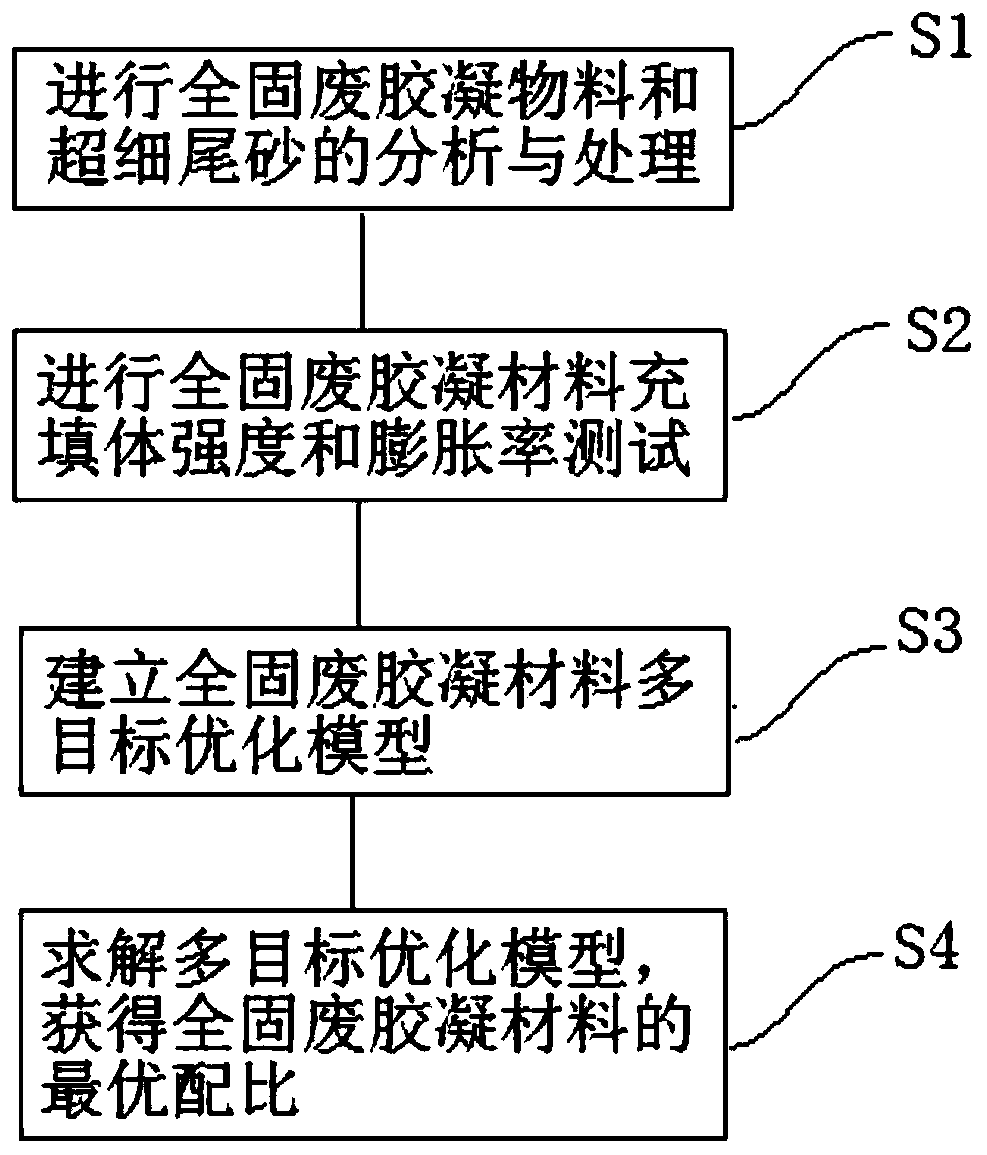

[0068] A multi-objective optimization method for preparing ultrafine tailings and solid waste cementitious materials with steel slag synergistically desulfurized gypsum, including the following steps:

[0069] Step 1. Analysis and treatment of all solid waste cementitious materials test materials

[0070]Drying, screening and grinding of the solid waste materials and ultra-fine tailings filling aggregates prepared from steel slag and industrial by-product gypsum to prepare solid waste cementitious materials, and the particle size analysis and eigenvalue calculation of the materials are carried out.

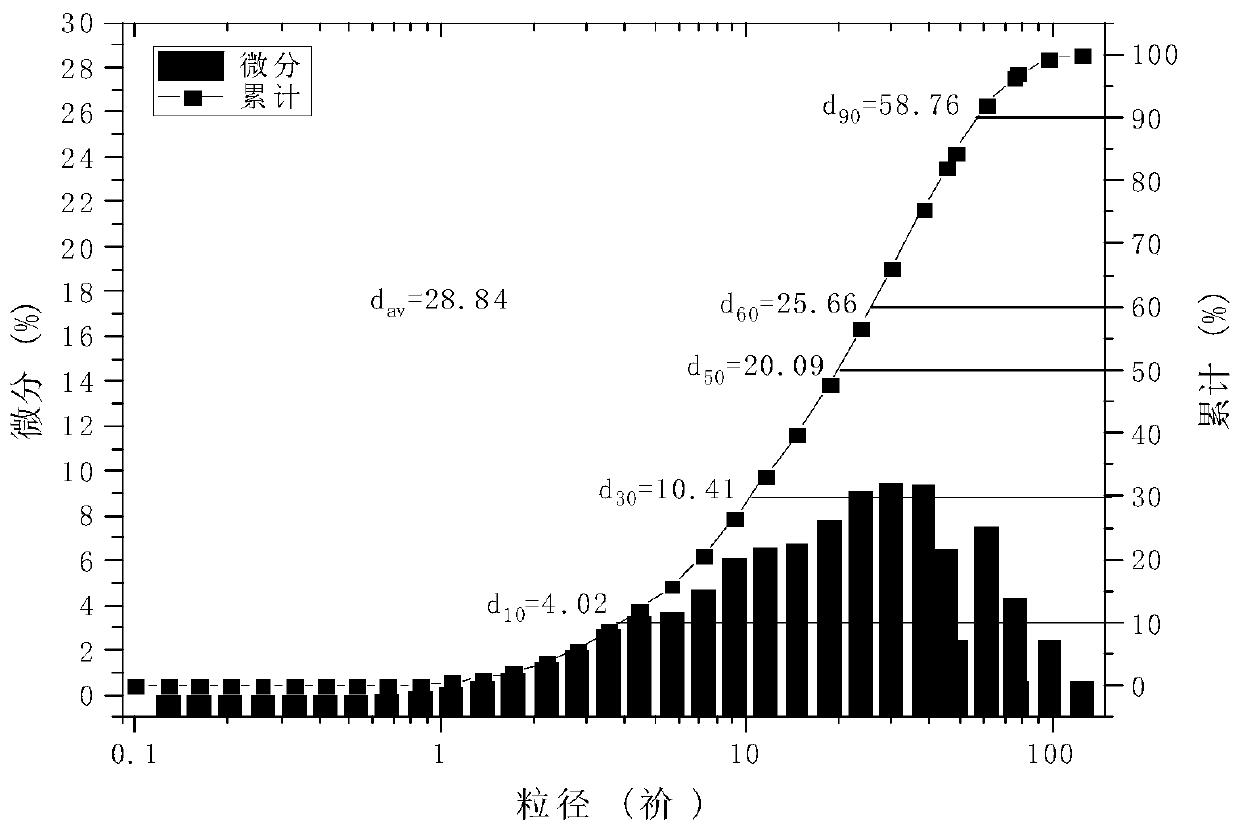

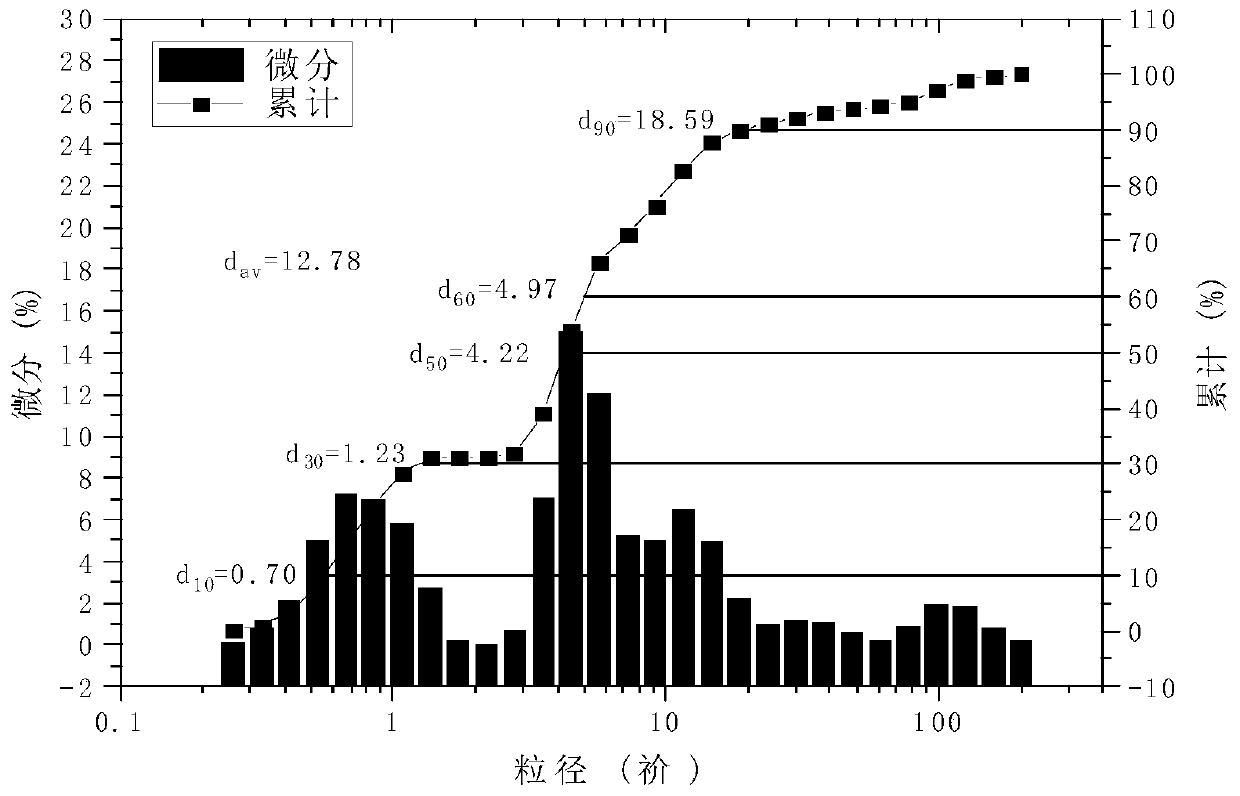

[0071] (1) The particle size distribution curve of steel slag powder is shown in figure 2 . Thus, the average particle size d of steel slag powder is obtained av = 28.84 μm, d 10 = 4.02 μm, d 30 = 10.41 μm, d 50 = 20.09 μm, d 60 = 25.66 μm, d 90 =58.76μm; where, d 10 Indicates that particles smaller than the average particle size account for 10% of the total number of par...

Embodiment 2

[0115] A multi-objective optimization method for preparing ultrafine tailings and solid waste cementitious materials with steel slag and fluorine gypsum, including the following steps:

[0116] Step 1. Analysis and treatment of all solid waste cementitious materials test materials

[0117] Drying, screening and grinding of the solid waste materials and ultra-fine tailings filling aggregates prepared from steel slag and industrial by-product gypsum to prepare solid waste cementitious materials, and the particle size analysis and eigenvalue calculation of the materials are carried out.

[0118] (1) The particle size distribution curve of steel slag powder is shown in figure 2 . Thus, the average particle size d of steel slag powder is obtained av = 28.84 μm, d 10 = 4.02 μm, d 30 = 10.41 μm, d 50 = 20.09 μm, d 60 = 25.66 μm, d 90 =58.76μm; non-uniformity coefficient C u = d 60 / d 10 =6.38, coefficient of curvature The fineness of steel slag powder is 18%. The minera...

Embodiment 3

[0158] A multi-objective optimization method for preparing ultra-fine tailings and solid waste cementitious materials with steel slag and desulfurization ash, including the following steps:

[0159] Step 1. Analysis and treatment of all solid waste cementitious materials test materials

[0160] Drying, screening and grinding of the solid waste materials and ultra-fine tailings filling aggregates prepared from steel slag and industrial by-product gypsum to prepare solid waste cementitious materials, and the particle size analysis and eigenvalue calculation of the materials are carried out.

[0161] (1) The particle size distribution curve of steel slag powder is shown in figure 2 . Thus, the average particle size d of steel slag powder is obtained av = 28.84 μm, d 10 = 4.02 μm, d 30 = 10.41 μm, d 50 = 20.09 μm, d 60 = 25.66 μm, d 90 =58.76μm; non-uniformity coefficient C u = d 60 / d 10 =6.38, coefficient of curvature The fineness of steel slag powder is 18%. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com