A method for deep recovery of tellurium by cascade swirl electrolysis

A swirl electrolysis and cascade technology, applied in electrolysis components, electrolysis process, element selenium/tellurium, etc., can solve problems such as low electrolysis speed, low equipment capacity and utilization rate, high requirement for tellurium concentration range, etc., to reduce circulation and Backlog, improve product quality, shorten the effect of electrolysis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

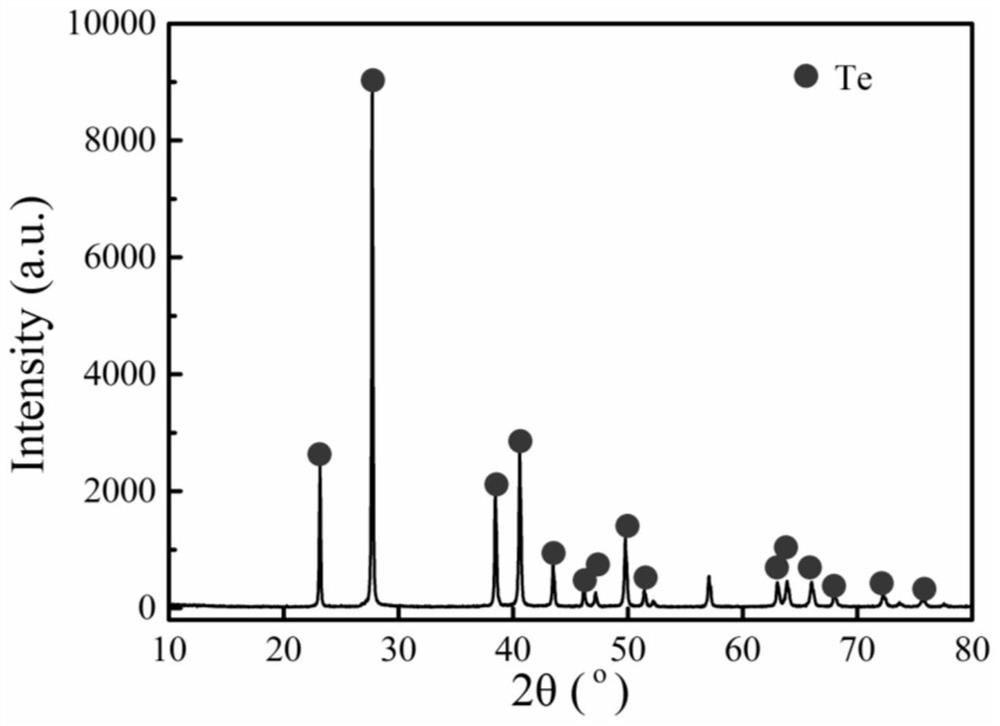

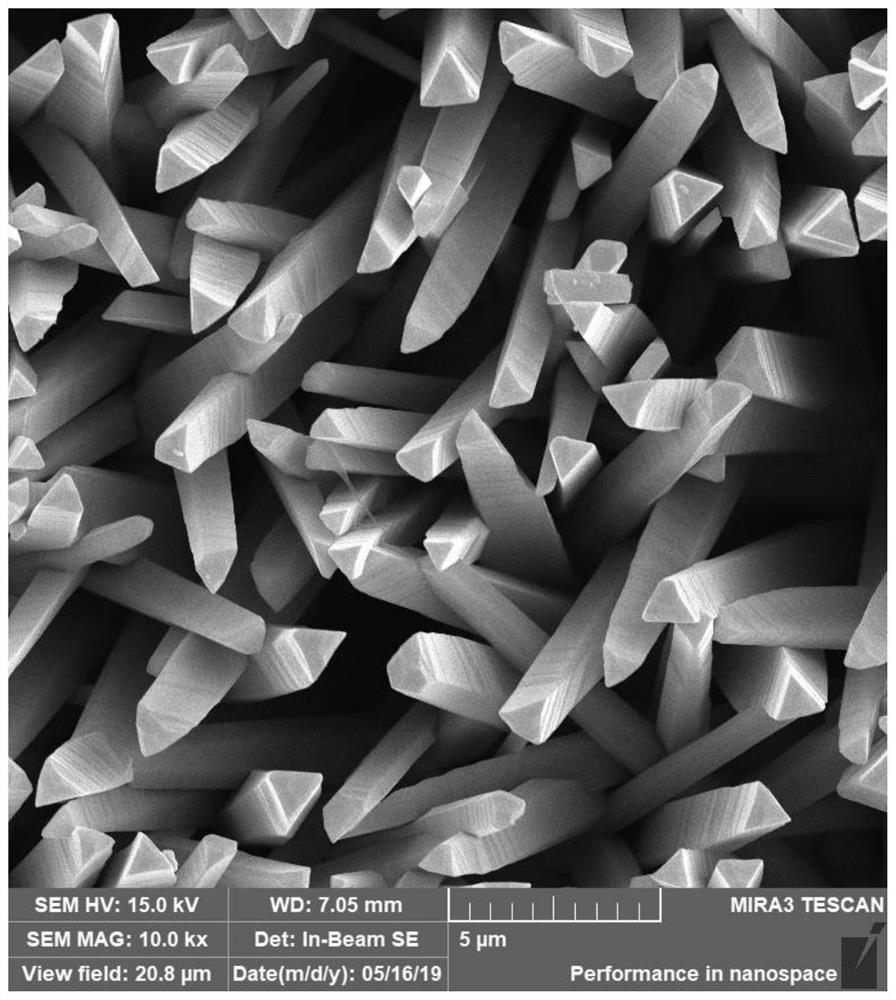

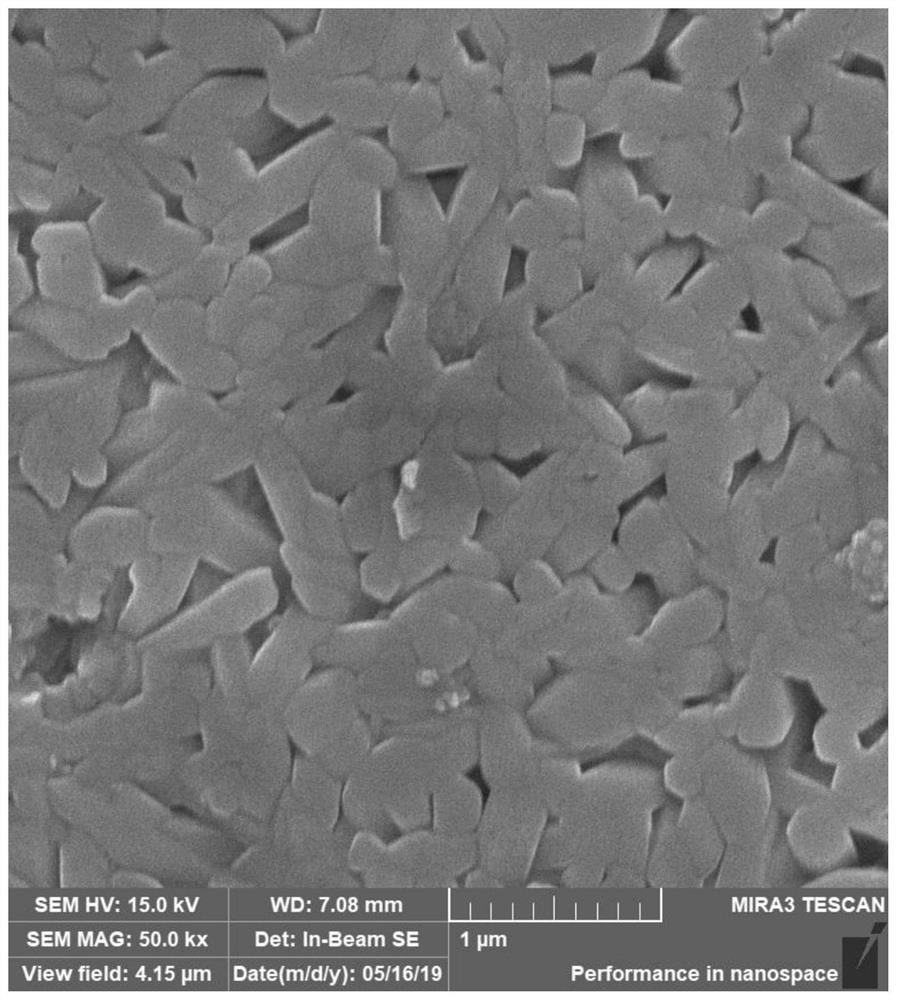

[0062] The method for deep recovery of tellurium by cascaded swirl electrolysis in this embodiment comprises the following steps:

[0063] (1) will refine TeO 2 Add it into a hot NaOH solution to dissolve and make liquid, and prepare an electrolyte solution with a tellurium concentration of 300g / L and a NaOH concentration of 120g / L.

[0064] (2) Then add the electrolyte solution into the swirl electrolysis liquid storage tank-four-necked round bottom flask, heat the electrolyte solution through the electric heating mantle, set the target temperature of the electric heating mantle to 50°C, and turn on the circulating centrifugal pump to control the electrolysis The liquid flow rate is 7L / min, and the air in the circulating pump is emptied. When the temperature of the electrolyte reaches 50°C, turn on the power and control the current density to 400A / m 2 , carry out a section of swirl electrolysis, stop the electrolysis when the tellurium concentration in the electrolyte drops ...

Embodiment 2

[0078] The method for deep recovery of tellurium by cascaded swirl electrolysis in this embodiment comprises the following steps:

[0079] (1) will refine TeO 2 Add it into a hot NaOH solution to dissolve and make liquid, and prepare an electrolyte solution with a tellurium concentration of 265g / L and a NaOH concentration of 110g / L.

[0080] (2) Then add the electrolyte solution into the swirl electrolysis storage tank-four-necked round bottom flask, heat the electrolyte solution through the electric heating mantle, set the target temperature of the electric heating mantle to 45°C, and turn on the circulating centrifugal pump to control the electrolysis The liquid flow rate is 6L / min, and the air in the circulating pump is emptied. When the temperature of the electrolyte reaches 45°C, turn on the power and control the current density to 360A / m 2 , carry out a section of swirl electrolysis, stop the electrolysis when the tellurium concentration in the electrolyte drops to abou...

Embodiment 3

[0085] The method for deep recovery of tellurium by cascaded swirl electrolysis in this embodiment comprises the following steps:

[0086] (1) will refine TeO 2 Add it into a hot NaOH solution to dissolve and make liquid, and prepare an electrolyte solution with a tellurium concentration of 250g / L and a NaOH concentration of 100g / L.

[0087](2) Then add the electrolyte solution into the swirl electrolysis liquid storage tank-four-necked round bottom flask, heat the electrolyte solution through the electric heating mantle, set the target temperature of the electric heating mantle to 40°C, and turn on the circulating centrifugal pump to control the electrolysis The liquid flow rate is 4L / min, and the air in the circulating pump is evacuated. When the temperature of the electrolyte reaches 40°C, turn on the power and control the current density to 300A / m 2 , carry out a section of swirl electrolysis, stop the electrolysis when the tellurium concentration in the electrolyte drops...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com