A copper electrolysis system and method capable of adjusting the ratio of copper to acid

An adjustable technology of copper electrolysis, applied in the chemical industry, can solve the problems of increasing diversification of ore raw materials, restricting the development of copper electrolysis technology, and increasing the chance of cathode long particles, so as to shorten the electrolysis cycle and reduce the occurrence of cathode copper long particles , Improve the quality of cathode copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adopt above-mentioned copper electrolysis system to carry out copper electrolysis operation, concrete steps are as follows:

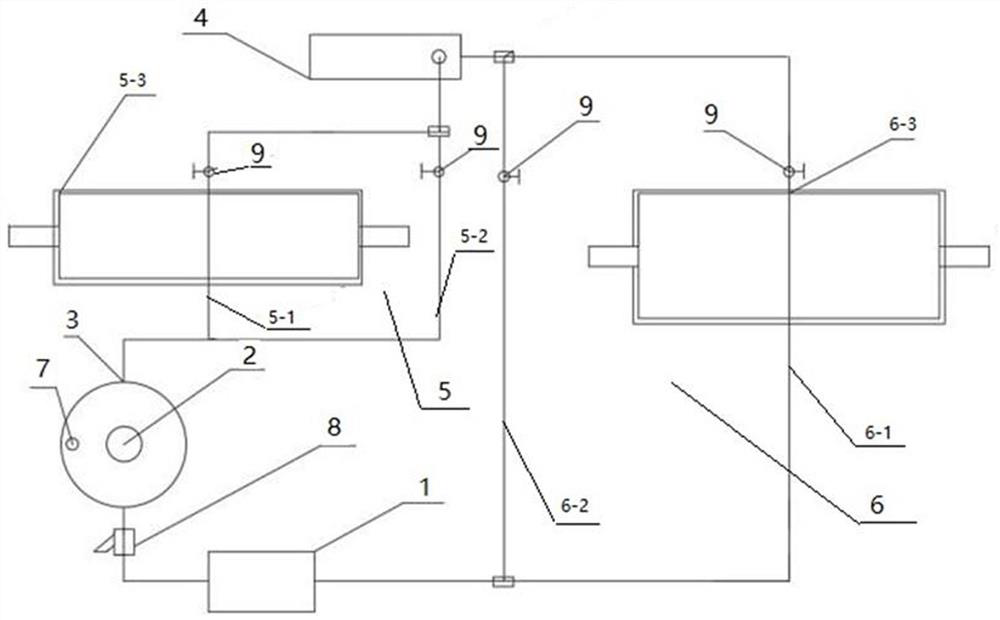

[0025] a. Measure the concentration of copper ions, sulfuric acid and other impurity ions in the electrolyte. The measurement results are shown in Table 1. It can be seen that the concentration of copper ions is 40-50g / L, and the concentration of sulfuric acid is 160-180g / L. Adjust valve 9 to make The first pipeline 5-1 communicates with the third pipeline 6-1, closes the second pipeline 5-2 and the fourth pipeline 6-2, adjusts the magnetic field strength of the first magnetizing device 5-3 to 3-3.5T, and adjusts the magnetic field strength of the first magnetization device 5-3. The magnetic field strength of the second magnetization device 6-3 is 2-3T, the electrolyte is slowly fed from the high tank 3 and filled with the electrolytic tank 1, the temperature control device 7 controls the temperature of the electrolyte at 50°C-65°C, and the circul...

Embodiment 2

[0030] Adopt above-mentioned copper electrolysis system to carry out copper electrolysis operation, concrete steps are as follows:

[0031] a. Measure the concentration of copper ions, sulfuric acid and other impurity ions in the electrolytic solution. The measurement results are shown in Table 2. It can be seen that the concentration of copper ions<40g / L causes the copper acid ratio to be unbalanced. Adjust the valve 9 to make the first pipeline 5-1 and the second pipeline 5-1 The four pipelines 6-2 are connected, the second pipeline 5-2 and the third pipeline 6-1 are closed, the magnetic field strength of the first magnetization device 5-3 is 3-3.5T, and the electrolyte is slowly fed into the high tank 3 and filled The electrolytic cell 1, the temperature control device 7 controls the temperature of the electrolyte to be kept at 50°C-65°C, and the circulation pump 4 is turned on to make the electrolyte circulate and magnetize at a flow rate of 0.4-0.6m / s in the closed loop of...

Embodiment 3

[0036] Adopt above-mentioned copper electrolysis system to carry out copper electrolysis operation, concrete steps are as follows:

[0037] a. Measure the concentration of copper ions, sulfuric acid and other impurity ions in the electrolytic solution. The measurement results are shown in Table 3. It can be seen that when the copper ion concentration> 50g / L causes the copper acid ratio to be unbalanced, adjust the valve 9 to make the first pipeline 5-1 Closed with the fourth pipeline 6-2, the second pipeline 5-2 communicates with the third pipeline 6-1, the magnetic field strength of the second magnetization device 6-3 is 2-3T, and the electrolyte is slowly fed into the liquid from the elevated tank 3 and The electrolytic tank 1 is filled, the temperature control device 7 controls the temperature of the electrolyte to maintain at 50°C-65°C, and the circulation pump 4 is turned on to make the electrolyte circulate and magnetize at a flow rate of 0.4-0.6m / s in the closed loop of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com