Stirring device for processing high-performance anticorrosive and antirust ship coating

A technology of anti-corrosion, anti-rust and stirring device, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc. problems, to achieve the effect of improving the high-performance anti-corrosion and rust-proof effect, ensuring the mixing effect, and improving the stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

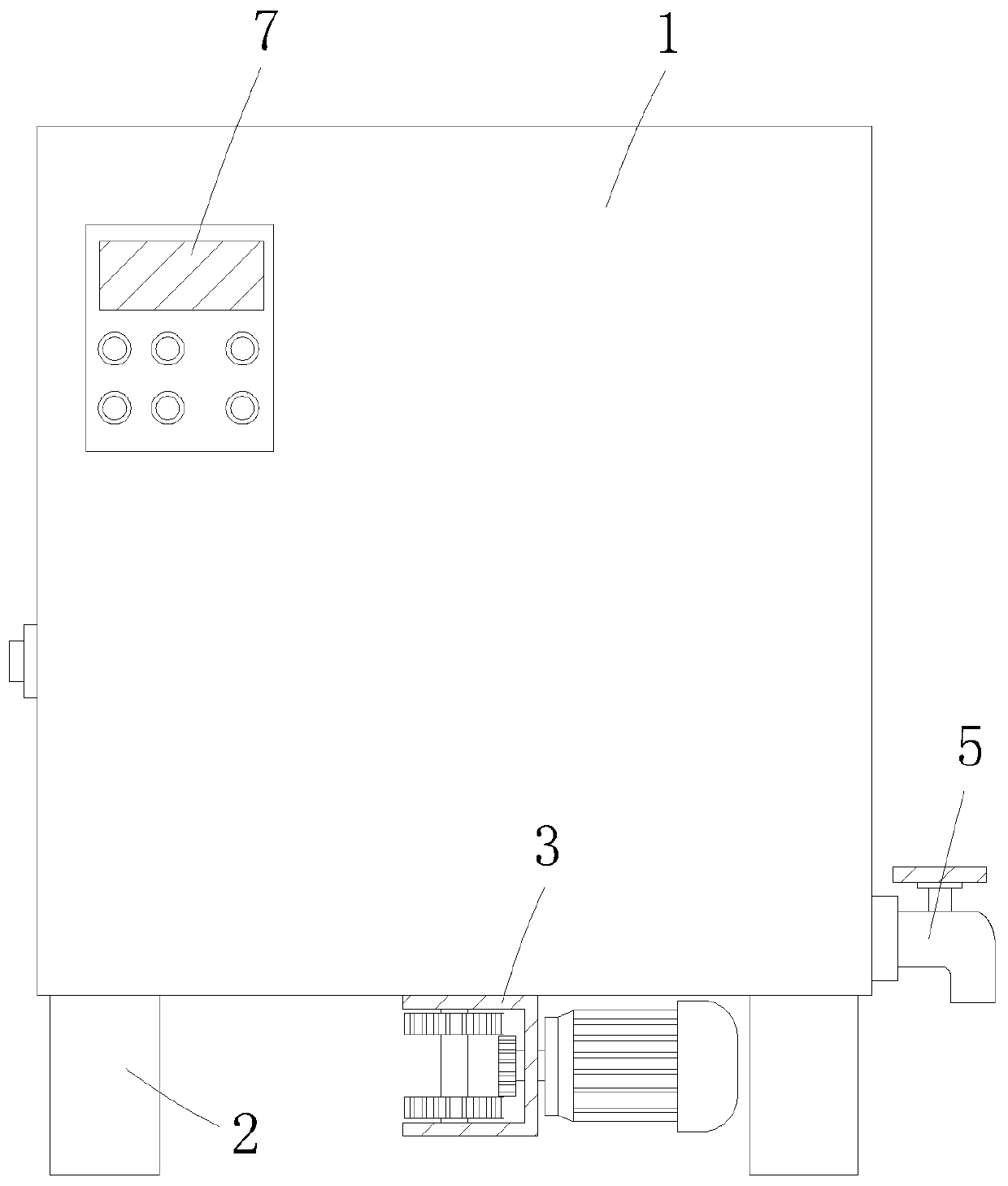

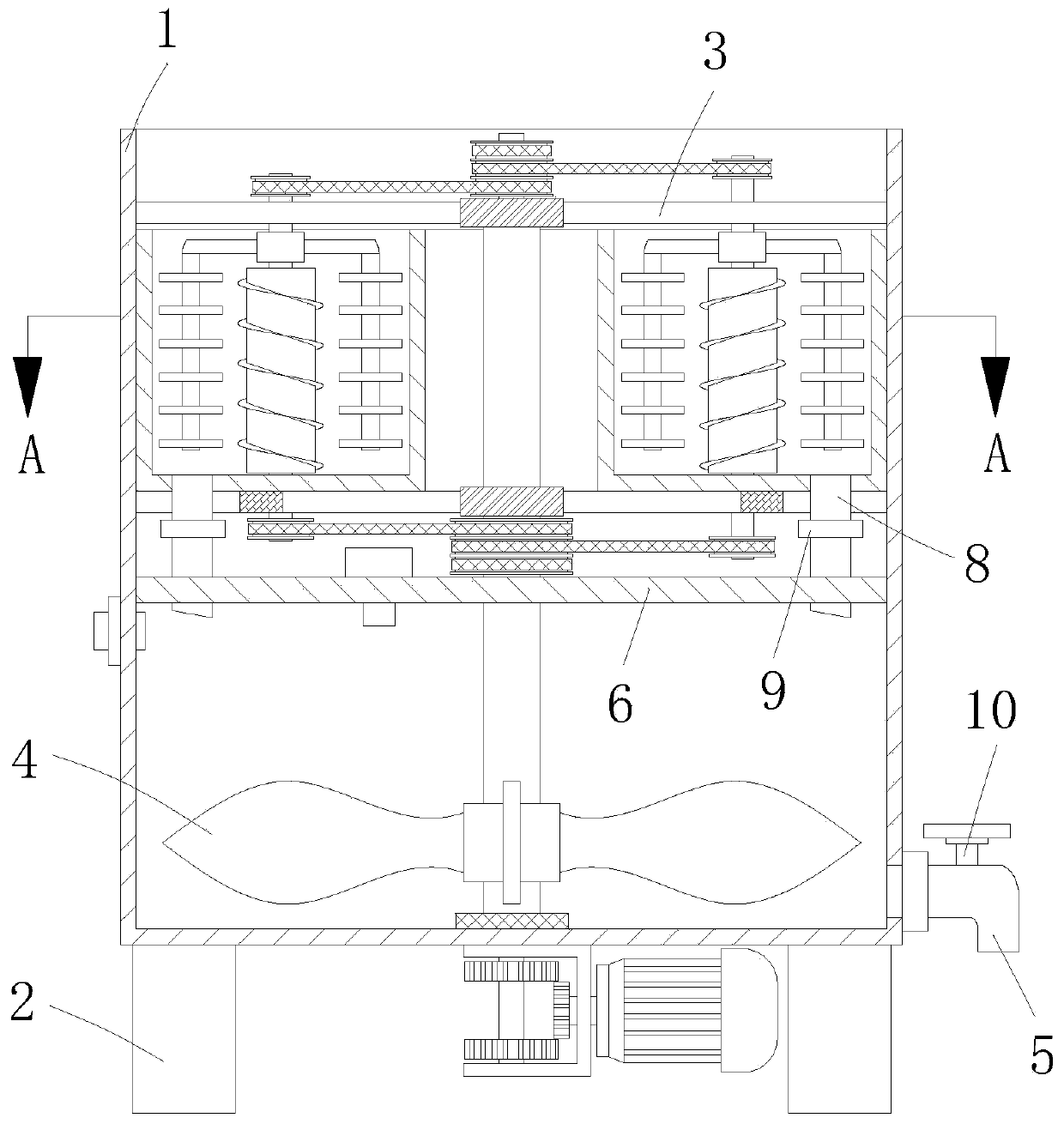

[0041] A high-performance stirring device for anti-corrosion and anti-rust ship paint processing, including a mixing tank body 1 and a plurality of supporting feet installed at the lower end of the mixing tank body 1, the upper surface of the mixing tank body 1 is not closed, and the mixing tank body In the inner cavity of 1, there are in order from top to bottom a mixing mechanism 3, a dividing plate 6 and a mixing mechanism 4, and the dividing plate 6 is horizontally and fixedly installed on the inner wall of the mixing tank body 1, and the dividing plate 6 will stir The inner cavity of barrel body 1 is divided into a main mixing chamber located in the lower part and a sub-mixing chamber located in the upper part. The setting of the partition plate 6 can effectively separate the sub-mixed raw material components and the main mixed raw material components, and protect the sub-mixing chamber. The structure of the lower part of the mechanism 3 improves the anti-corrosion and ant...

Embodiment 2

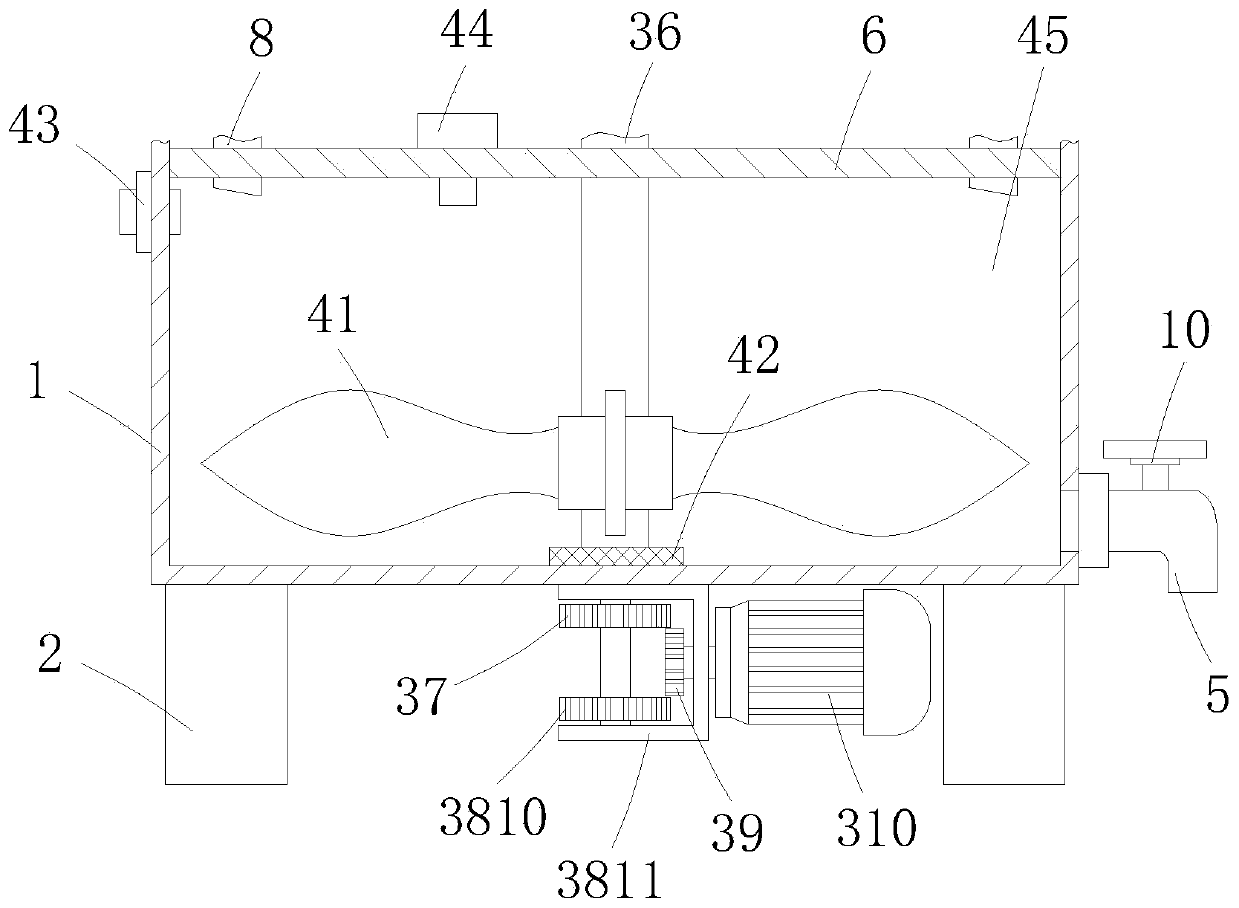

[0058] The difference between this embodiment and embodiment 1 is that, as figure 2 , 4 , 5 and 6, an auxiliary stirring assembly 38 is also provided in the inner cavity of the mixing bucket 31, and the auxiliary stirring assembly 38 includes a mandrel 381 that is inserted in the hollow shaft 36 for rotation, and the lower end of the mandrel 381 Extending to the outer chamber of the hollow shaft 36 and installing the second bevel gear 3810, and the second bevel gear 3810 meshes with the driving bevel gear 39, the upper part of the mandrel 381 extends to the outer chamber of the hollow shaft 36, passing through the three-fork positioning The middle part of the support 382 is also equipped with a three-rail pulley 383, and the three branch bars of the three-fork positioning bracket 382 are fixedly installed on the inner wall of the mixing barrel body 1, and the different tracks of the three-rail pulley 383 are respectively connected with three rails by a transmission belt 384. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com