Preparation method of gas diaphragm

A diaphragm and gas technology, applied in the field of diaphragms, can solve the problems of poor ozone resistance, poor insulation performance, low elasticity, etc., and achieve the effect of solving frequent replacement and saving maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

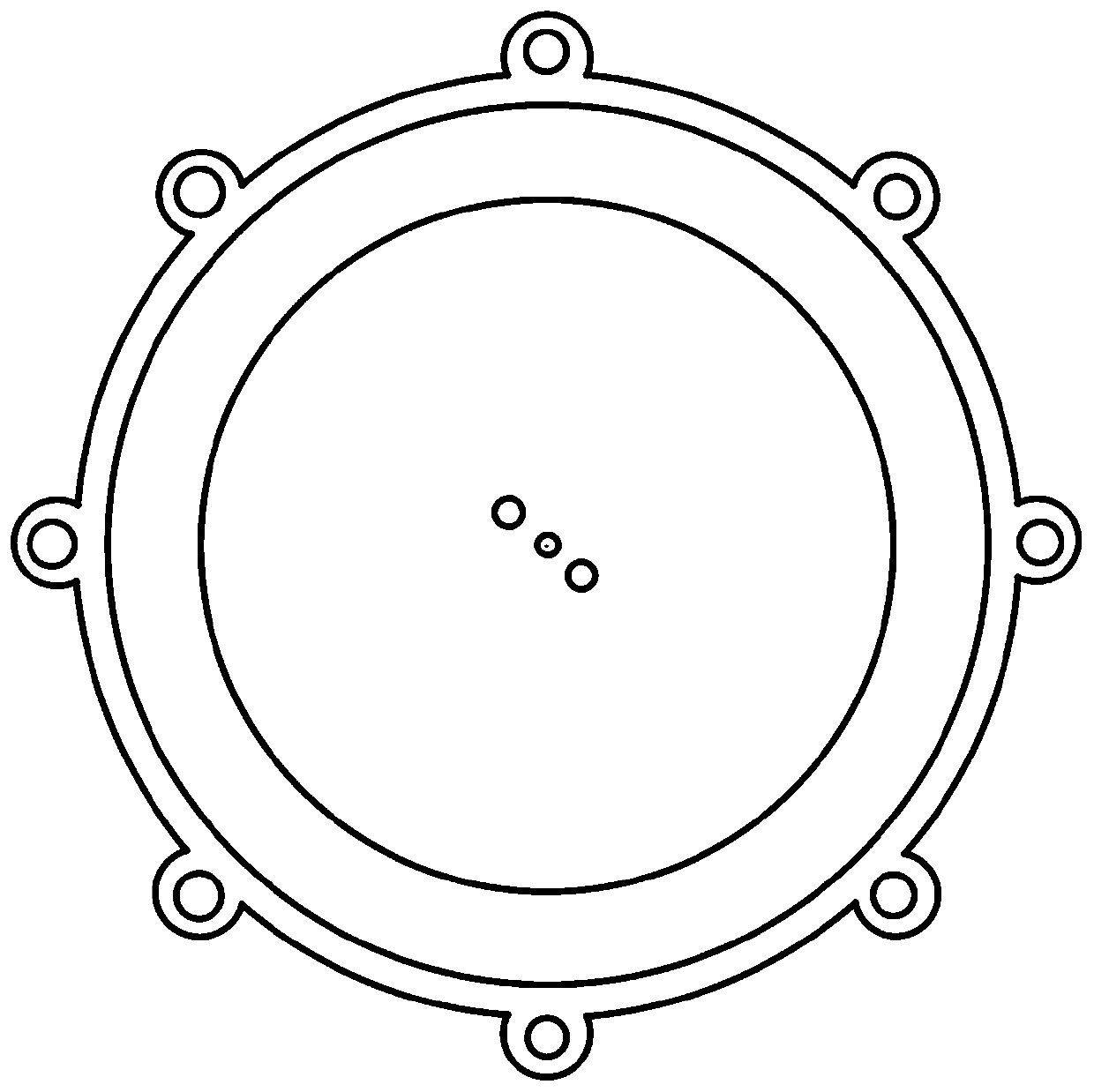

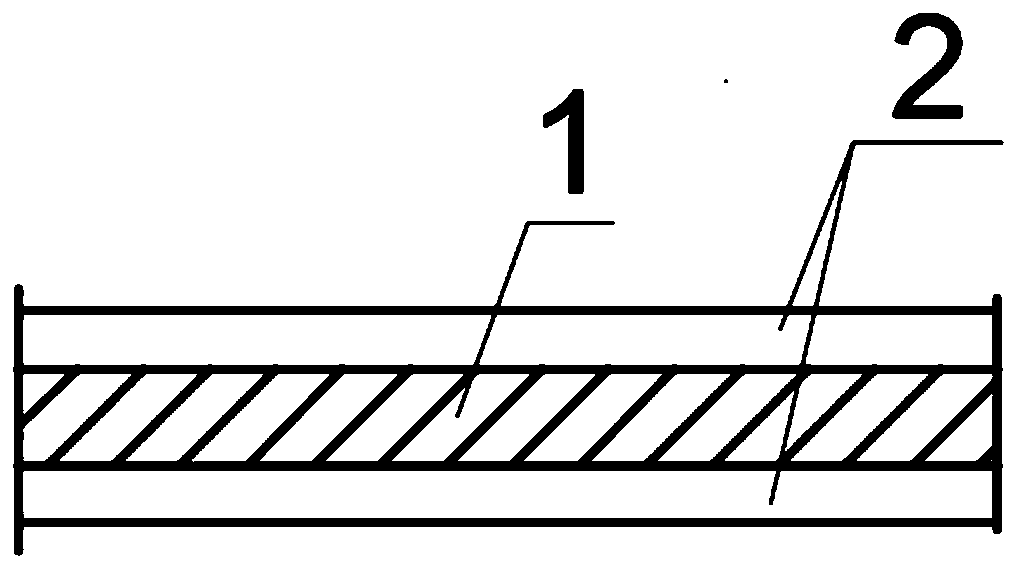

Image

Examples

Embodiment 1

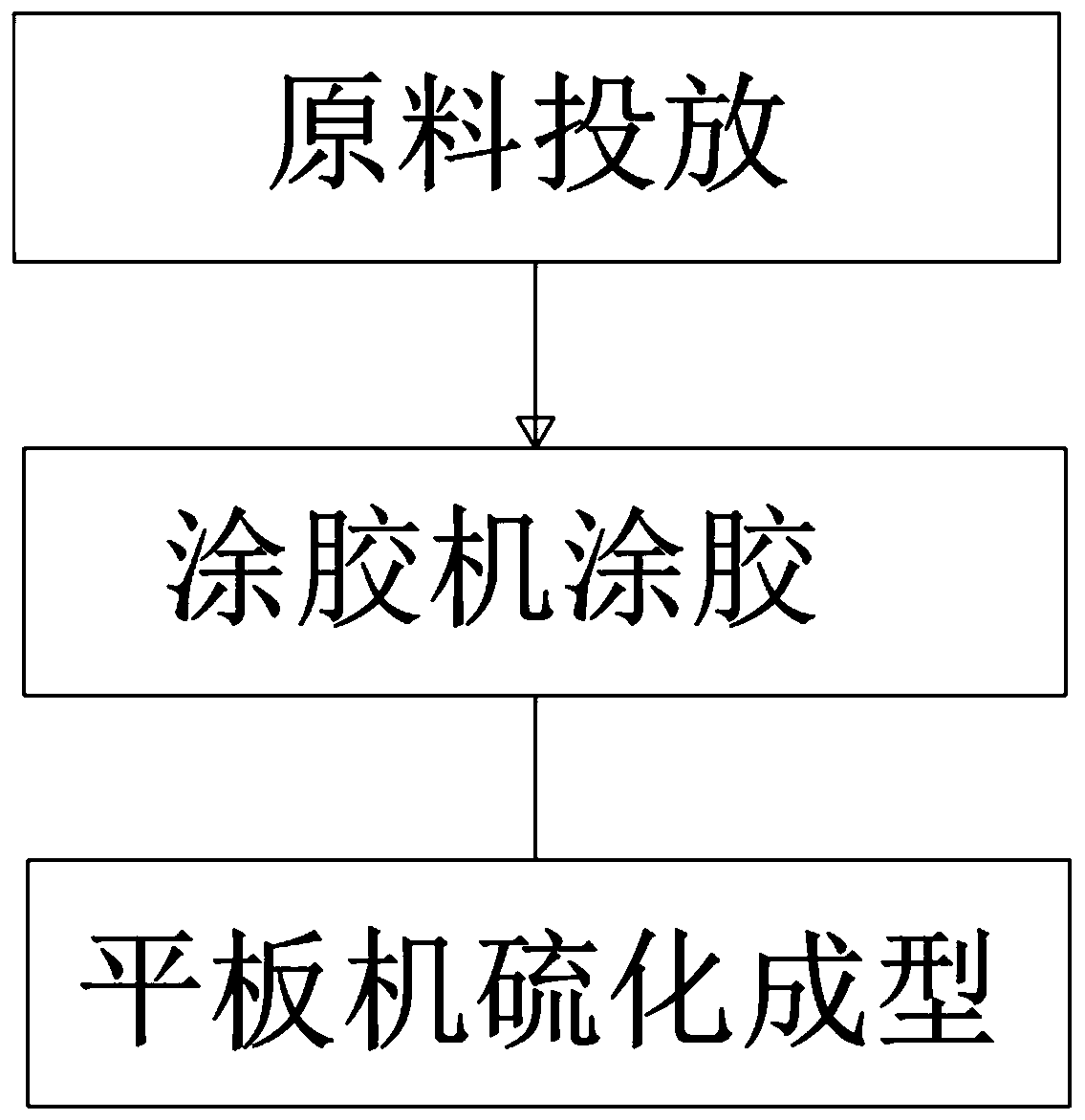

[0019] A method for preparing a gas diaphragm, comprising the steps of:

[0020] 1) Raw material delivery:

[0021] The raw material feeding formula of the gas diaphragm includes nitrile-269000g, polyvinyl chloride 2500g, zinc oxide 400g, stearic acid 50g, aluminum phosphite 50g, antioxidant 100g, carbon black N3309000g, spray carbon black 5000g in parts by weight , light calcium 3000g, dibutyl plasticizer 2500g, accelerator CZ50g, accelerator DM100g, vulcanizing agent 100g, the operator starts mixing after mixing according to the formula;

[0022] 2) Glue coating machine:

[0023] Use nylon woven fabric as the skeleton cloth of the diaphragm, put the blended glue obtained in 1) into the glue applicator, and coat the blended glue on the upper and lower sides of the nylon skeleton cloth, when the coated two sides are blended When the glue reaches the required thickness, stop the machine to dry, and use a clean pad to send the semi-finished product to the semi-finished worksho...

Embodiment 2

[0029] A method for preparing a gas diaphragm, comprising the steps of:

[0030] 1) Raw material delivery:

[0031] The raw material feeding formula of the gas diaphragm is in parts by weight, including nitrile-2611000g, polyvinyl chloride 3500g, zinc oxide 600g, stearic acid 150g, aluminum phosphite 100g, antioxidant 150g, carbon black N33011000g, spray carbon black 6000g , 4000g of light calcium, 3500g of dibutyl plasticizer, 150g of accelerator CZ, 150g of accelerator DM, and 150g of vulcanizing agent. After the operator measures and mixes according to the formula, start mixing;

[0032] 2) Glue coating machine:

[0033] Use nylon woven fabric as the skeleton cloth of the diaphragm, put the blended glue obtained in 1) into the glue applicator, and coat the blended glue on the upper and lower sides of the nylon skeleton cloth, when the coated two sides are blended When the glue reaches the required thickness, stop the machine to dry, and use a clean pad to send the semi-fi...

Embodiment 3

[0039] A method for preparing a gas diaphragm, comprising the steps of:

[0040] 1) Raw material delivery:

[0041] The feeding formula of the gas diaphragm raw material is in parts by weight, including nitrile-2610000g, polyvinyl chloride 3000g, zinc oxide 500g, stearic acid 100g, aluminum phosphite 100g, antioxidant 130g, carbon black N3301000g, spray carbon black 5500g , 3600g of light calcium, 3000g of dibutyl plasticizer, 100g of accelerator CZ, 120g of accelerator DM, and 130g of vulcanizing agent. After the operator measures and mixes according to the formula, start mixing;

[0042] 2) Glue coating machine:

[0043] Use nylon woven fabric as the skeleton cloth of the diaphragm, put the blended glue obtained in 1) into the glue applicator, and coat the blended glue on the upper and lower sides of the nylon skeleton cloth, when the coated two sides are blended When the glue reaches the required thickness, stop the machine to dry, and use a clean pad to send the semi-fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com