Composition of door closer oil

A door closer oil, oil composition technology, applied in lubricating composition, petroleum industry and other directions, can solve the problems of high shear loss rate, unsatisfactory viscosity retention ability, etc., and achieve good extreme pressure and wear resistance, high resistance The effect of grinding, high and antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

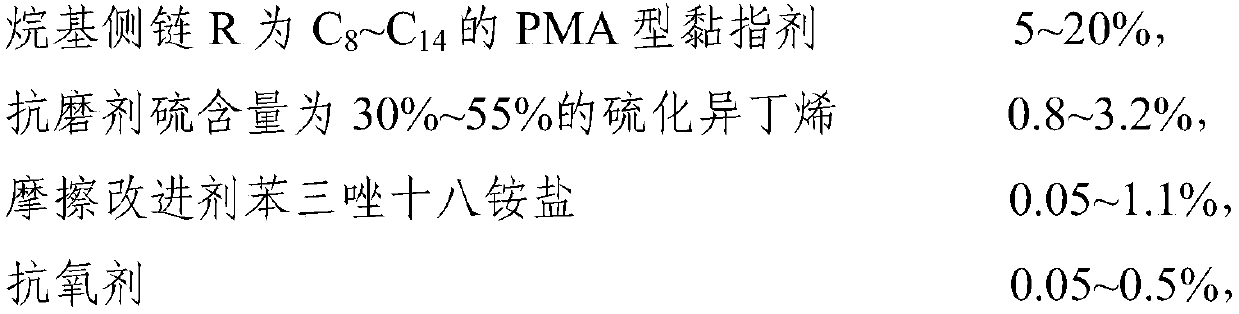

Method used

Image

Examples

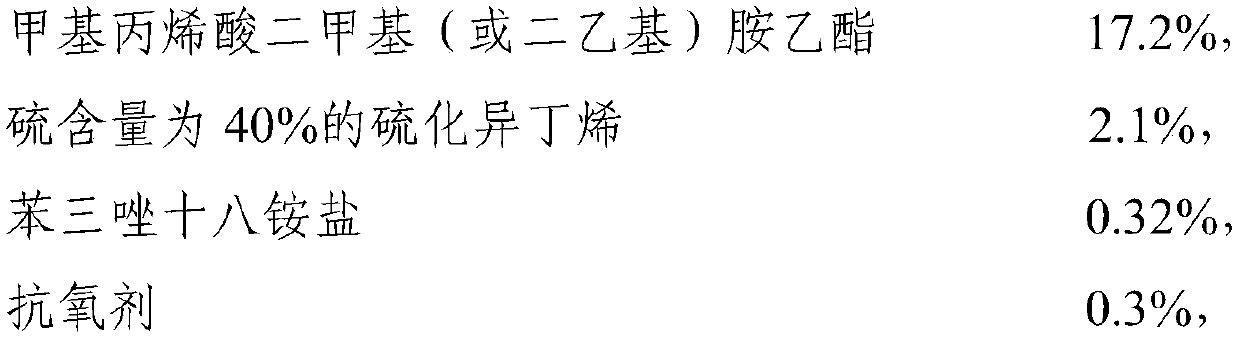

Embodiment 1

[0022] This embodiment provides a door closer oil composition, the door closer oil composition is composed of the following components in percentage by weight: the PMA type viscosity index agent dimethyl methacrylate whose alkyl side chain R is C14 Base (or diethyl) aminoethyl ester 17.2%, sulfurized isobutylene 2.1% with a sulfur content of 40%, benzotriazole octadecyl ammonium salt 0.32%, 2,6 di-tert-butylphenol and dioctyl diphenylamine according to 1: The compounding ratio of 2 is 0.3%, the pour point depressant polytetradecyl methacrylate is 0.35%, the anti-emulsifier ethylene glycol ester is 0.31%, methyl silicone oil is 0.005%, the base oil YU4 is 23.1%, PAO2 for the margin.

[0023] Prepared by conventional methods in the art.

Embodiment 2

[0025] This embodiment provides a door closer oil composition, the door closer oil composition is composed of the following components in percentage by weight: the PMA type viscosity index agent dimethyl methacrylate whose alkyl side chain R is C14 Base (or diethyl) amino ethyl ester 5%, sulfur content of 30% isobutylene 3.2%, benzotriazole octadecyl ammonium salt 0.05%, 2,6 di-tert-butylphenol and dioctyl diphenylamine according to 1: The ratio of 3 is 0.05%, the pour point depressant polytetradecyl methacrylate is 1.2%, the anti-emulsifier ethylene glycol ester is 0.012%, the methyl silicone oil is 0.0002%, the base oil PAO4 is 21.3%, II2 for the margin.

[0026] Prepared by conventional methods in the art.

Embodiment 3

[0028] This embodiment provides a door closer oil composition, the door closer oil composition is composed of the following components in weight percentage: PMA type viscosity index agent 2-methyl- 20% of 5-vinylpyridine, 0.8% of sulfurized isobutylene with a sulfur content of 55%, 1.1% of benzotriazole octadecyl ammonium salt, 2,6 di-tert-butylphenol and dioctyl diphenylamine in a ratio of 3:1 0.5%, pour point depressant polytetradecyl methacrylate 1.2%, anti-emulsifier ethylene glycol ester 1.0%, methyl silicone oil 0.008%, base oil S4 35.4%, NS3 the balance.

[0029] Prepared by conventional methods in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com