A modified positive electrode material and its preparation method and application

A positive electrode material and modification technology, applied in the field of modified positive electrode materials and its preparation, can solve problems such as unfavorable material application, uneven surface coverage, and reduced material capacity, and achieve improved cycle performance and high-temperature storage capacity retention rate, surface Improvement of stability and storage stability and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

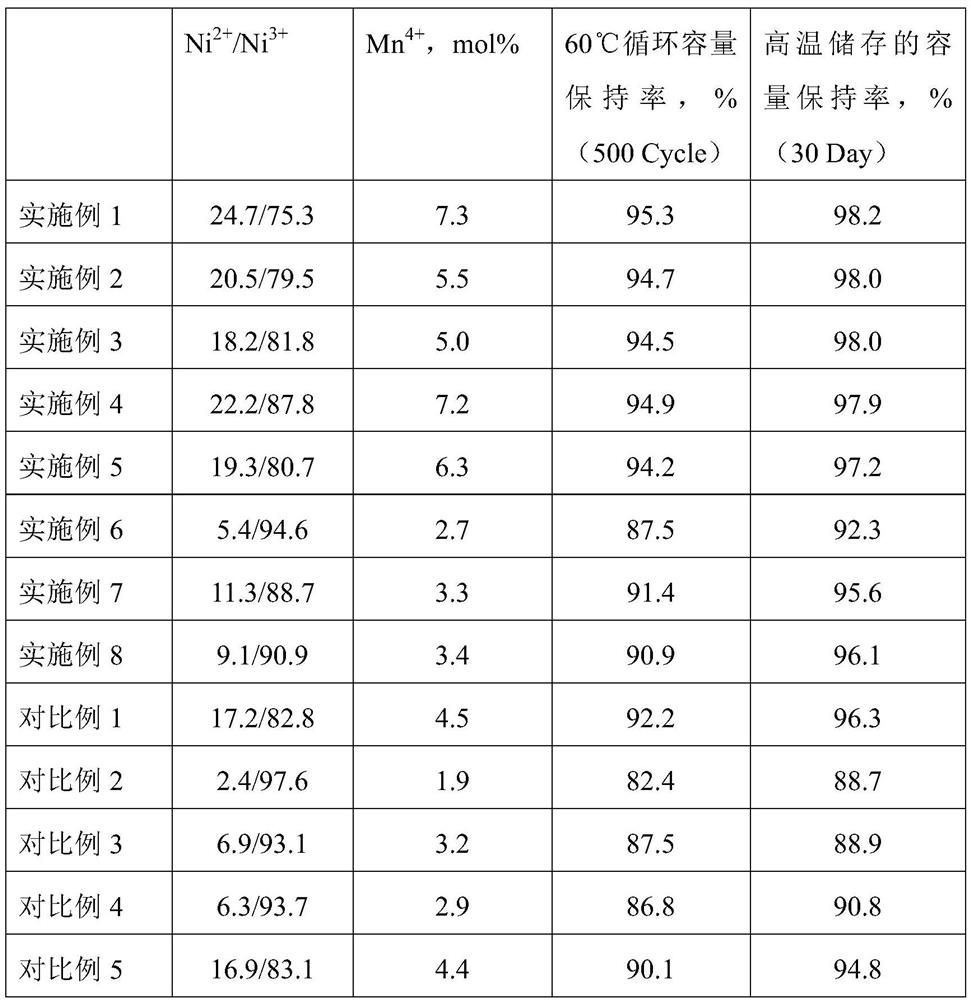

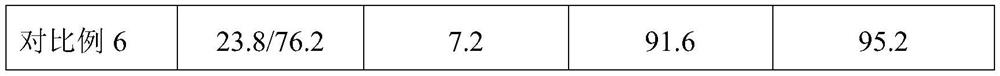

Examples

Embodiment 1

[0050] The positive electrode material used in this example is LiNi 0.6 Co 0.2 Mn 0.2 O 2 ;

[0051] The preparation method of the modified cathode material:

[0052] (1) uniformly mixing modifier and high-nickel positive electrode material in high-mixer, obtain mixture, described modifier is lithium citrate, and the mass ratio of described modifier and high-nickel positive electrode material is 5: 95;

[0053] (2) The mixture obtained in step (1) is heat-treated at 250° C. for 5h in an air atmosphere, and the flow rate of the oxygen atmosphere is 0.4m 3 / h / kg, followed by cooling to obtain the modified cathode material.

Embodiment 2

[0055] The difference between this example and Example 1 is that lithium citrate is replaced with lithium acetate of equal quality, and other conditions are exactly the same as those in Example 1.

Embodiment 3

[0057] The difference between this example and Example 1 is that lithium citrate is replaced with lithium oxalate of the same quality, and other conditions are exactly the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com