A kind of manufacturing method of bluetooth earphone battery

A technology of bluetooth earphones and manufacturing methods, applied in the field of batteries, capable of solving problems such as high internal resistance, heat generation, and large charging current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

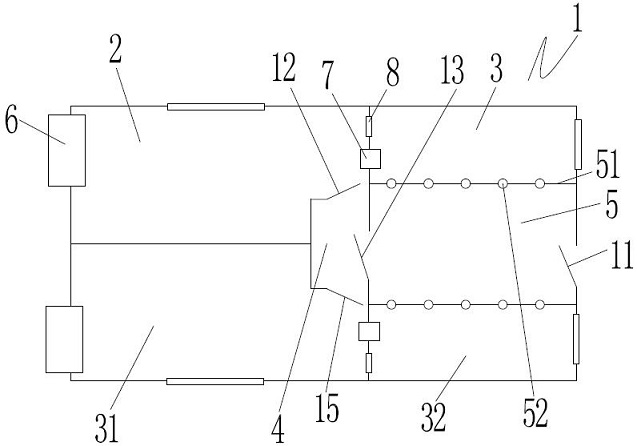

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] A method for making a battery for a Bluetooth earphone, comprising the following steps:

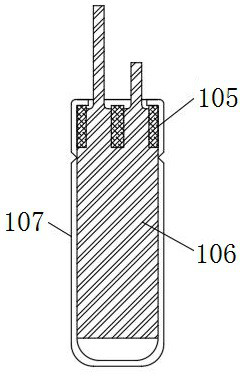

[0035] S1: Prepare the core pack 106, including the following steps S11~S15;

[0036] S11: Apply conductive coating, apply conductive paste on the surface of aluminum foil and copper foil, the thickness of the coating is 1~3 microns, the conductive paste is NMP with a mass percentage of 90~97.2%, and the mass percentage is 2.8%~ 10% PVDF, carbon black and multi-walled carbon nanotubes, wherein the weight ratio of PVDF, carbon black and multi-walled carbon nanotubes is 1:50:5;

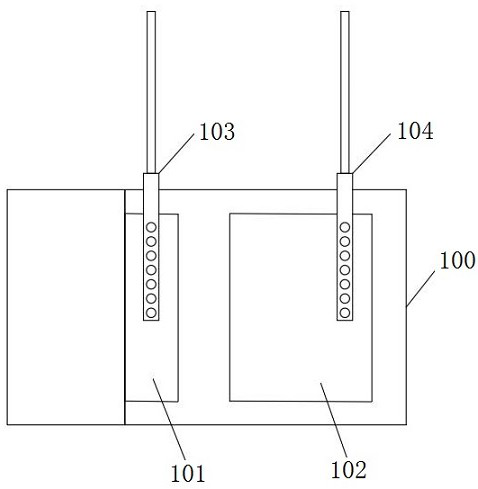

[0037] S12: coating, the positive electrode slurry is coated on the aluminum foil to prepare the positive electrode sheet 101, and the negative electrode slurry is coated on the copper foil to prepare the negative electrode sheet 102. The positive electrode slurry includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com