Manufacturing method of Bluetooth headset battery

A technology of bluetooth earphones and manufacturing methods, applied in the field of batteries, capable of solving problems such as high internal resistance, heat generation, and large charging current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

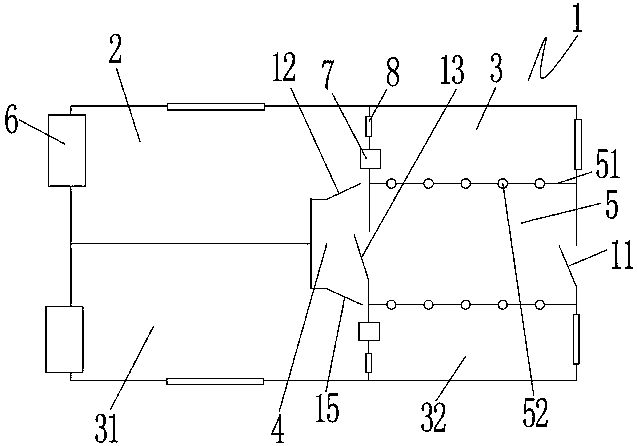

[0033] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0034] A method for manufacturing a Bluetooth headset battery includes the following steps:

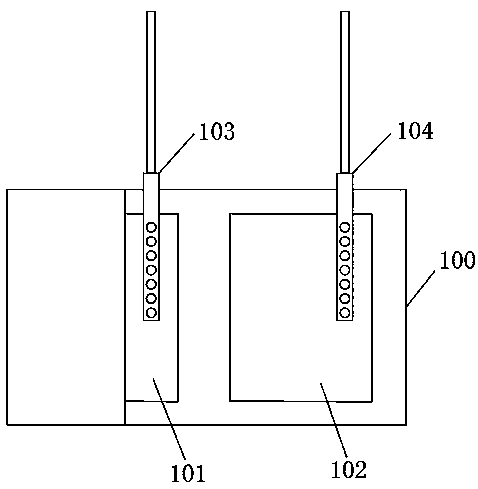

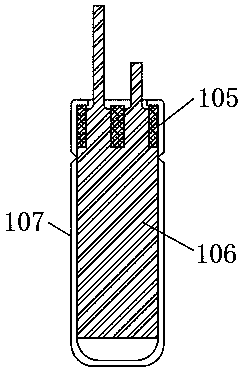

[0035] S1: preparing the core pack 106, including the following steps S11 to S15;

[0036] S11: Apply conductive coating, apply conductive paste on the surface of aluminum foil and copper foil, the thickness of the coating is 1~3 microns, the conductive paste is made of 90-97.2% NMP by mass and 2.8% by mass. 10% PVDF, carbon black and multi-walled carbon nanotubes, the weight ratio of PVDF, carbon black, and multi-walled carbon nanotubes is 1:50:5;

[0037] S12: Coating. The positive electrode slurry is coated on aluminum foil to prepare a positive pole piece 101, and the negative electrode slurry is coated on a copper foil to prepare a negative pole piece 102. The positive electrode slurry includes positive electrode active materials, adhesives, Conductive agent and solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com