Horizontal flow precipitation water collecting device

A water collection device and advection sedimentation technology, which is applied in the direction of sedimentation separation, feeding/discharging device of sedimentation tank, sedimentation tank, etc., can solve the problems of reduced sedimentation area, high load on the weir, troublesome cleaning, etc., and achieve the improvement Effects of water production capacity, reduction of catchment area, and increase in load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

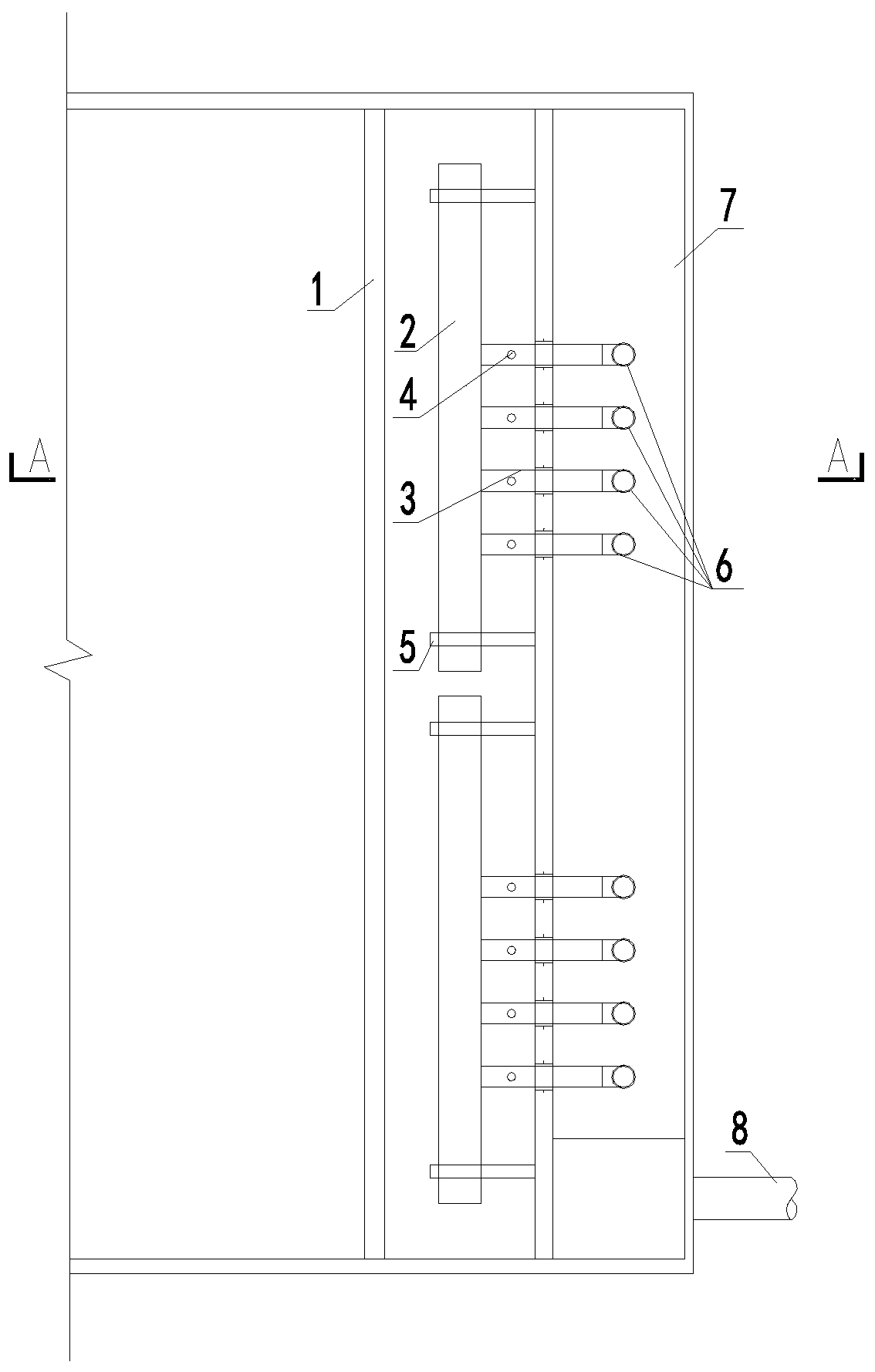

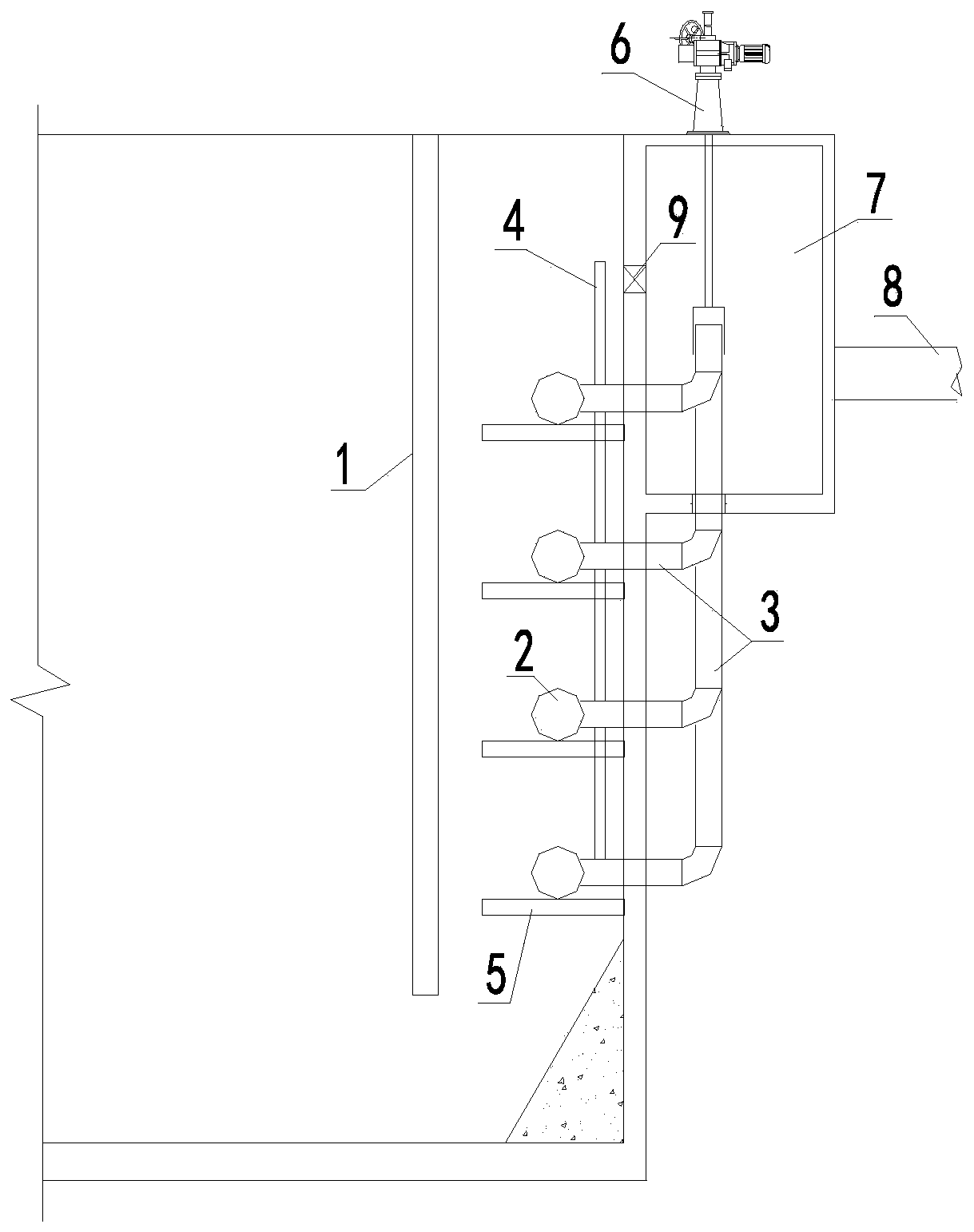

[0022] Such as figure 1 , figure 2 and Figure 5 As shown, the present invention provides an advection sedimentation water collection device, comprising a device body and an outlet channel 7, the outlet channel 7 is used to collect water, the device body is a cuboid structure, and the outlet channel 7 is arranged on the On the outer wall of the device body, a rectification wall 1 and a water collection assembly are arranged in the device body, and the rectification wall 1 can better rectify the hydraulic flow state, wherein the water collection assembly includes a perforated water collection pipe 2, a water outlet pipe 3 and the water outlet control gate 6, the perforated water collection pipe 2 is arranged in layers, and considering the hydraulic balance, the service area of a single pipe does not exceed 5m×0.5m, and the perforated water collection pipe 2 is connected to one end of the water outlet pipe 3, so The other end of the outlet pipe 3 extends into the outlet cha...

Embodiment 2

[0024] This embodiment is basically the same as the first embodiment, and only the differences will be described below.

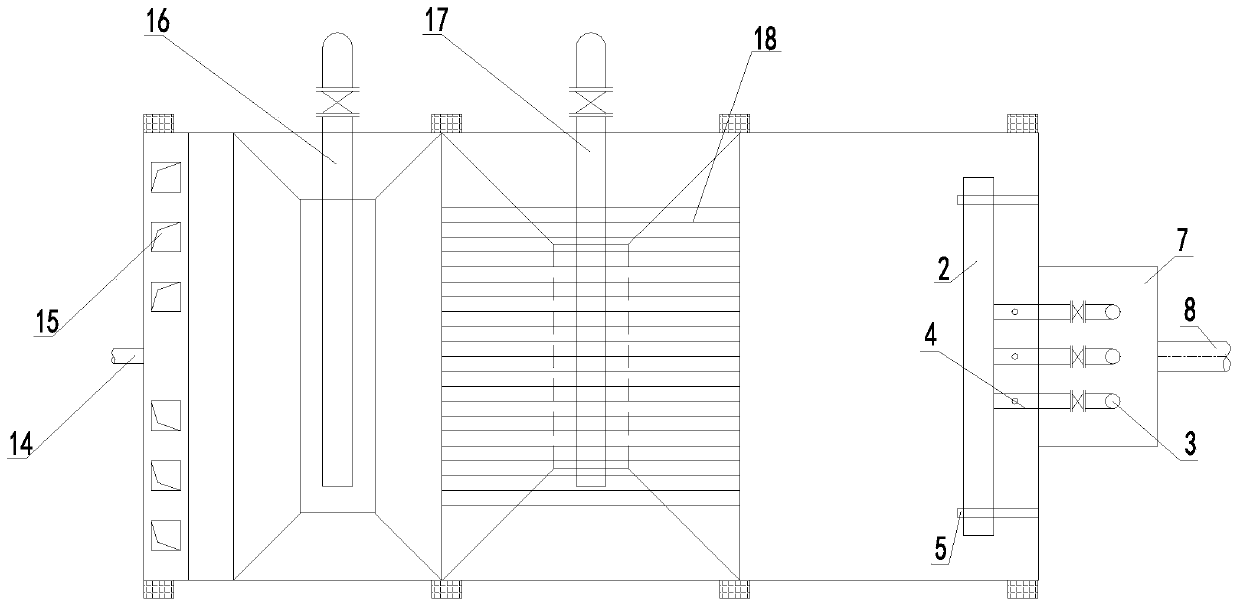

[0025] Such as image 3 and Figure 4 As shown, in this embodiment, the device body is different from that in Embodiment 1. The device body in this embodiment includes a water distribution area 10, a transition area 11, a sedimentation area 12 and a water collection area 13. The water replenishment area A water inlet 14 is provided on the side wall of 10, and a water distribution tank 15 is provided at the position of the water inlet 14 in the water distribution area 10, and a hole groove is opened at the lower end of the water distribution tank 15, and the water supply area 10 and the transition area 12 A screen grid is set, and the transition zone 11 is used to preliminarily settle the sediment in the water body. The lower end of the transition zone 11 is an inverted truncated pyramid structure, and the first sewage pipe 16 is set in the structure, so A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com