Method for repairing heavy metal contaminated soil

A technology for polluting soil and heavy metals, applied in the field of soil treatment, can solve the problems of complex operation, long time, heavy workload, etc., and achieve the effects of simple construction operation, short processing time, and reduced mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

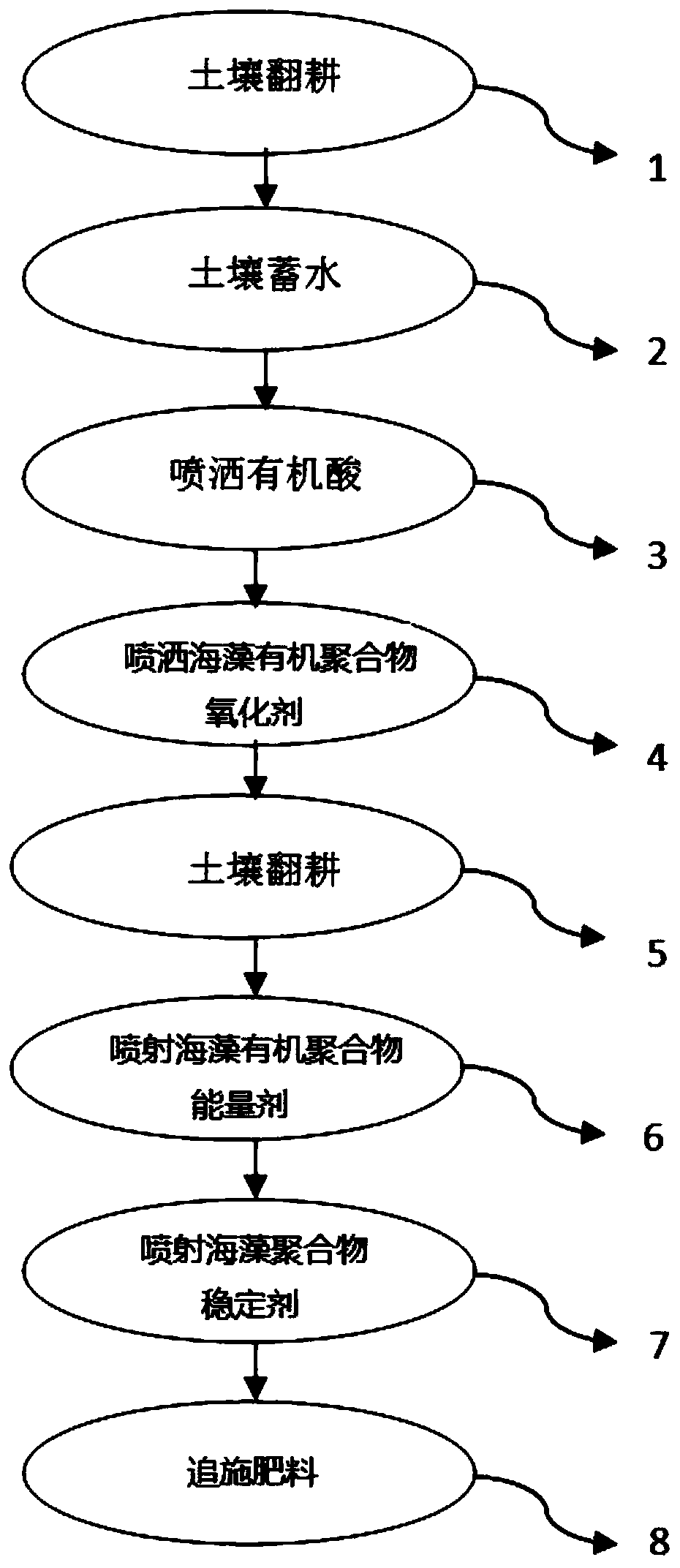

[0043] The present embodiment provides a method for remediating heavy metal-contaminated soil, said method comprising the following steps:

[0044] (1) Soil pretreatment: introduce irrigation water to cover the heavy metal-contaminated farmland soil, the irrigation water depth is 5 cm, and turn it into muddy soil by repeated plowing;

[0045] (2) Preliminary repair: Spray oxalic acid and seaweed organic polymer oxidant into the muddy soil formed in step (1) respectively, plow it again and again, leave it for 72 hours to form a preliminary repair soil, and repeat the above preliminary repair process 4 times;

[0046] (3) Further repair: keep the soil surface water depth 5 cm, add seaweed organic polymer energy agent to the preliminary repair soil formed in step (2), plow it repeatedly, let stand for 100 minutes, make the soil and water weakly alkaline, pH is 7.5;

[0047] (4) Stabilization and topdressing: after further restoration in step (3), let stand for 6.5 days, and top...

Embodiment 2

[0049] The present embodiment provides a method for remediating heavy metal-contaminated soil, said method comprising the following steps:

[0050] (1) Soil pretreatment: cofferdam water storage, introduction of irrigation water to cover the heavy metal-contaminated paddy field soil, the surface water depth is 5 cm, after the water storage is completed, the pH and ORP indicators of the water and soil are tested, and the results show that: water and soil The pH of the rice field is 5.5, and the ORP is in line with the normal ORP index of the soil; repeated plowing 3 times to ensure that the plowing depth is 40 cm to make it into a muddy soil; if mechanical plowing is used, the plowing time of each mu of paddy field shall not be less than 30 minutes;

[0051] (2) Preliminary restoration: The total volume of the treated soil is obtained by multiplying the area of the treated soil by the depth of soil plowing (excluding the surface water storage depth), and the amount of organic...

Embodiment 3

[0056] Such as figure 1 As shown, the present embodiment provides a method for remediating heavy metal-contaminated soil, the method comprising the following steps:

[0057] (1) Soil pretreatment: cofferdam water storage, introduction of irrigation water to cover the heavy metal-contaminated paddy field soil, the surface water depth is 5 cm, after the water storage is completed, the pH and ORP indicators of the water and soil are tested, and the results show that: water and soil The pH of the rice field is 5.5, and the ORP is in line with the normal ORP index of the soil; repeated plowing 3 times to ensure that the plowing depth is 40 cm to make it into a muddy soil; if mechanical plowing is used, the plowing time of each mu of paddy field shall not be less than 30 minutes;

[0058] (2) Preliminary restoration: The total volume of the treated soil is obtained by multiplying the area of the treated soil by the depth of soil plowing (excluding the surface water storage depth)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com