Dealkylation method for carbon dioxide containing hydrocarbon impurities

A carbon dioxide and hydrocarbon removal technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of wasting energy, increasing costs, and not being able to completely remove hydrocarbons, so as to reduce energy consumption, reduce heating energy consumption, The effect of reducing subsequent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

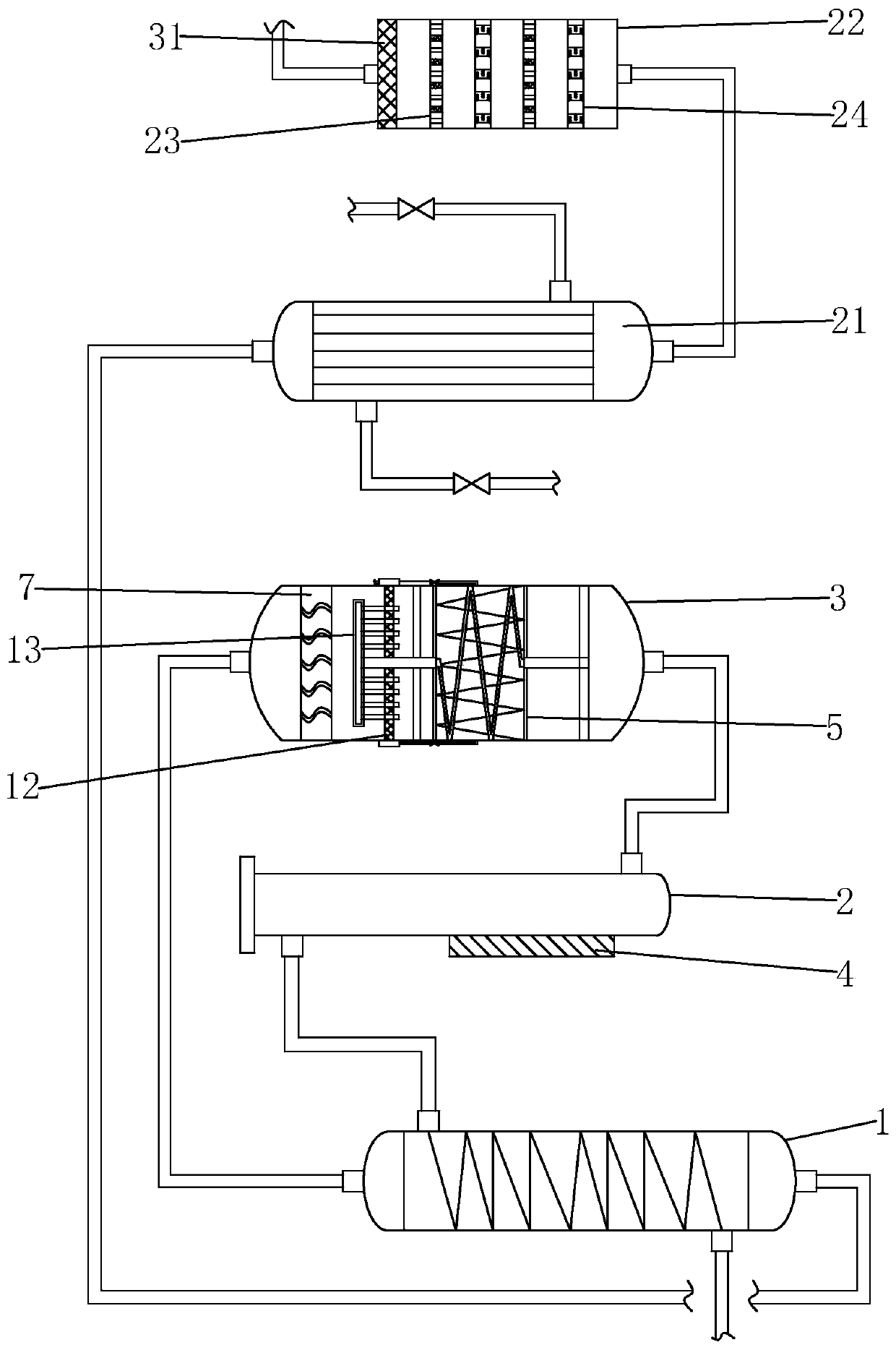

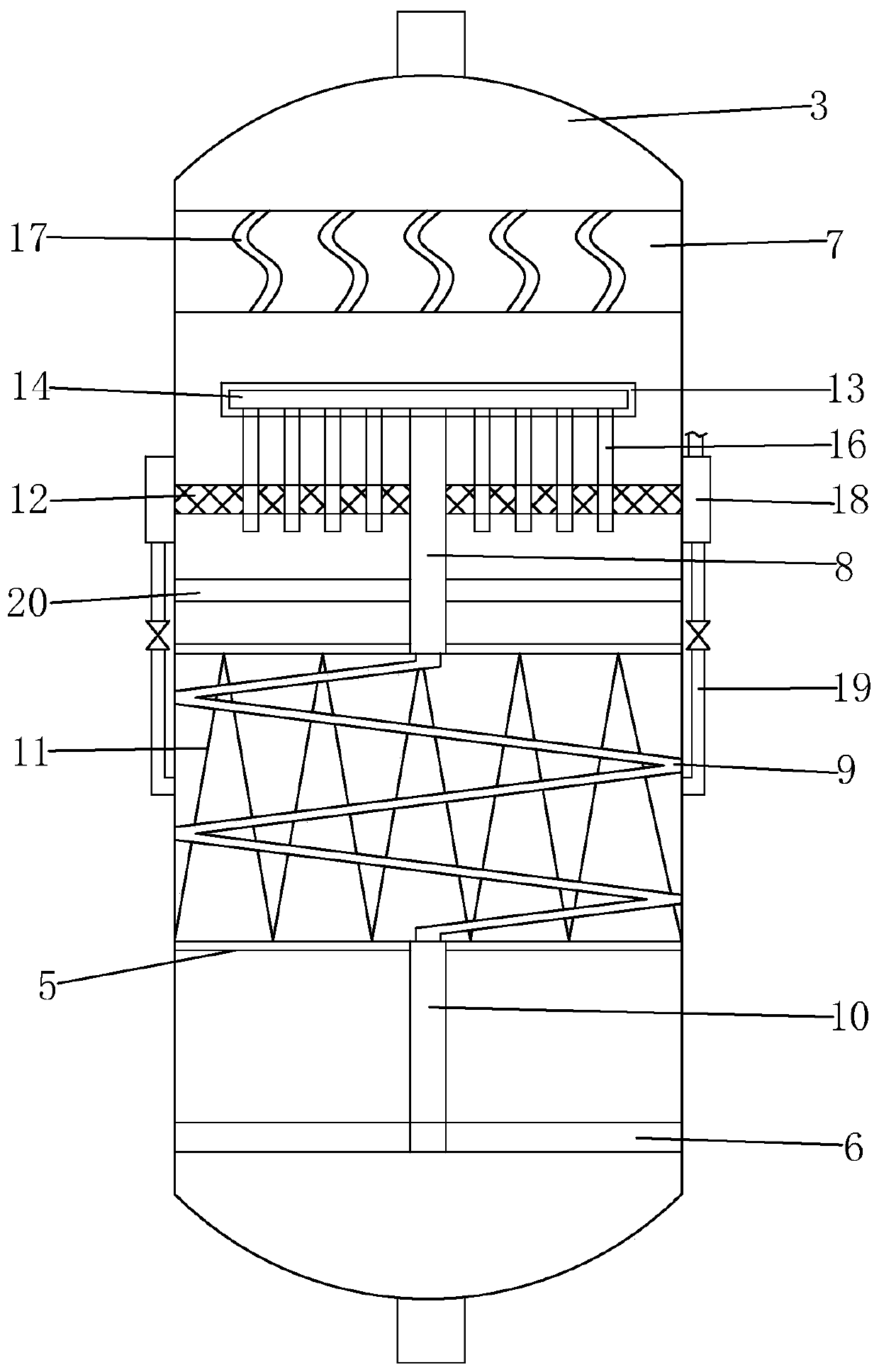

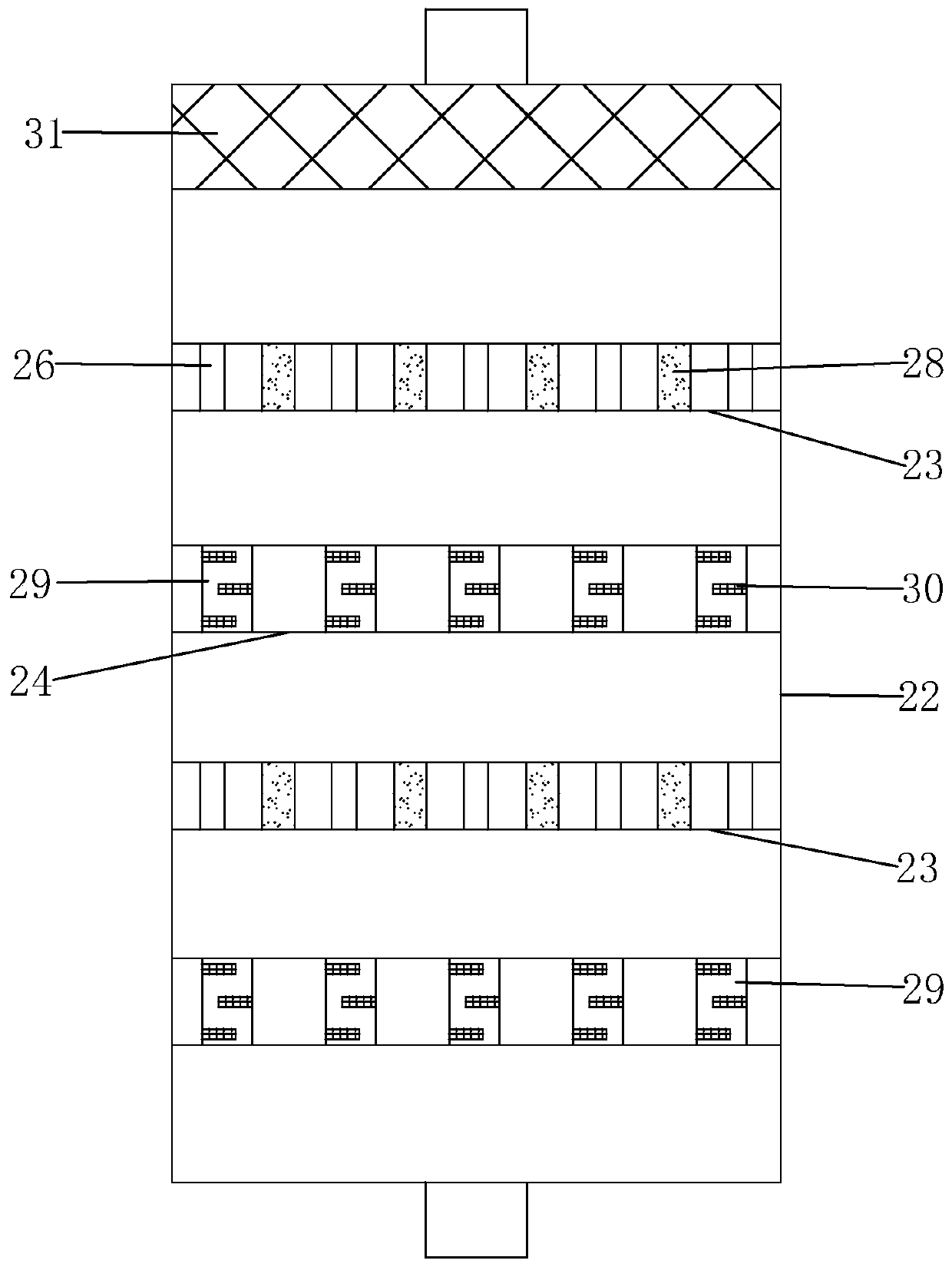

[0035] Such as Figure 1 to Figure 6 Shown, be a kind of method for the dehydrocarbonation of carbon dioxide containing hydrocarbon impurity of the present invention, comprise the steps:

[0036] (a) Preheating the raw material gas: the carbon dioxide raw material gas first enters the coiled pipe preheater 1 for preheating, then enters the dehydrocarbon electric heater 2 for heating, and then enters the bottom of the dehydrocarbon reaction tower 3 after heating, so that the carbon dioxide raw material The temperature of the gas is raised to meet the requirements of the dehydrocarbonation reaction temperature. The outer wall of the dehydrogenation electric heater 2 is provided with an electric heating cable 4, and the electric heating cable 4 plays the role of heat compensation, so as to keep the heating temperature within the set range, automatic adjustment, energy saving and convenience.

[0037] The dehydrogenation reaction tower 3 is respectively provided with a coiled hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com