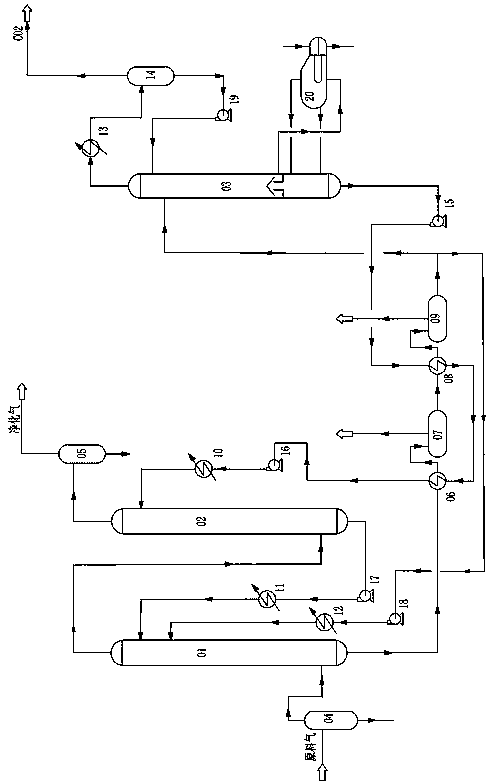

Decarbonization method for producing liquefied natural gas from high-carbon natural gas

A technology of liquefied natural gas and natural gas, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of decarbonization purification degree and processing load contradiction, high regeneration heat consumption and power consumption, low acid gas load, etc. , to achieve the effect of reducing solution circulation, increasing processing load, and good decarburization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mixed gas pressure is 4.0MPa, room temperature, CO 2 The content is 12.0%, the rest is N 2 . The absorption solution of the present invention is composed of 20% aminoethylethanolamine, 20% MDEA, and the rest is water. Under the gas-liquid ratio of the crude absorption tower of 300, the pressure of the high-pressure flash tank is 0.65MPa, 75°C, the pressure of the low-pressure flash tank is 0.15MPa, 90°C, the lean liquid accounts for 1 / 4 of the total amine liquid circulation, and the semi-lean liquid is 45°C. The temperature is 55°C, the CO in the purified gas 2 35ppmv.

Embodiment 2

[0033] Mixed gas pressure is 4.0MPa, room temperature, CO 2 The content is 12.0%, the rest is N 2 . The absorption solution of the present invention is composed of 20% aminoethylethanolamine, 20% MDEA, and the rest is water. Under the gas-liquid ratio of the crude absorption tower of 300, the pressure of the high-pressure flash tank is 0.65MPa, 75°C, the pressure of the low-pressure flash tank is 0.15MPa, 95°C, the lean liquid accounts for 1 / 4 of the total amine liquid circulation, and at 50°C, the semi-lean liquid The temperature is 55°C, the CO in the purified gas 2 20ppmv.

Embodiment 3

[0035] Mixed gas pressure is 4.0MPa, room temperature, CO 2 The content is 12.0%, the rest is N 2 . The absorption solution of the present invention is composed of 25% aminoethylethanolamine, 20% MDEA, and the rest is water. Under the gas-liquid ratio of the crude absorption tower of 350, the pressure of the high-pressure flash tank is 0.70MPa, 75°C, the pressure of the low-pressure flash tank is 0.15MPa, 95°C, the lean liquid accounts for 1 / 4 of the total amine liquid circulation, 55°C, and the semi-lean liquid The temperature is 60°C, the CO in the purified gas 2 20ppmv.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com