Mechanical power head long stroke feeding mechanism and operation method thereof

A technology of mechanical power and feeding mechanism, applied in the field of geological exploration, can solve the problem of not meeting the requirements of medium and deep holes, and achieve the effects of scientific and reliable structure, reliable clamping, and convenient maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

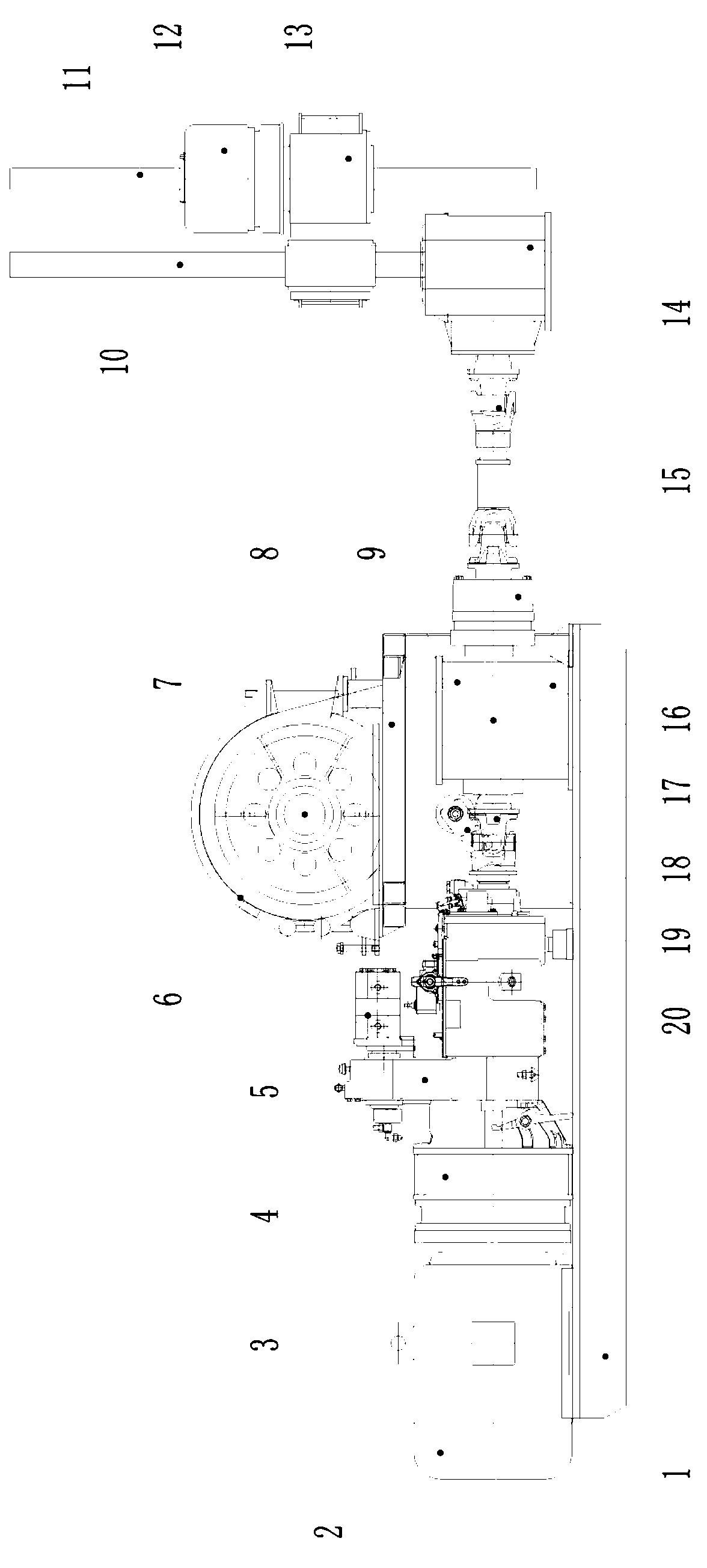

[0026] The main components of a long-stroke feeding mechanism for a mechanical power head include: a universal joint 19, a gear box, a transmission shaft assembly 10, a drill pipe 11, a hydraulic chuck 12, a power head 13, a carriage for the power head, and a cylinder Roller bolt type rollers, slide rails.

[0027] The slide rail is welded and installed on the lower tower body, the power head is fixed on the power head carriage, the cylindrical roller bolt type roller is installed on the power head carriage with bolts, and the power head carriage is fixed and installed on the bore of the feed oil cylinder through the fixing sleeve bracket. In the upper proper position, the power head carriage moves up and down on the guide rail slideway of the lower tower body by means of the cylindrical roller bolt type rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com