Transparent backplane for photovoltaic module and preparation method thereof

A technology of photovoltaic modules and transparent substrates, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of increasing process cost and process difficulty, and achieve the effects of cost control, process easy operation, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

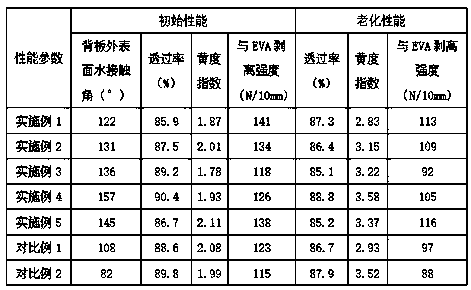

Embodiment 1

[0049] On the outer layer of the double-sided coating type transparent substrate, the casting solution obtained by dissolving 10 parts of polyvinylidene fluoride powder in 100 parts of N,N-dimethylformamide solvent under stirring at 60 ° C, the casting film Add 0.005 parts of fumed silica to the solution, then precipitate and solidify in a water coagulation bath, and then pass through a drying tunnel at 100°C for 3 minutes. A 255 μm thick PET film is selected as the transparent substrate, the thickness of the inner layer of the transparent substrate is 10 μm, the thickness of the outer layer is 2 μm, and the thickness of the coated polyvinylidene fluoride film is 13 μm.

Embodiment 2

[0051] On the outer layer of the double-sided coating type transparent substrate, the casting solution obtained by dissolving 8 parts of polyvinylidene fluoride powder in 100 parts of N,N-dimethylformamide solvent under stirring at room temperature, the casting solution Add 0.01 part of fumed silica, then precipitate and solidify in a coagulation bath of water / ethanol=10 / 1, and then pass through a drying tunnel at 120°C for 3 minutes. A 275 μm thick PET film is selected as the transparent substrate, the thickness of the inner layer of the transparent substrate is 13 μm, the thickness of the outer layer is 3 μm, and the thickness of the coated polyvinylidene fluoride film is 15 μm.

Embodiment 3

[0053] On the outer layer of the double-sided coated transparent substrate, 20 parts of polyvinylidene fluoride powder is dissolved in 100 parts of N,N-dimethylformamide / dimethylsulfoxide=1 / 1 The casting solution obtained from the solvent, 0.5 parts of fumed silica was added to the casting solution, and then precipitated and solidified in a water coagulation bath, and then treated in a 150°C oven for 2 minutes. A 245 μm thick PET film is selected as the transparent substrate, the thickness of the inner layer of the transparent substrate is 5 μm, the thickness of the outer layer is 5 μm, and the thickness of the coated polyvinylidene fluoride film is 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com