Method for preparing iron oxyhydroxide-loaded graphene oxide-layered hydroxide composite material

A technology of layered hydroxide and iron oxyhydroxide, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem of difficult water treatment to meet reuse requirements, low regeneration efficiency of activated carbon, high price, etc. problems, to achieve the effect of increasing the pore size, improving the adsorption performance and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

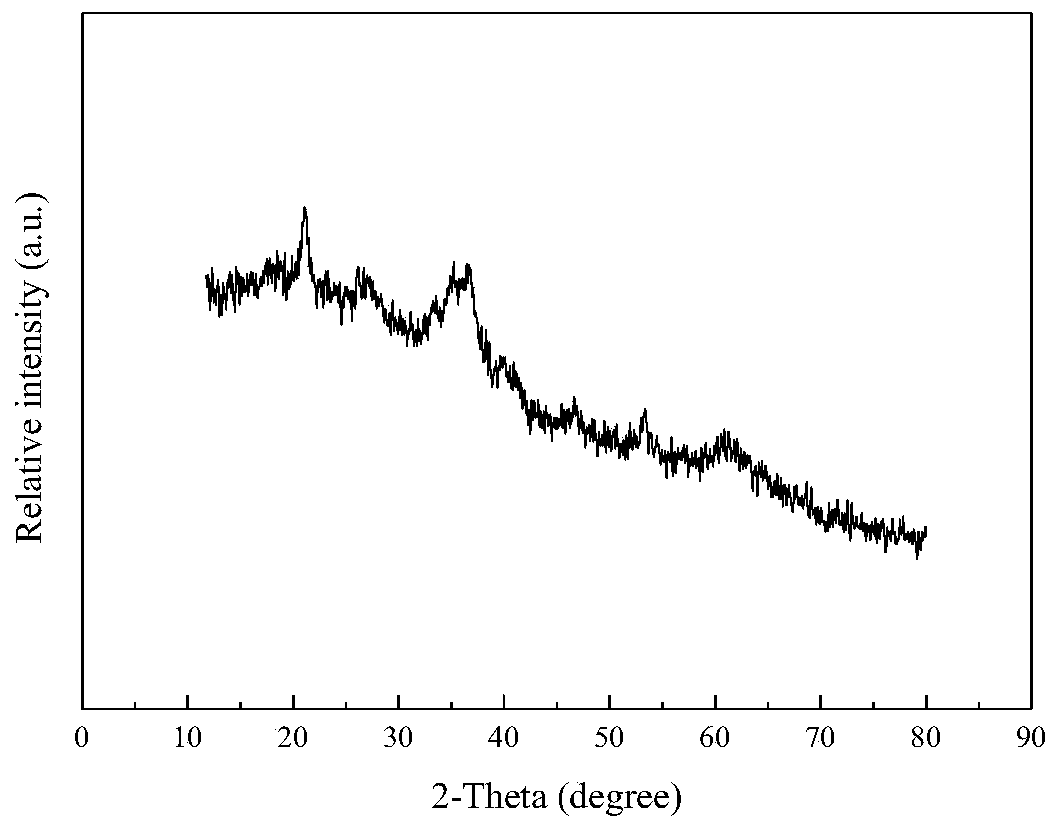

[0031] This embodiment provides a method for preparing a graphene oxide-layered hydroxide-loaded iron oxyhydroxide composite material, and the specific preparation method is as follows:

[0032] Step 1, prepare a graphene oxide suspension with a concentration of 2mg / L, and use water as a dispersant; process it with 150W ultrasonic treatment for 30min to make it uniformly dispersed.

[0033] Step 2, weigh 2.4gNaOH, 2.1gNa 2 CO 3 Prepare alkaline solution, the pH of the alkaline solution is 9-10; weigh 6.1gMgCl 2 ·6H 2 O, 2.2g AlCl 3 ·6H 2 Prepare 100 mL of each metal salt solution of O.

[0034] Step 3: Under stirring conditions, the alkali solution and the metal salt solution are dropped into the graphene oxide suspension at the same time, and the graphene oxide-layered hydroxide composite material is obtained after aging, filtering, washing and drying in sequence. The aging temperature is 25°C, the aging time is 24h, the drying temperature is 65°C, and the drying time i...

Embodiment 2

[0039] This embodiment provides a method for preparing a graphene oxide-layered hydroxide-loaded iron oxyhydroxide composite material, and the specific preparation method is as follows:

[0040] Step 1, prepare a graphene oxide suspension with a concentration of 5mg / L, and use water as a dispersant; process it with 300W ultrasonic treatment for 30min to make it uniformly dispersed.

[0041] Step 2, weigh 3.6g NaOH, 3.2gNa 2 CO 3 Prepare alkaline solution and 8.1gMgCl 2 ·6H 2 O, 4.3g AlCl 3 ·6H 2 Prepare 100 mL of each metal salt solution of O.

[0042]Step 3: Under stirring conditions, the alkali solution and the metal salt solution are dropped into the graphene oxide suspension at the same time, and the graphene oxide-layered hydroxide composite material is obtained after aging, filtering, washing and drying in sequence. The aging temperature is 25° C., the aging time is 24 hours, the drying temperature is 65° C., and the drying time is 24 hours.

[0043] Step 4, prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com