Compact distillation apparatus, and compact distillation system and application thereof

A distillation device and distillation system technology, applied in the field of distillation, can solve the problems of high energy consumption and high requirements for seawater pretreatment, and achieve the effects of reducing energy consumption, inhibiting scaling and corrosion problems, and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Level 5

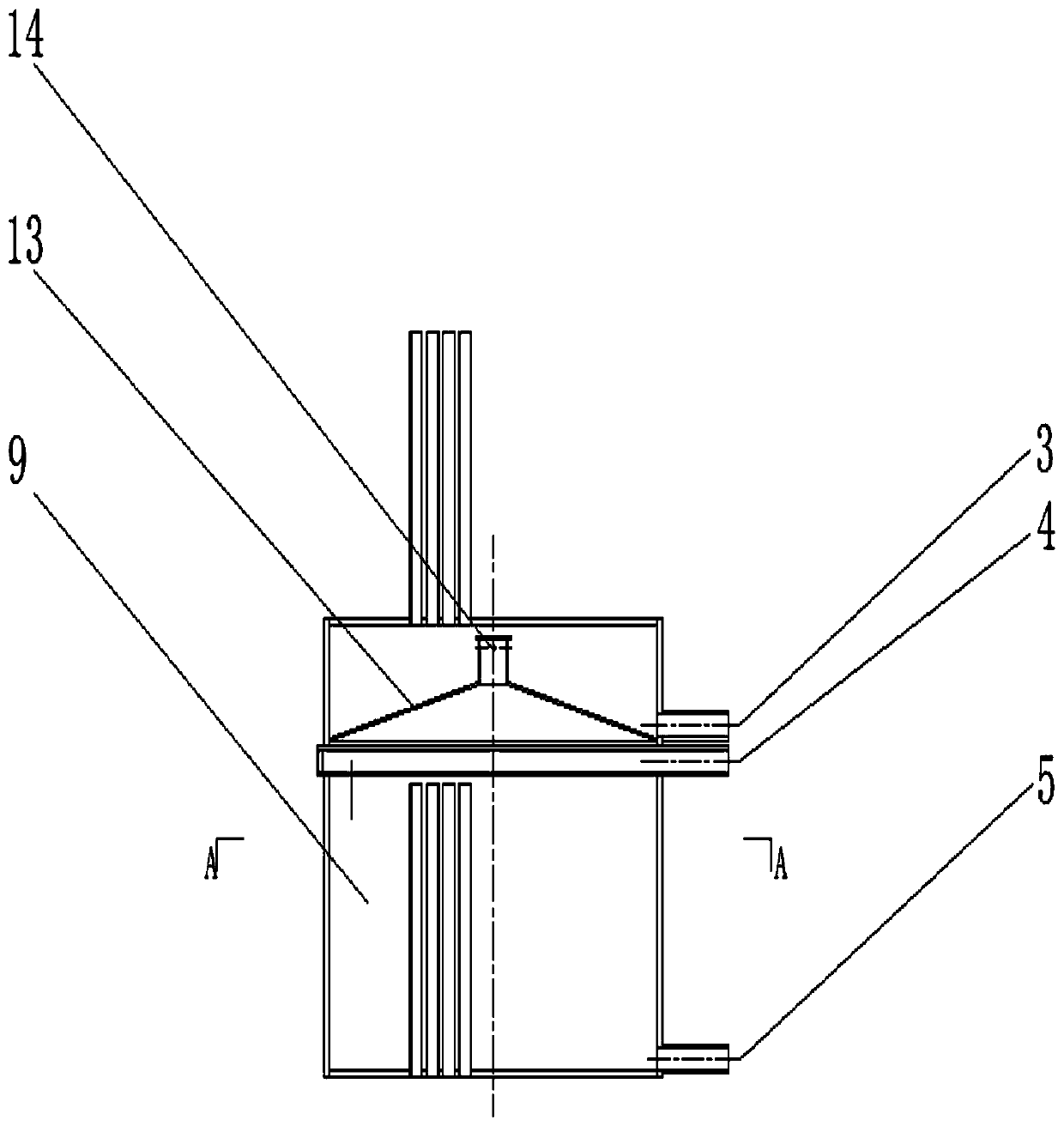

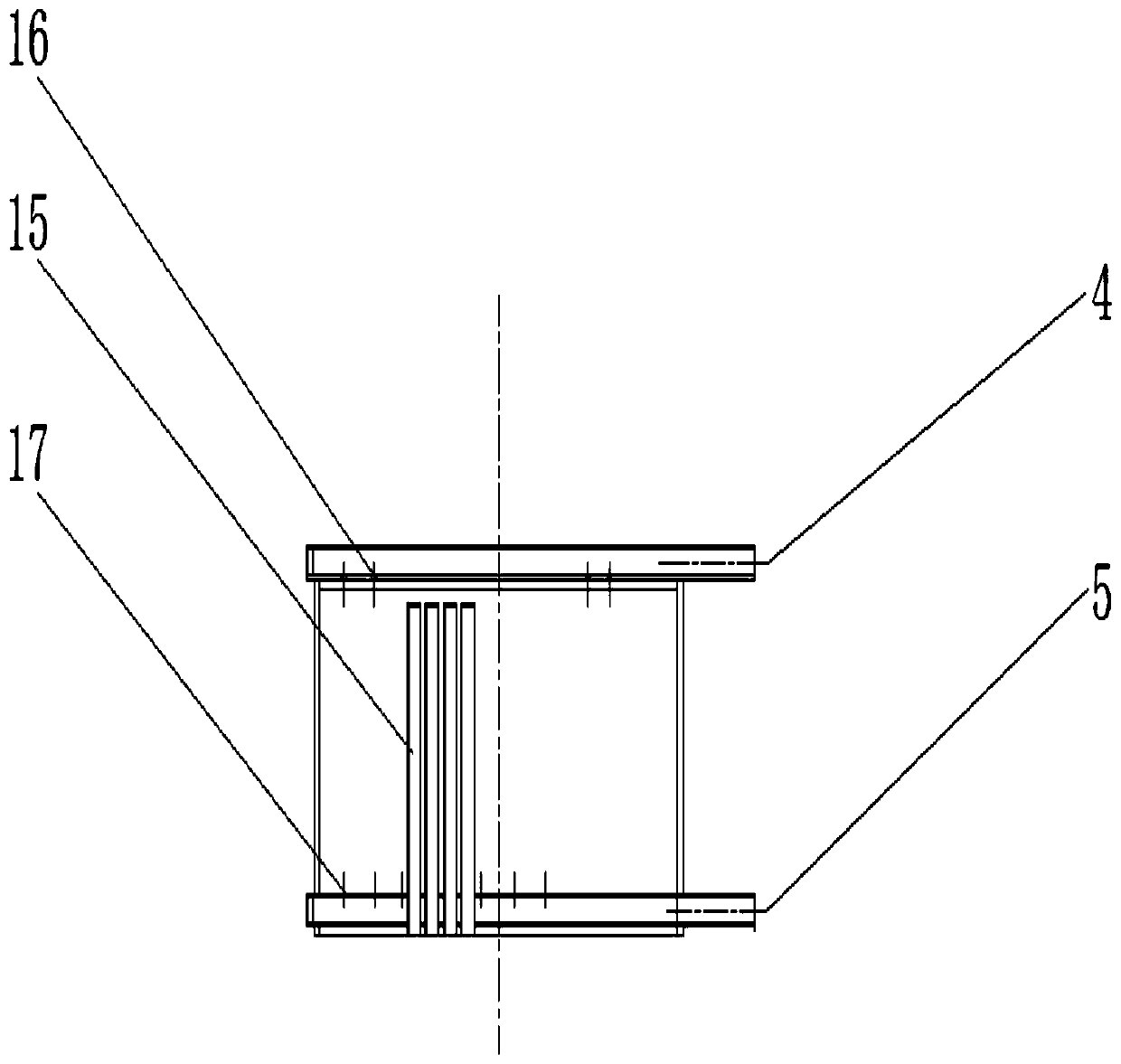

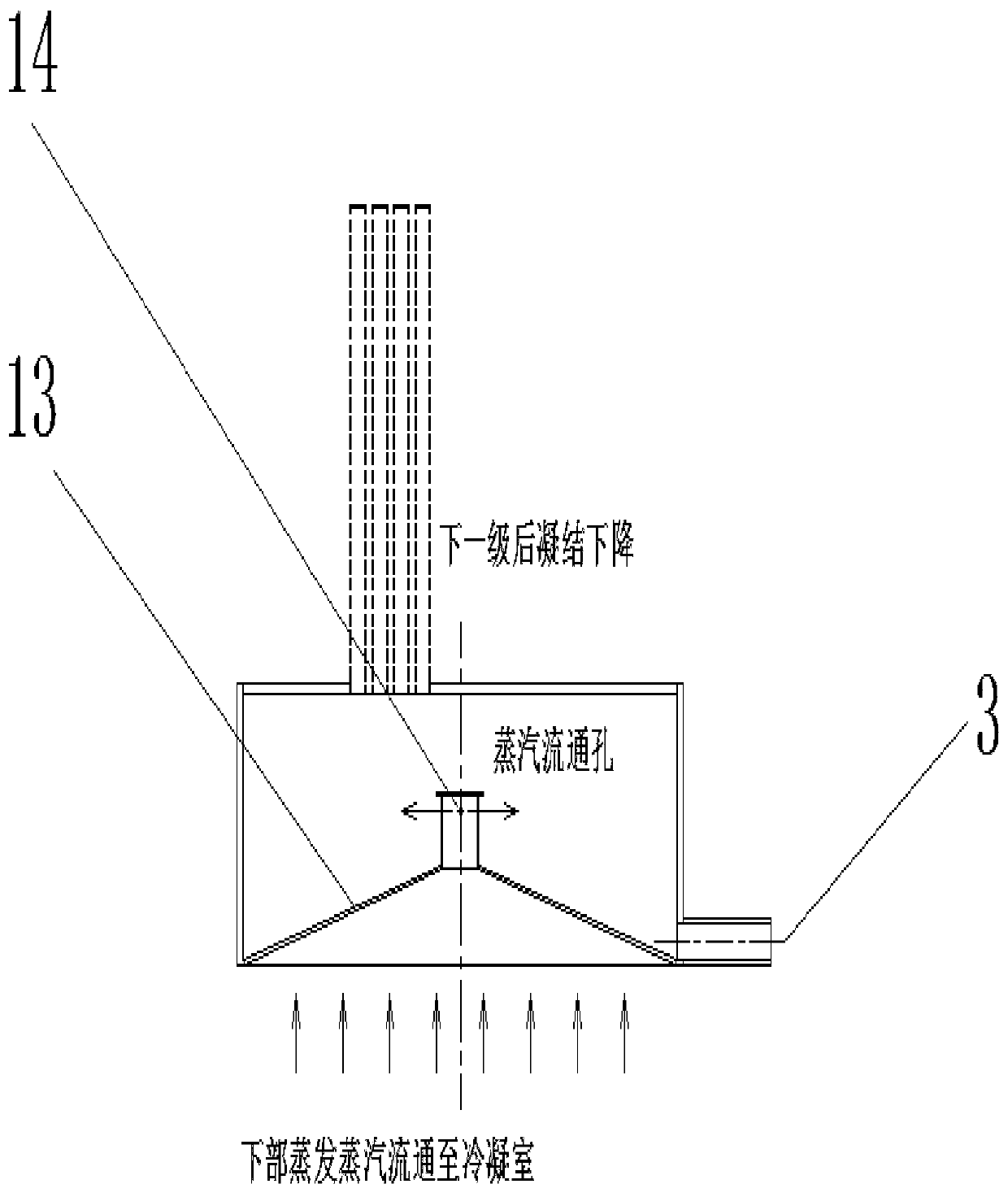

[0076] The five-stage compact distillation units are fixed by flanges, and the first-stage compact distillation unit is connected to a heater to provide a corresponding heat source. The heat source is heated by the first-stage heat conduction sheet 15-1 in the first-stage heating chamber 9-1 of the first-stage compact distillation device, flows from the first-stage seawater inlet 4-1 into the first-stage seawater diversion pipe, and then evenly flows into the first-stage heating chamber 9- 1 seawater, the water vapor formed is output through the 1st-stage steam outlet 14-1 on the 1st-stage steam partition 13-1 and conducts heat in the 2nd-stage heating chamber 9-2 of the 2nd-stage compact distillation device Sheet 15-2 condenses on the first-stage steam separator 13-1 after heat transfer, and flows out from the first-stage clean water outlet 3-1 after gathering. The concentrated sewage deposited after heating in the first-level heating chamber 9-1 is evenly c...

Embodiment 2

[0080] level 10

[0081] The 10-stage compact distillation unit is fixed by welding, and the first-stage compact distillation unit is connected to a heater to provide a corresponding heat source. The heat source is heated by the first-level heat conduction sheet 15-1 in the first-level heating chamber 9-1 of the first-level compact distillation device, flows from the first-level sewage inlet 4-1 into the first-level sewage diversion pipe, and then evenly flows into the first-level heating chamber 9- 1 sewage, the water vapor formed is output through the first-stage steam outlet 14-1 on the first-stage steam partition 13-1 and conducts heat in the second-stage heating chamber 9-2 of the second-stage compact distillation device Sheet 15-2 condenses on the first-stage steam separator 13-1 after heat transfer, and flows out from the first-stage clean water outlet 3-1 after gathering. The concentrated sewage deposited after heating in the first-level heating chamber 9-1 is evenly ...

Embodiment 3

[0085] level 20

[0086] The 20-stage compact distillation units are fixed by welding, and the first-stage compact distillation units are connected to heaters to provide corresponding heat sources. The heat source is heated by the first-level heat conduction sheet 15-1 in the first-level heating chamber 9-1 of the first-level compact distillation device, flows from the first-level river water inlet 4-1 into the first-level river water diversion pipe, and then evenly flows into the first-level heating chamber 9- 1 river water, the water vapor formed is exported through the 1st-stage steam outlet 14-1 on the 1st-stage steam partition 13-1 and conducted in the 2nd-stage heat conduction in the 2nd-stage heating chamber 9-2 of the 2nd-stage compact distillation device Sheet 15-2 condenses on the first-stage steam separator 13-1 after heat transfer, and flows out from the first-stage clean water outlet 3-1 after gathering. The concentrated sewage deposited after heating in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com