Organic fertilizer produced from vitamin fermentation waste, and preparation method thereof

A technology for fermenting waste and organic fertilizers, which is applied in the preparation of organic fertilizers, fertilizers made from biological wastes, and the treatment of biological organic parts. It can solve problems such as pollution, solve industrial pollution problems, realize reuse, and increase enterprises. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

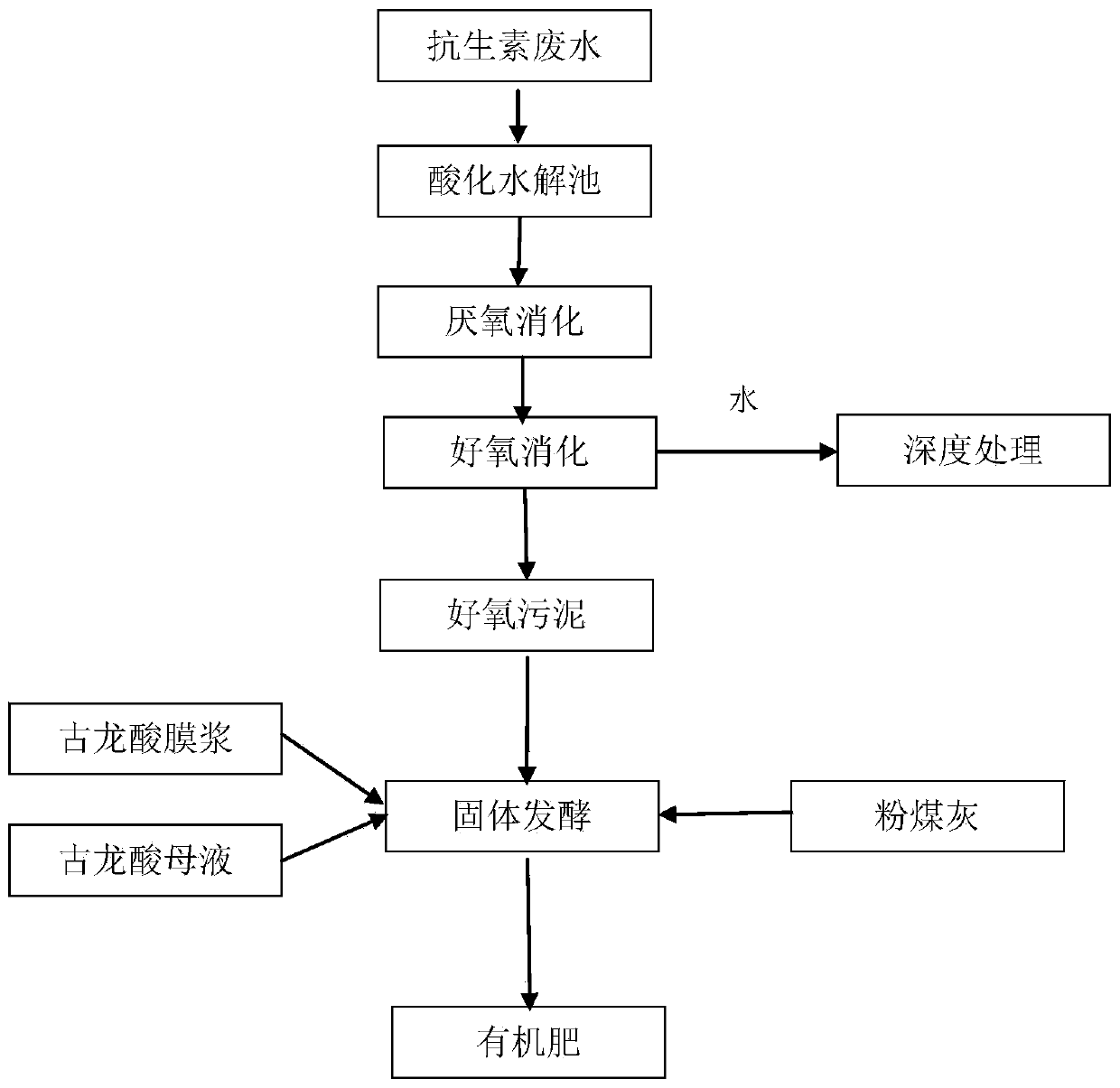

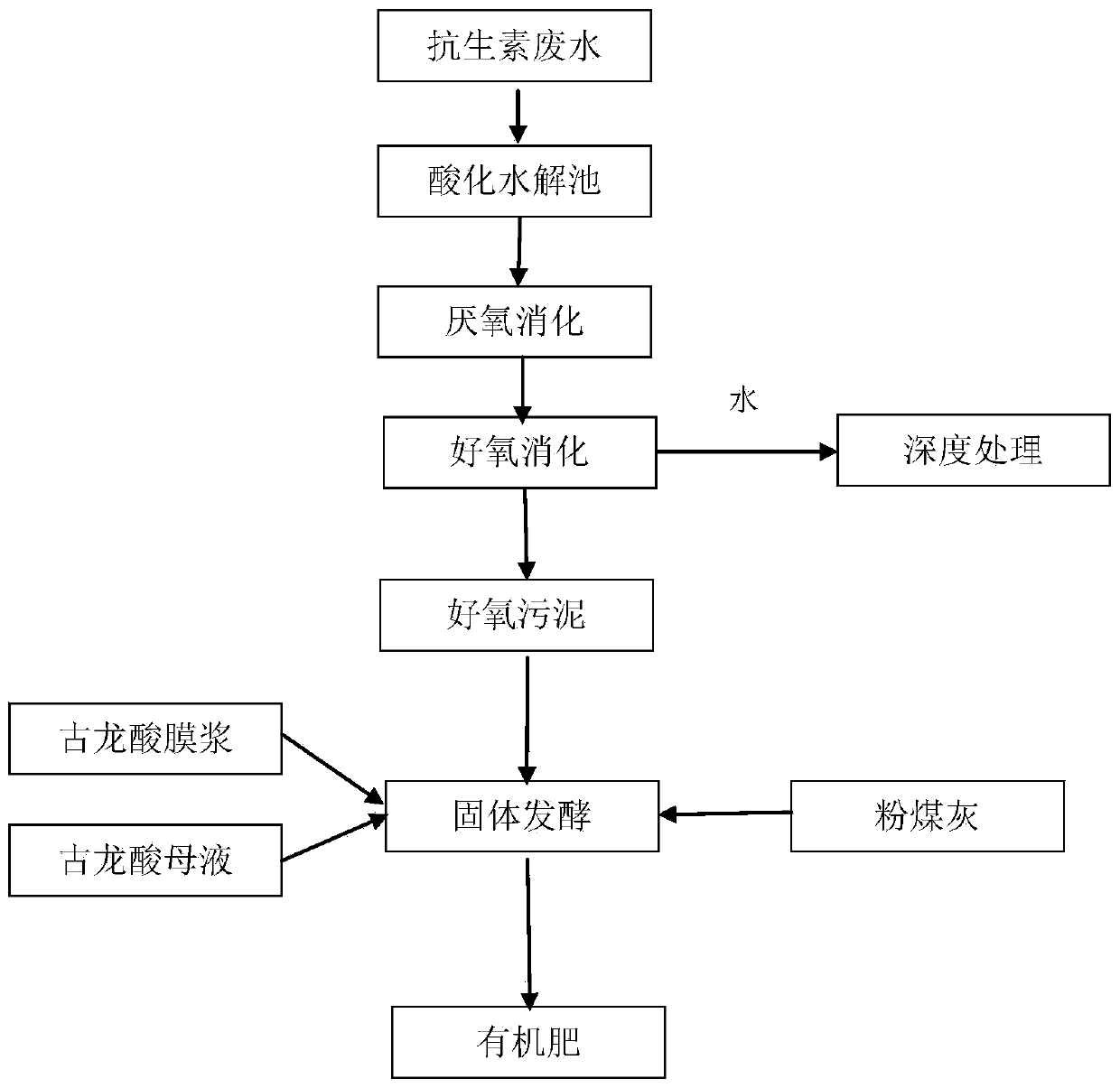

[0026] The combination of different antibiotic wastewater (erythromycin production wastewater and tetracycline production wastewater) is based on 20m 3 / h into the acidification hydrolysis pool, hydrolysis and acidification for 24 hours (stay). Hydrolysis and acidification effluent according to 20m 3 / h into the digestion tank for anaerobic digestion, the volume of the digestion tank is 60000m 3 About, the anaerobic digestion residence time is 100 days. Anaerobic digestion tank effluent according to 20m 3 / h into the aerobic pool, the volume of the aerobic pool is 5000 m 3 About 10 days for aerobic digestion. The sludge at the end of the aerobic tank is settled and flocculated (organic macromolecule flocculation), dehydrated by filter plate frame, and the antibiotic sludge obtained enters the organic fertilizer fermentation link.

[0027] Mix 1.0T of gulonic acid crystallization mother liquor and 1.0T of fly ash and mix evenly, then add 3.0T of gulong acid film slurry and...

Embodiment 2

[0029] Antibiotic wastewater (erythromycin production wastewater) is matched according to 15m 3 / h into the acidification hydrolysis pool, hydrolysis and acidification for 30 hours (stay). Hydrolysis and acidification effluent according to 15m 3 / h into the anaerobic digestion of the digestion tank, the volume of the digestion tank is 60000m 3 Around, anaerobic digestion for 150 days (stay). Anaerobic digestion tank effluent according to 15m 3 / h into the aerobic pool, the volume of the aerobic pool is 5000m 3 Around, aerobic digestion for 16 days (stay). The sludge at the end of the aerobic tank is settled and flocculated (organic macromolecule flocculation), dehydrated by filter plate frame, and the antibiotic sludge obtained enters the organic fertilizer fermentation link.

[0030] Mix 2.0T of gulonic acid crystallization mother liquor and 2.0T of fly ash and mix evenly, then add 2.0T of gulonic acid film slurry and 4.0T of antibiotic sludge and mix evenly, and stack t...

Embodiment 3

[0032] Different antibiotic wastewater (erythromycin production wastewater, tetracycline production wastewater) collocation according to 25m 3 / h into the acidification hydrolysis pool, hydrolysis and acidification for 24 hours (stay). Hydrolysis and acidification effluent according to 25m 3 / h into the anaerobic digestion of the digestion tank, the volume of the digestion tank is 60000m 3 Around, the anaerobic digestion residence time is 96 days (residence). Anaerobic digestion tank effluent 25m 3 / h into the aerobic pool, the volume of the aerobic pool is 6000m 3 About 10 days of aerobic digestion (residence), the sludge at the end of the aerobic tank is settled, flocculated (organic macromolecule flocculation), dehydrated by filter plate frame, and the obtained antibiotic sludge enters the organic fertilizer fermentation link.

[0033] Mix 0.3T of gulonic acid crystallization mother liquor and 0.7T of fly ash and mix evenly, then add 1T of gulong acid film slurry and 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com