Anti-impact super-tough lens material and preparation method thereof

An impact-resistant and super-tough technology, applied in the field of lenses, can solve the problems of reduced impact strength, reduced impact resistance of lenses, unsatisfactory adhesion between wear-resistant coatings and primers, etc., to achieve improved attachment Effects of poor grip, excellent abrasion resistance, and excellent UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

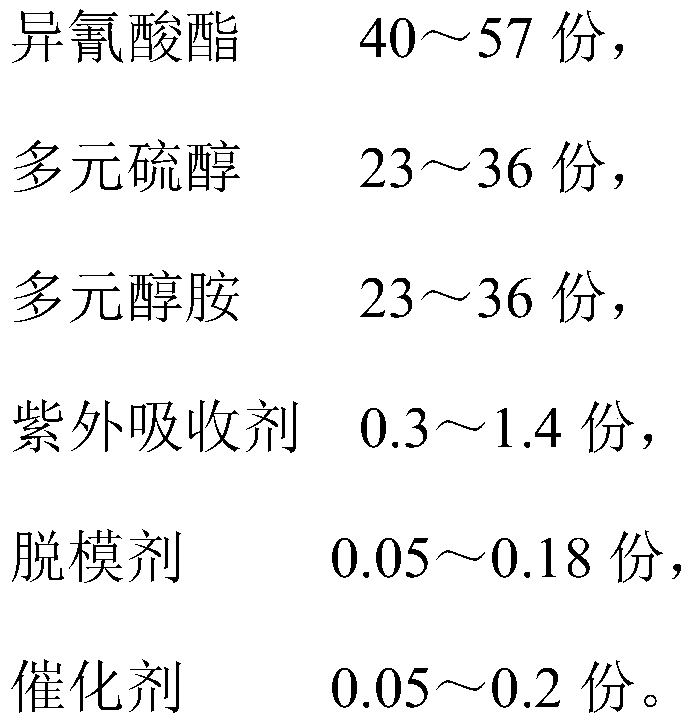

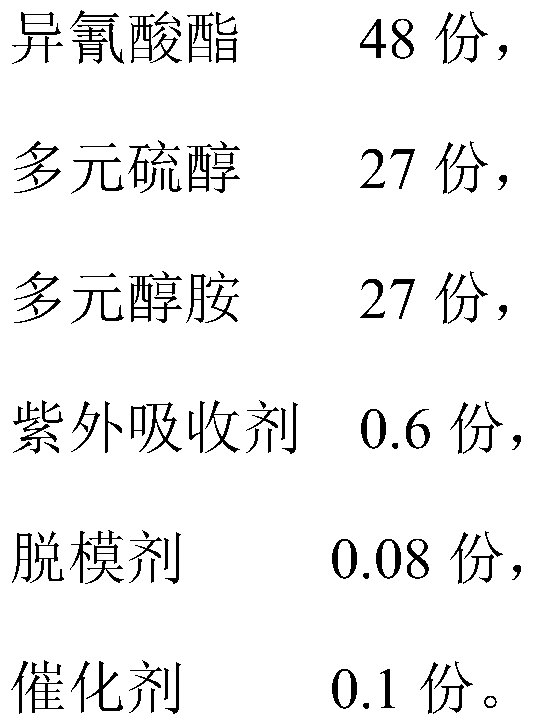

[0028] 1, the consumption of raw material is as follows in the present embodiment:

[0029] Isocyanates: 4,4-dicyclohexylmethane diisocyanate (20g), hexamethylene diisocyanate (28g);

[0030] Polymercaptans: pentaerythritol tetrakis(3-mercaptopropionate) (13.5g) and thiodiglycol (13.5g);

[0031] Polyolamine: bis(2-hydroxymethyl)amino-tris(hydroxymethyl)methane (27g);

[0032] UV absorber: 2-(2'-hydroxyl-5'-tert-octylphenyl)benzotriazole (0.6g);

[0033] Release agent: HILUB-67 (0.08g);

[0034] Catalyst: isopropyl titanate (0.1 g).

[0035] 2. Preparation method

[0036] S1. Weigh each component in proportion, mix and stir the isocyanate and catalyst, then add UV absorber and release agent in sequence, after vacuum defoaming at 25°C for 70 minutes, add polythiol and polyol amine, mix and stir Vacuum defoaming at 18°C for 35 minutes, then vacuum defoaming again for 15 minutes after stopping stirring, to obtain the resin lens composition ingredients;

[0037] S2. Dry ni...

Embodiment 2

[0039] 1, the consumption of raw material is as follows in the present embodiment:

[0040] Isocyanates: 4,4-dicyclohexylmethane diisocyanate (20g), hexamethylene diisocyanate (28g);

[0041] Polymercaptans: pentaerythritol tetrakis(3-mercaptopropionate) (13.5g) and thiodiglycol (13.5g);

[0042] Polyolamine: Bis(2-hydroxymethyl)amino-tris(hydroxymethyl)methane (27g);

[0043]UV absorber: 2-(2'-hydroxyl-5'-tert-octylphenyl)benzotriazole (0.6g);

[0044] Release agent: HILUB-67 (0.08g);

[0045] Catalyst: isopropyl titanate (0.1 g).

[0046] 2. Preparation method

[0047] S1. After mixing and stirring isocyanate and catalyst, add UV absorber and mold release agent in sequence, after vacuum degassing at 28°C for 50 minutes, add polythiol and polyol amine, mix, and vacuum defoam at 22°C for 30 minutes while stirring, After stopping the stirring, vacuum defoaming again for 10 minutes to obtain the resin lens composition ingredients;

[0048] S2. Dry nitrogen and pressurize, ...

Embodiment 3

[0050] 1, the consumption of raw material is as follows in the present embodiment:

[0051] Isocyanates: 4,4-dicyclohexylmethane diisocyanate (20g), hexamethylene diisocyanate (20g);

[0052] Polymercaptans: pentaerythritol tetrakis(3-mercaptopropionate) (27g) and thiodiethylene glycol (9g);

[0053] Polyolamine: Bis(2-hydroxymethyl)amino-tris(hydroxymethyl)methane (23g);

[0054] UV absorber: 2-(2'-hydroxyl-5'-tert-octylphenyl)benzotriazole (0.3g);

[0055] Release agent: HILUB-67 (0.18g);

[0056] Catalyst: isopropyl titanate (0.05 g).

[0057] 2. Preparation method

[0058] S1. Weigh each component in proportion, mix and stir the isocyanate and catalyst, then add UV absorber and mold release agent in turn, after vacuum defoaming at 25°C for 70 minutes, add polythiol and polyol amine, mix and stir Vacuum defoaming at 18°C for 35 minutes, then vacuum defoaming again for 15 minutes after stopping stirring, to obtain the resin lens composition ingredients;

[0059] S2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com