A preparation method of waveguide bright anodic oxidation thermal control coating

A technology of anodic oxidation and thermal control coating, which is applied in the field of spacecraft to achieve the effect of continuous coating, high product qualification rate and good quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

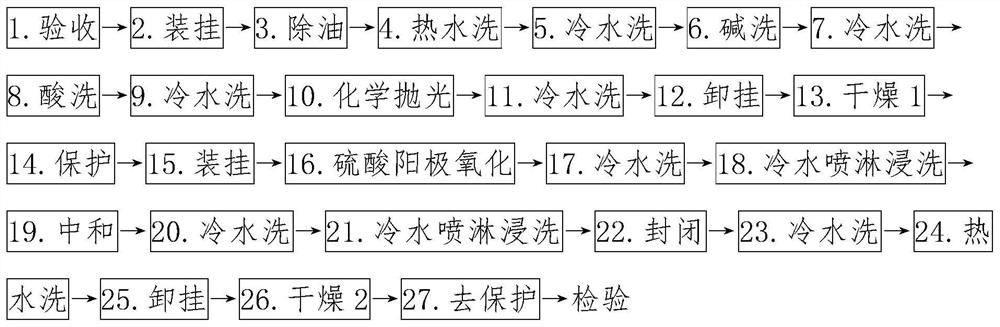

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

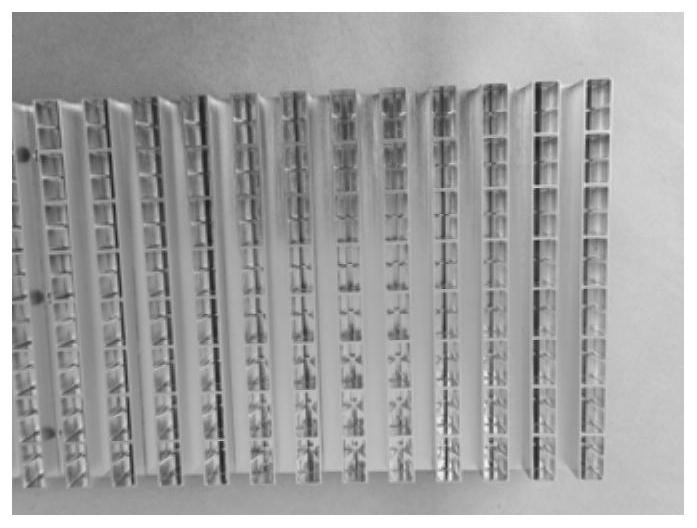

[0034] A satellite SAR antenna waveguide (radiating element) is taken as an example for illustration. The satellite SAR antenna waveguide is formed by machining and brazing of multiple aluminum-manganese aluminum alloy thin-walled parts. The structure is complex and the precision is high. Its local shape is as follows: figure 1 shown. The thermal control design requirements of the waveguide in this embodiment are: bright anodic oxidation thermal control coating treatment is carried out on the surface except the inner wall of the bell mouth and the inner cavity, and the solar absorption ratio of the thermal control coating is required to be α s =0.23±0.02, hemispherical emissivity ε H =0.43±0.02.

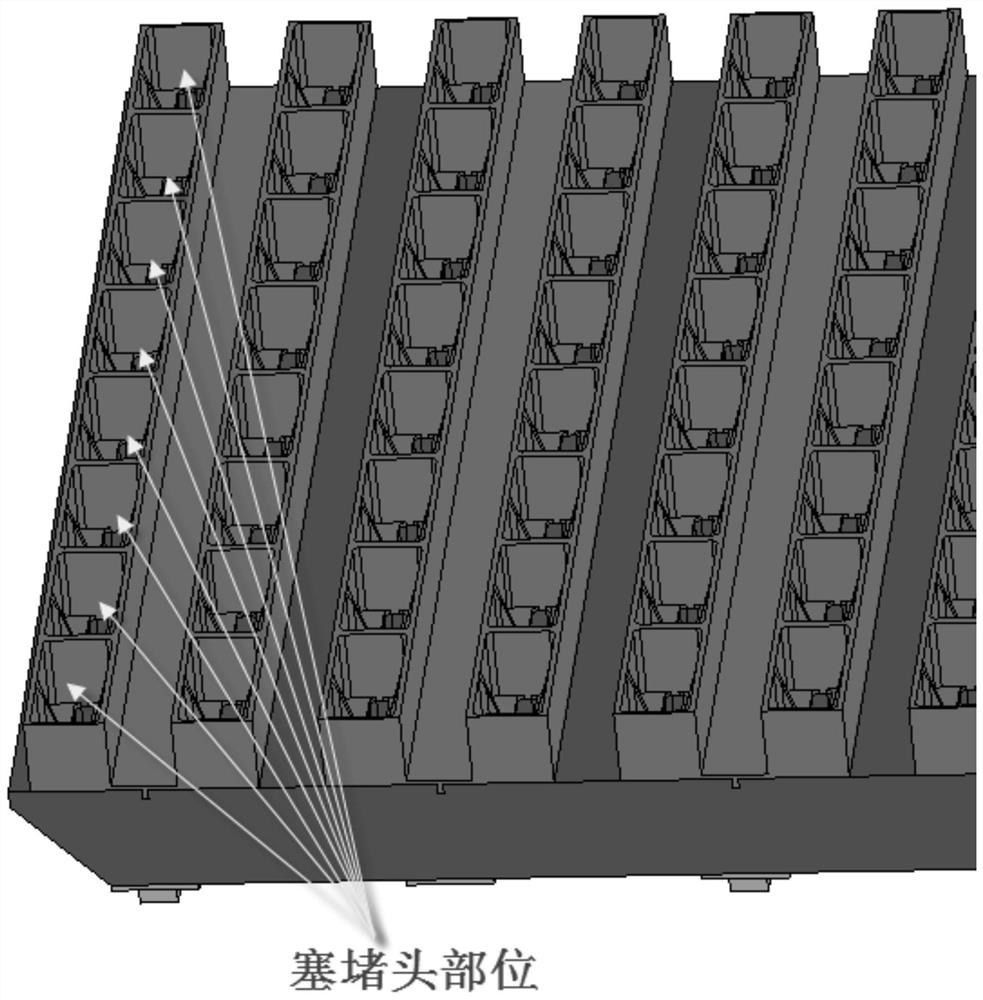

[0035] The front of the antenna waveguide has multiple rows of front-en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com